Digital transformation (DX)

Digital transformation (DX)

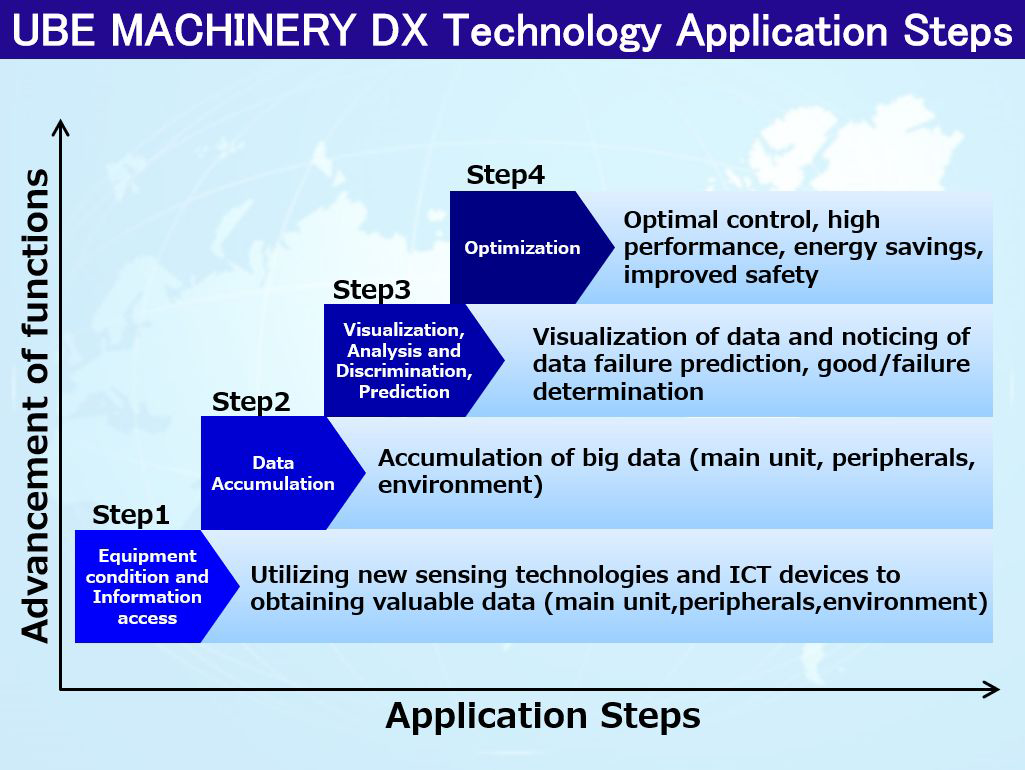

UBE Machinery applies DX technology to the development of products and services that meet customer needs, and offers them to customers under the trademark "DX Supporter". We collect and accumulate data on machines, peripheral equipment, products, and the environment, and analyze big data to realize preventive maintenance and good/fail judgment. DX technology is being applied to preventive maintenance and quality control of machines in the process machinery business, and to the realization of diverse customer needs for each machine model in the industrial machinery business. We also apply DX technology to improve productivity and operations within the company.

