carbon-neutral

carbon-neutral

Businesses based on environmental considerations, such as accelerating shift to xEVs and expanding investment in green energy, are attracting attention, and we provide the seeds to contribute to these efforts and help our customers transform their businesses.

Energy Structure Transformation Needs

-

Structural Materials for Offshore Wind Power Generator

We are good at manufacturing kilns and other large cylindrical equipment for cement plants, and are currently manufacturing "transition pieces" and other products for offshore wind power projects, taking advantage of our ability to ship large products in their finished form at sea.

-

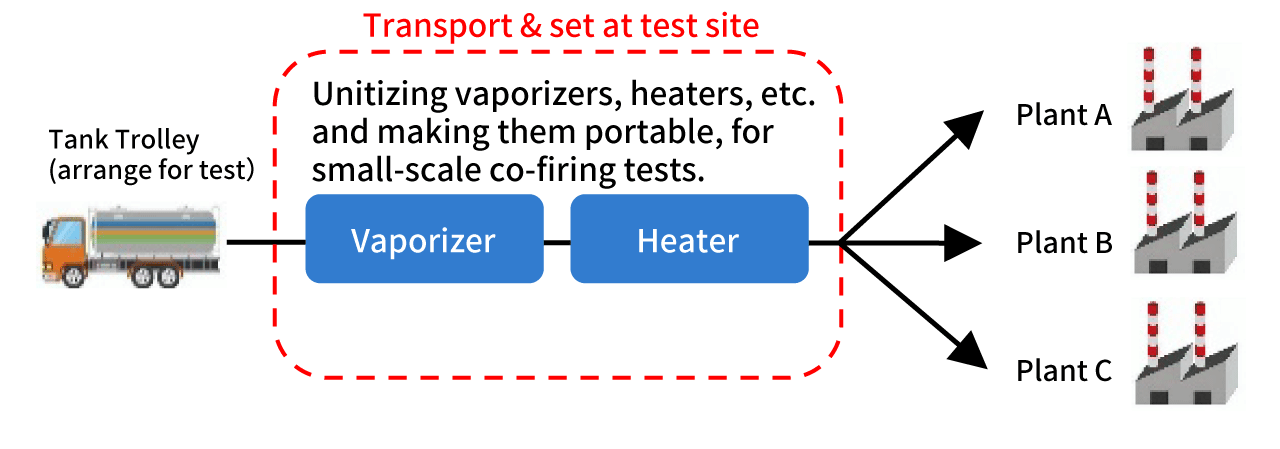

Fuel ammonia supply system

Liquid ammonia is attracting attention as an alternative energy source to fossil fuels, and we propose systems that can be provided as a package, such as a portable ammonia supply system that is small enough to fit into a small space, taking advantage of our experience at UBE.

-

Materials for Low-Temperature, High-Pressure Compressors

We are working with our customers to explore the possibilities of new applications for low-temperature, high-pressure cast steel developed for power generation (LNG compressors), including the development of large refrigerant compressors for liquid ammonia production, for which needs are expected to expand.

-

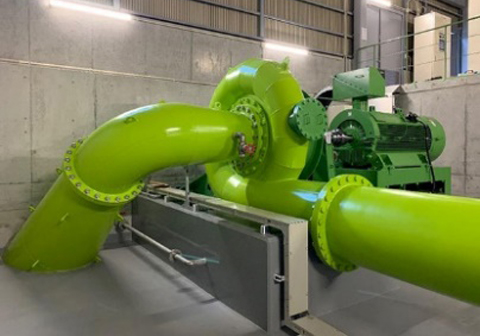

Hydroelectric Power Generation Equipment

We are developing our auxiliary equipment manufacturing and service business in cooperation with major general construction consultants for hydraulic power generation, which is once again attracting attention as a green energy source, and we aim not only to maintain stable operation but also to provide value-added proposals.

