DC Solution Center

Utilities to assist your business development (DC)

To contribute to a carbon-neutral society by 2050, we provide die casting machine equipment that embodies the environmentally friendly development technologies demanded by the times, including the shift to EVs for automobiles.

1. Test Casting Equipment

-

UH1250

This is a hydraulic/electric hybrid die casting machine that saves energy by adopting an electric die open/close mechanism and saves space by using two platens. Equipped with a high filling force injection device "Extreme Shot", this machine is suitable for trials to achieve short-time filling of ultra-thin-walled products.

-

UB530iS3 & UB850iS3

UB-iS3 is a standard model of medium-sized die casting machine. The DC Solution Center is equipped with a 530-ton and an 850-ton die clamping force machine, and customers are invited to bring in their target die cast products for trial casting and testing when considering the introduction of the UB-iS3 series. The 850-ton machine is a high-cycle specification that incorporates our latest technology, and its effectiveness can be confirmed through an actual casting demo operation.

-

M-HFC

This is a model developed by our company that achieves high quality and high productivity of thick-walled high-strength castings. It is available for various casting tests that contribute to the promotion of weight reduction of suspension parts and pressure-tight parts manufactured by low-pressure casting and gravity casting.

2. Die Casting School

-

This Die Casting School has a long history and a proven track record, having held more than 150 sessions since its initial opening in 1988. Our classroom lectures and practical training courses by experts in the fields of design, maintenance, and casting have earned a solid reputation over the years. Depending on the purpose and ability of the student, the Maintenance Course or the Casting Engineer Course can be selected.

3. New and One-of-a-Kind Technology

-

High cycle UB850iS3

The accumulated die casting machine technology has been applied to achieve the industry's top class high cycle. The high-cycle iS3 series contributes to carbon neutrality as a means of saving energy in the manufacture of die-cast housings for electric vehicles.

-

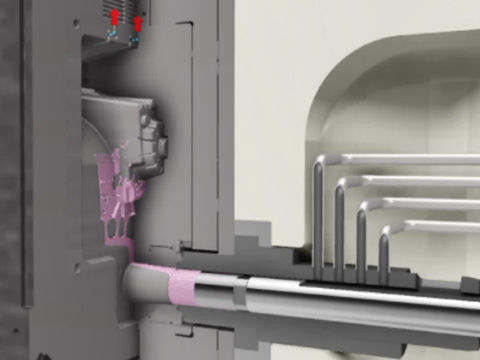

Sleeve vacuum

This is our sleeve vacuum system that eliminates aluminum clogging trouble during sleeve depressurization, which is inevitable for high-vacuum die casting, with our revolutionary technology. This system is effective in improving the quality of large body and chassis die-cast parts and the non-defective product rate, as well as suppressing the splashing of hot metal in the cavity, which is the main cause of cold flake in vacuum die-casting.

-

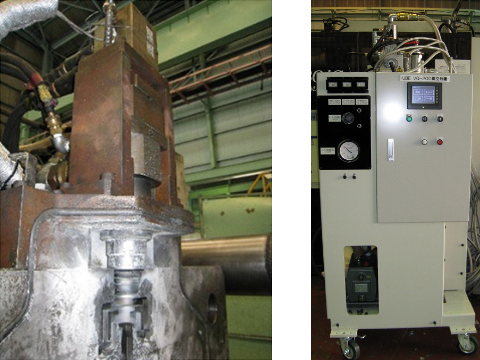

GF GFーMAX

GF is the world famous die vacuum system having a long track record and reliability. We offer models according to the specifications and sizes of the target die casting products.

-

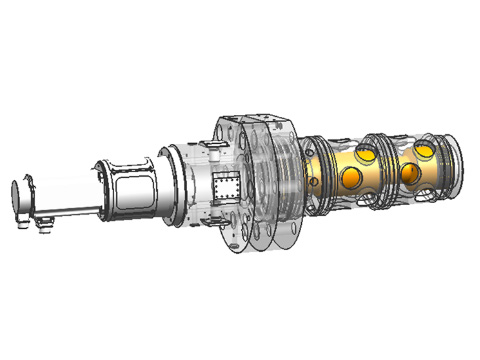

HS-DDV

This is a large flow servo valve developed and manufactured in-house by our company to achieve ultra high-speed injection with high accuracy. It is mounted on all large die casting machines with ultra-high speed injection specifications, and demonstrates stable injection performance from low speed to ultra-high speed range.

-

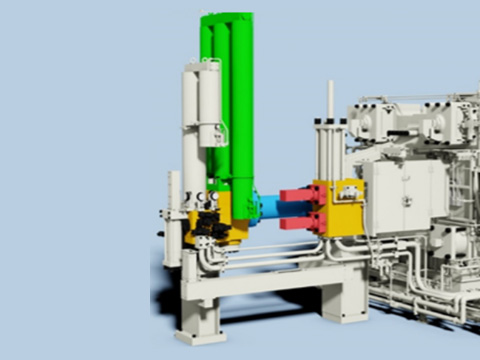

Extreme Shot

This injection system provides high filling force and improved injection speed performance to cope with the molten metal filling resistance that tends to increase as die cast parts become larger and thinner due to the integration of multiple parts. It realizes short-time filling of the above component groups.