1. Process Machinery DX Technology

-

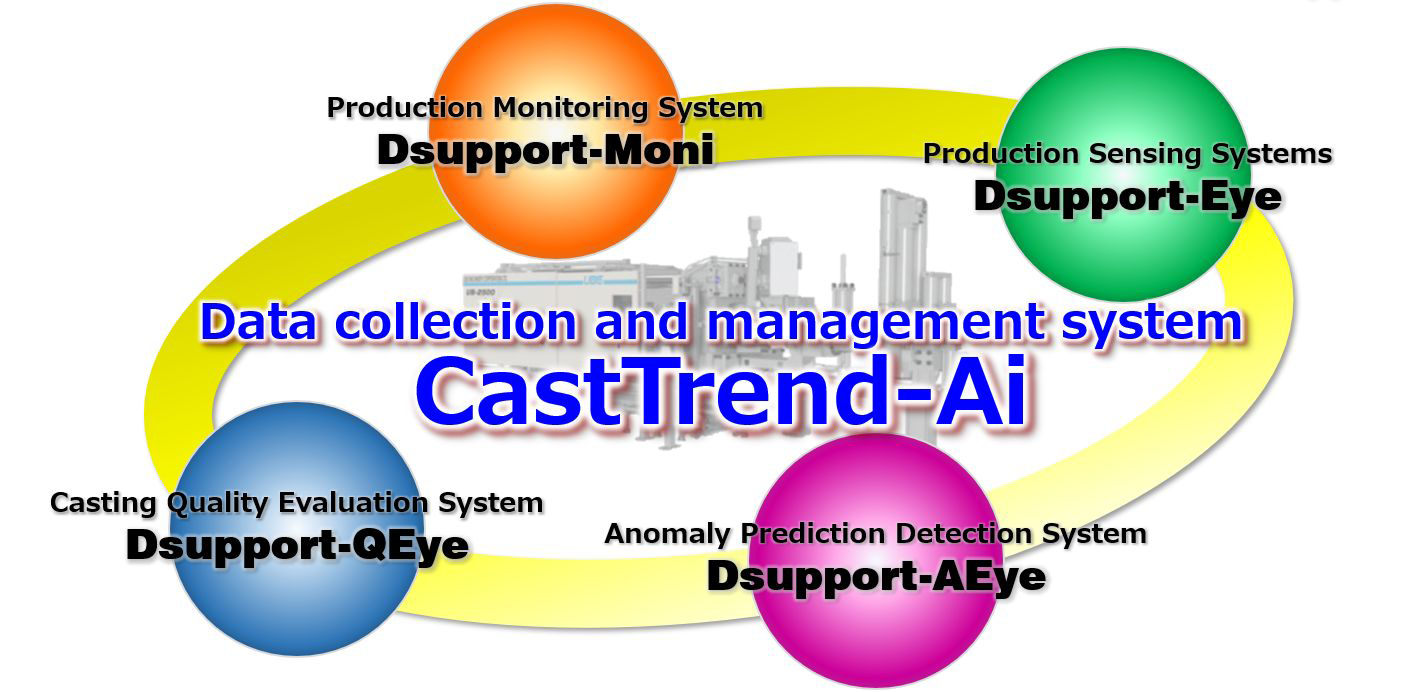

Die casting machine

Operator friendly and Casting easy to understand are the concept our DX system based on. It supports casting operators and contributes to stable operation of die casting machines, productivity improvement, and quality improvement of cast products.

-

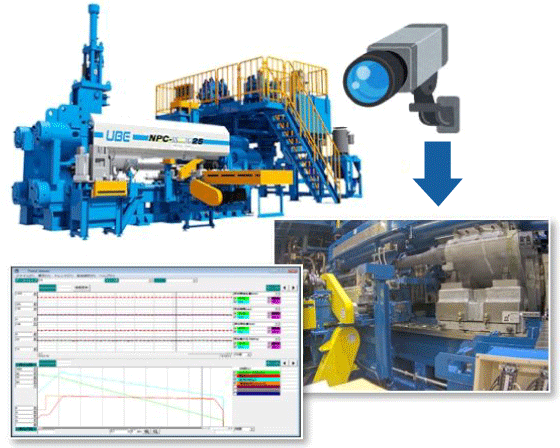

Extrusion press

Making the quality information management system "PressTrend" evolved, and providing systems and services that link extrusion data with Image and video recording, we help our customers make their smart factories, contributing to improved quality and productivity.

-

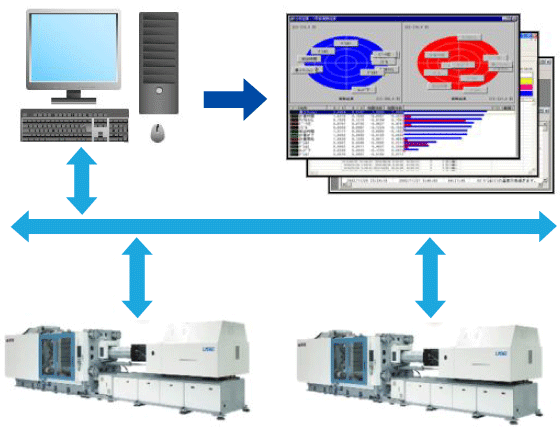

Injection molding machine

"LINKi", a quality information management system, has been adopted to meet the globalization of molding factories, and the system and services along "production control", "quality control", "preventive maintenance" and "remote maintenance" will contribute to the improvement of productivity.