Accelerated xEV conversion

-

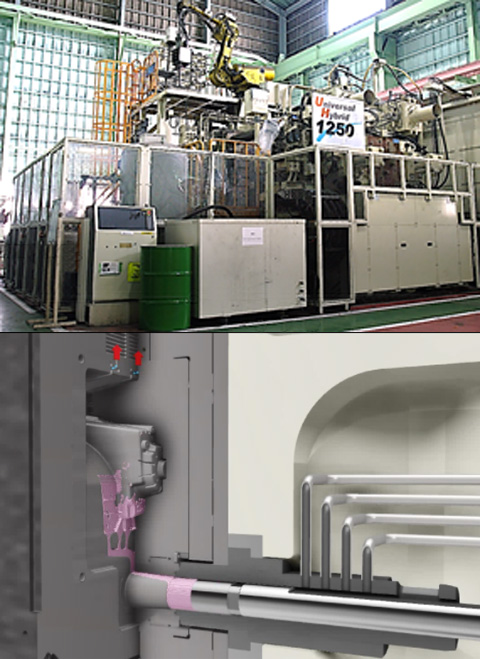

Energy-saving package to meet the needs of parts manufacturing for xEV

The industry's top-class high-cycle die casting is realized at high cost performance, and contributes to CN as an energy-saving means of parts manufacturing for xEV through stable operation by AI and energy-saving and high-cycle operation in a series of movement of core, spray, and ladling.

-

Support for Large Structural Parts

Integration of automotive structural components, which eliminates the need for alignment technology, is beginning to spread mainly overseas, but there are many issues in terms of quality and weight reduction. We will propose realistic solutions through the development of various elemental technologies and processes.

-

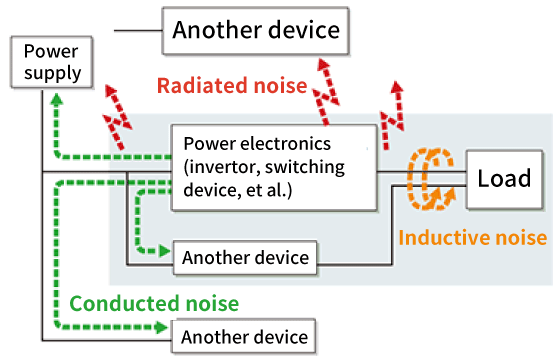

High-frequency Resistor Filter

We propose switching noise suppression (high-frequency filter), one of the large motor utilization technologies developed for large electric injection molding machines, as an important key factor for other applications that require higher voltage and higher responsiveness.

Growing need for energy conservation in existing facilities

-

Reduction of CO2 emissions in existing facilities

Existing equipment can also be made energy efficient by making partial modifications, such as changing hydraulic pumps to servo-driven speed control (top left), conventional servo valves to servo motor driven valve (bottom left), and hydraulic cylinders to electric drive.

-

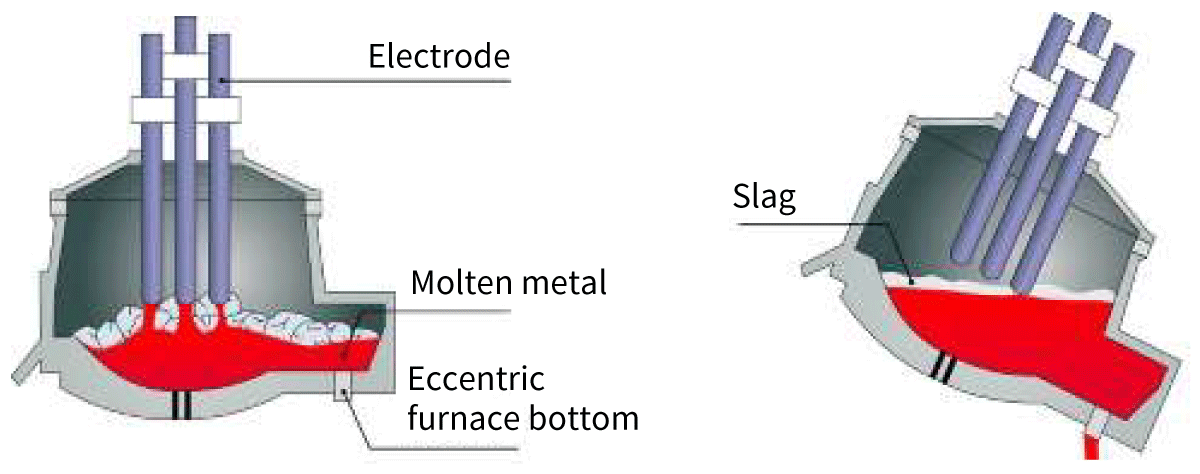

Introduction of energy-saving electric furnace (billet manufacturing)

The electric arc furnace emits 1/4 or less of CO2 during billet manufacturing compared to the blast furnace. To further improve melting efficiency, various innovations such as high-temperature preheating of raw material scrap and efficient placement of arc electrodes are used.