-

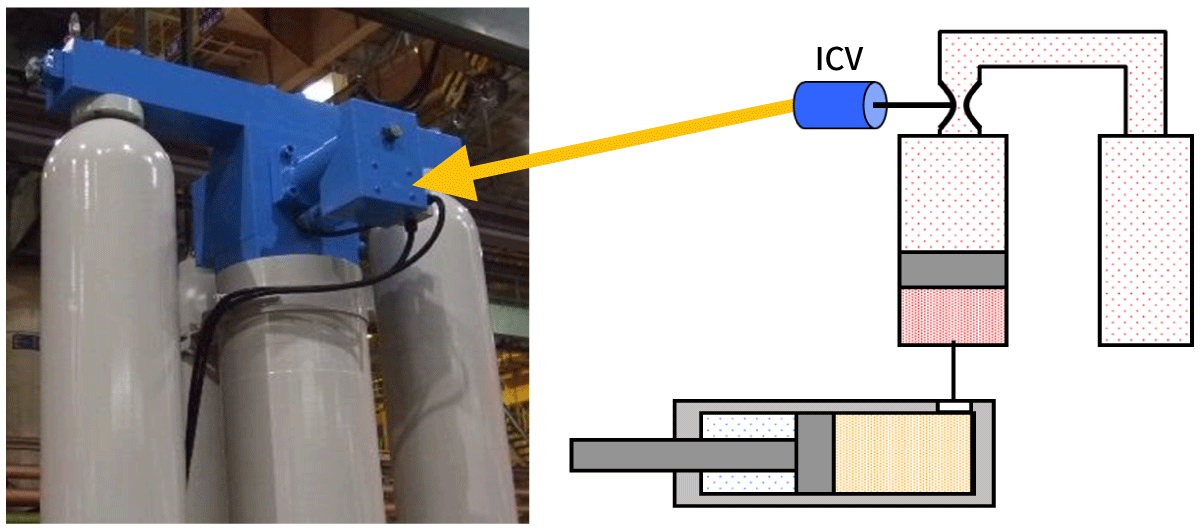

Impact Control

This is an optional function for simple and easy control of casting burr conditions. It is possible to prevent casting burrs by adjusting the gas pressure of the filling accumulator to an appropriate level with a single parameter.

4. Casting Technical Support Services

-

The experienced staff of the Cast Solution Group will support various troubles and defects that occur in die casting and smooth start-up of casting when introducing a new die casting machine.

5. Fundamental Technologies Supporting R&D

-

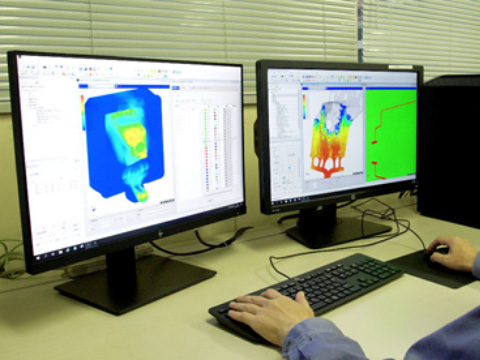

Casting Analysis Technology

Casting Simulation System 『ADSTEFAN』This is an effective flow and solidification analysis system for studying the optimum casting method for the target die cast product and for case studies to determine the cause of casting defects and countermeasures. Our Cast Solution Group provides high-precision solutions based on our extensive experience in analysis.

-

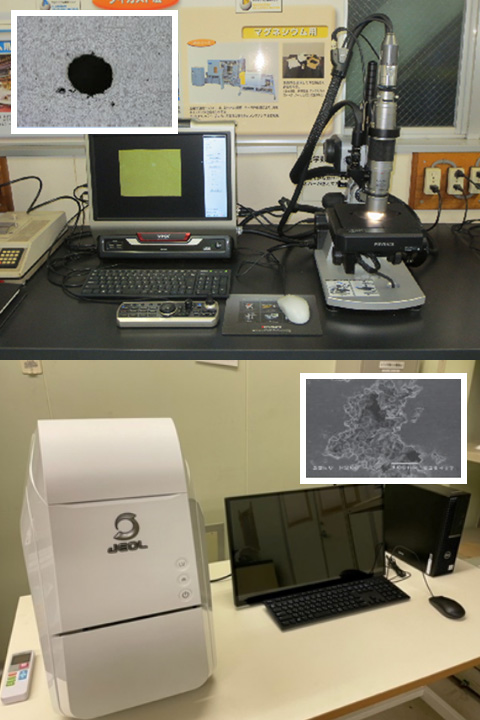

Die-cast product evaluation technologies

Our analytical equipment, including X-ray, gas analysis equipment, and various microscopes, as well as our long-accumulated material evaluation technology, contribute to the derivation of new die casting technologies and solutions to customer issues.