2. Industrial DX Technology

-

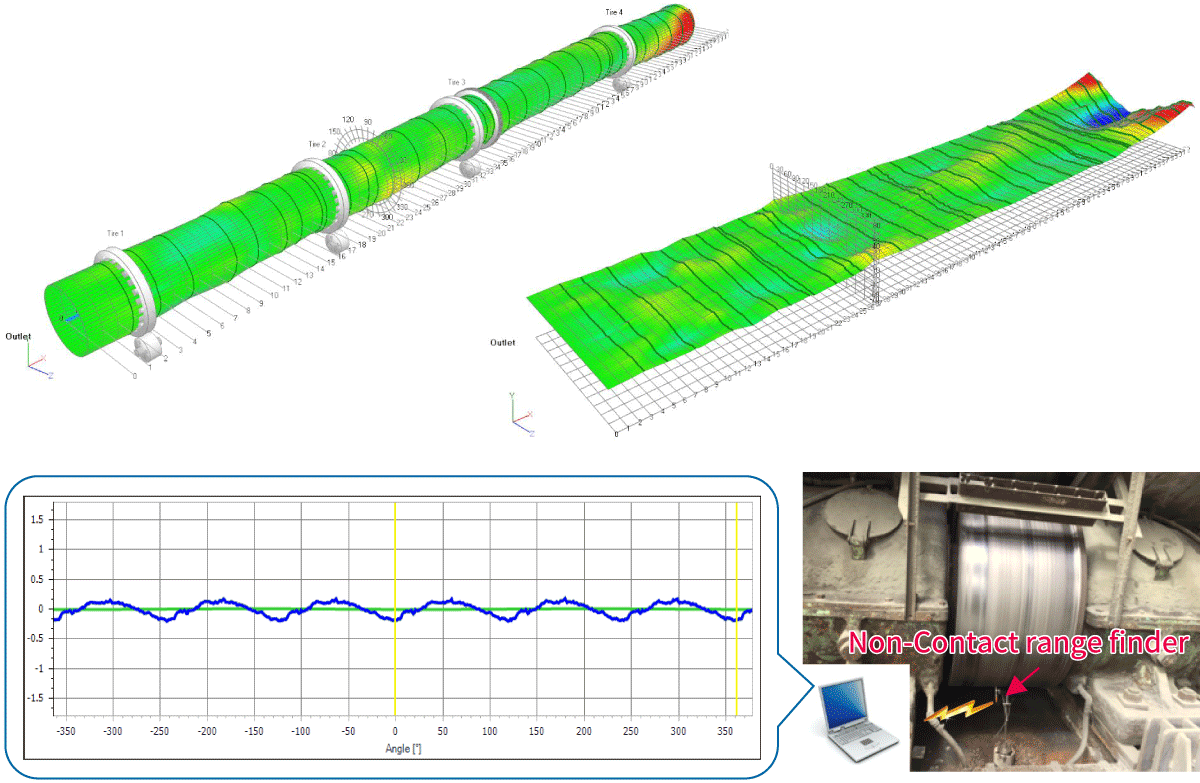

Kiln, Furnace & Dryer Business

Non-Contact Measurement Technology for KilnWe offer a wide range of diagnostic services that enable non-contact measurement of kiln conditions while the customer's equipment is in operation. We contribute customers through stable operation and preventing problems.

