Chemical Equipment Technology Center

Utilities to assist your business development (Chemical Equipment Technology Center)

We have experimental facilities for evaporators and polymerizers with unique functions, which contribute to the realization of our customers' novel approaches to manufacturing new materials such as bioplastics and electronic materials, as well as recycling and process improvement.

Thin Film Evaporator

-

Thin film evaporators are capable of evaporating and separating high-viscosity liquids, slurry liquids, and thermally unstable substances that are difficult to handle in shell & tube heat exchangers. Batch operation concentration using an agitator tank may be converted to continuous operation using this equipment.

-

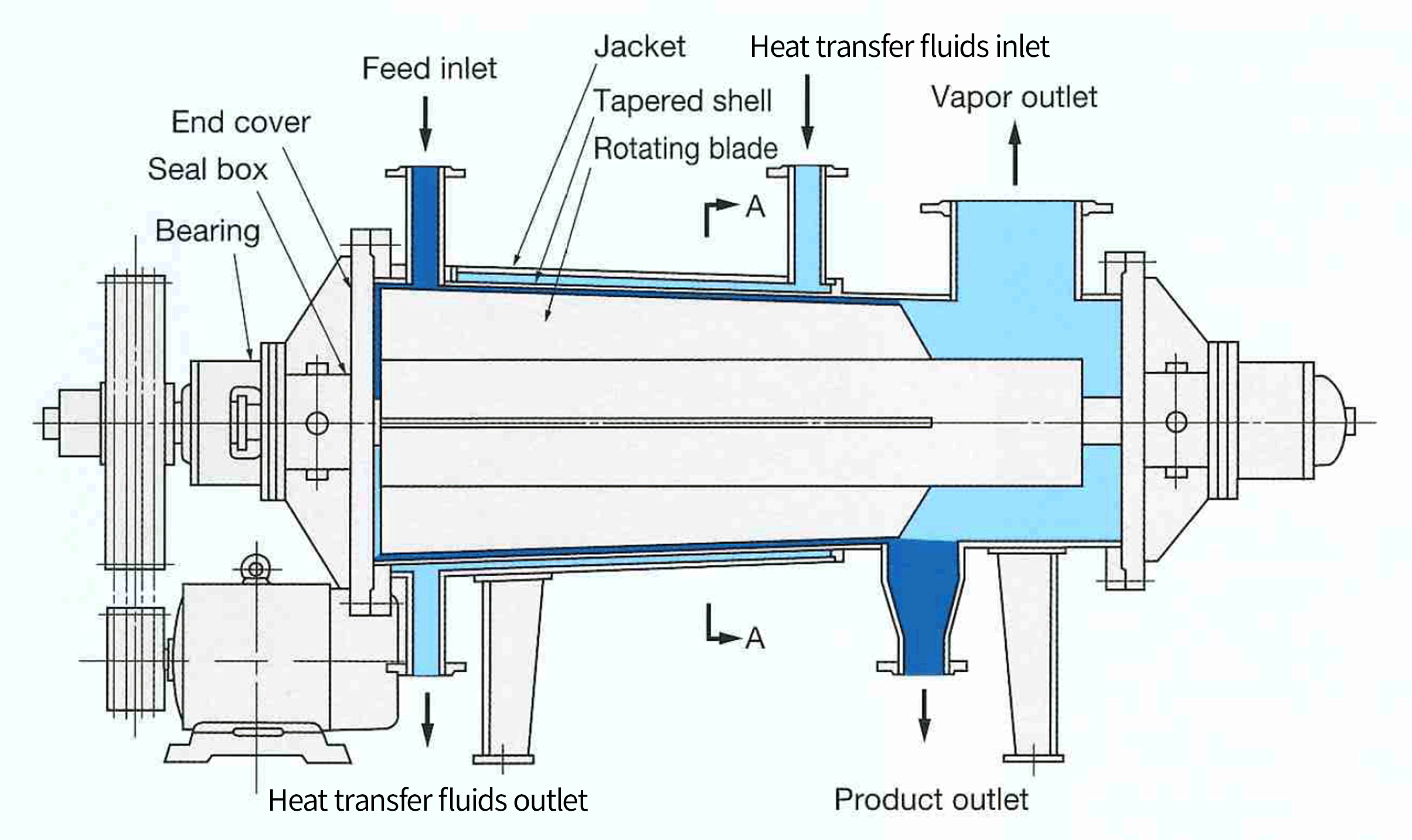

Horizontal Thin Film Evaporator

The horizontal type is characterized by a narrowing of the body toward the outlet, which prevents the liquid film from running out even with high concentration. There is also a sanitary type that can be opened easily. Experiments are conducted to confirm product quality, search for optimal operating conditions, and collect sizing data.

-

Vertical Thin Film Evaporator

The vertical type is not affected by shaft deflection due to gravity, so it is possible to manufacture larger equipment than the horizontal type. In addition to rotary blades with clearance between the shell and the rotor blades, we also have rotary blades (Sevcon) with no clearance, allowing experiments with liquids containing solids, such as slurry liquids.

Polymerizer for high viscosity

-

The polymerizer for high viscosity is a polymerizer that efficiently mixes ultra-high viscosity liquids up to 2,000 Pa-s and is used in the production of polyester, engineering plastics and bioplastics. Experiments are conducted to confirm product quality, search for optimal operating conditions, and collect sizing data.