-

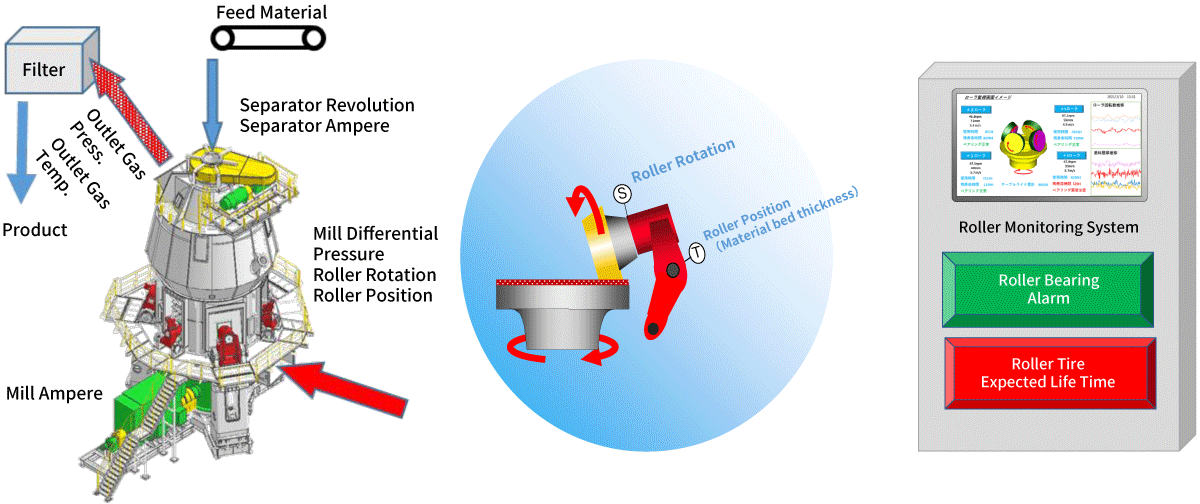

Mill System

Roller Monitoring SystemThe system contributes to stable operation of vertical mills by predicting the life of roller tires and detecting bearing abnormalities during operation.

-

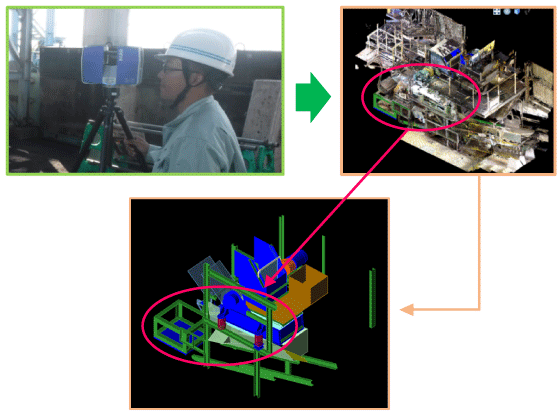

Crane & Bulk Handling Machinery Service

Equipment Improvement Technology through 3D UtilizationWe respond to requests for renewal of aging machinery and equipment. We can respond to requests from customers who are having trouble understanding the current status of existing equipment due to a lack of drawing data, etc.

-

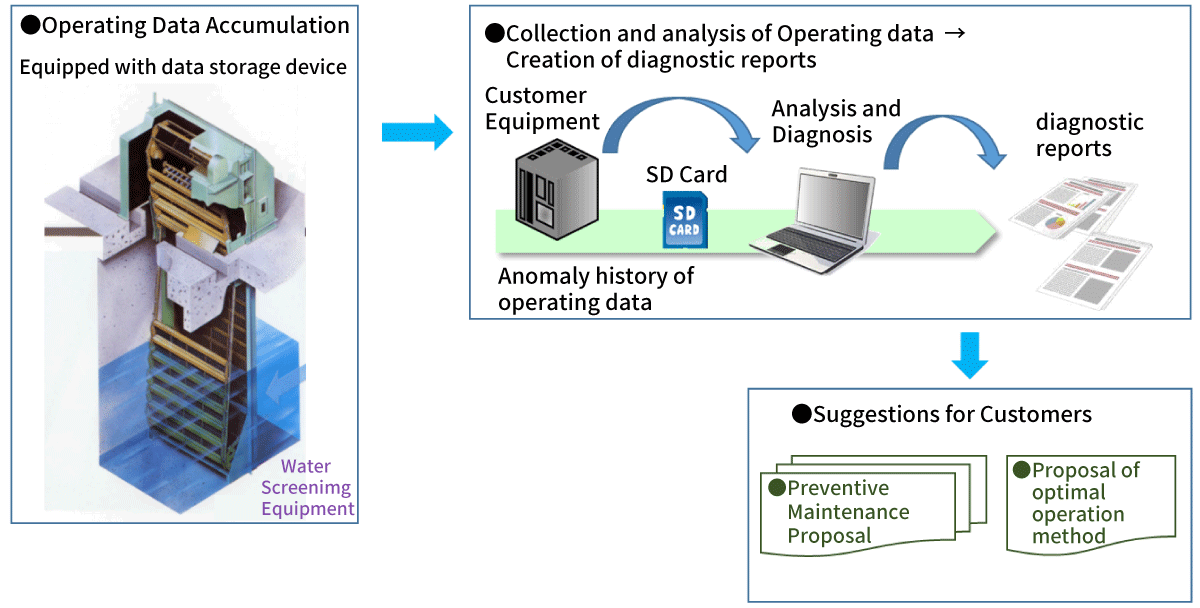

Water Screen

Operation Monitoring SystemWe accumulate operating data for each customer's operating facilities and propose equipment maintenance according to the operating conditions.We also make proposals for equipment improvements as needed.

-

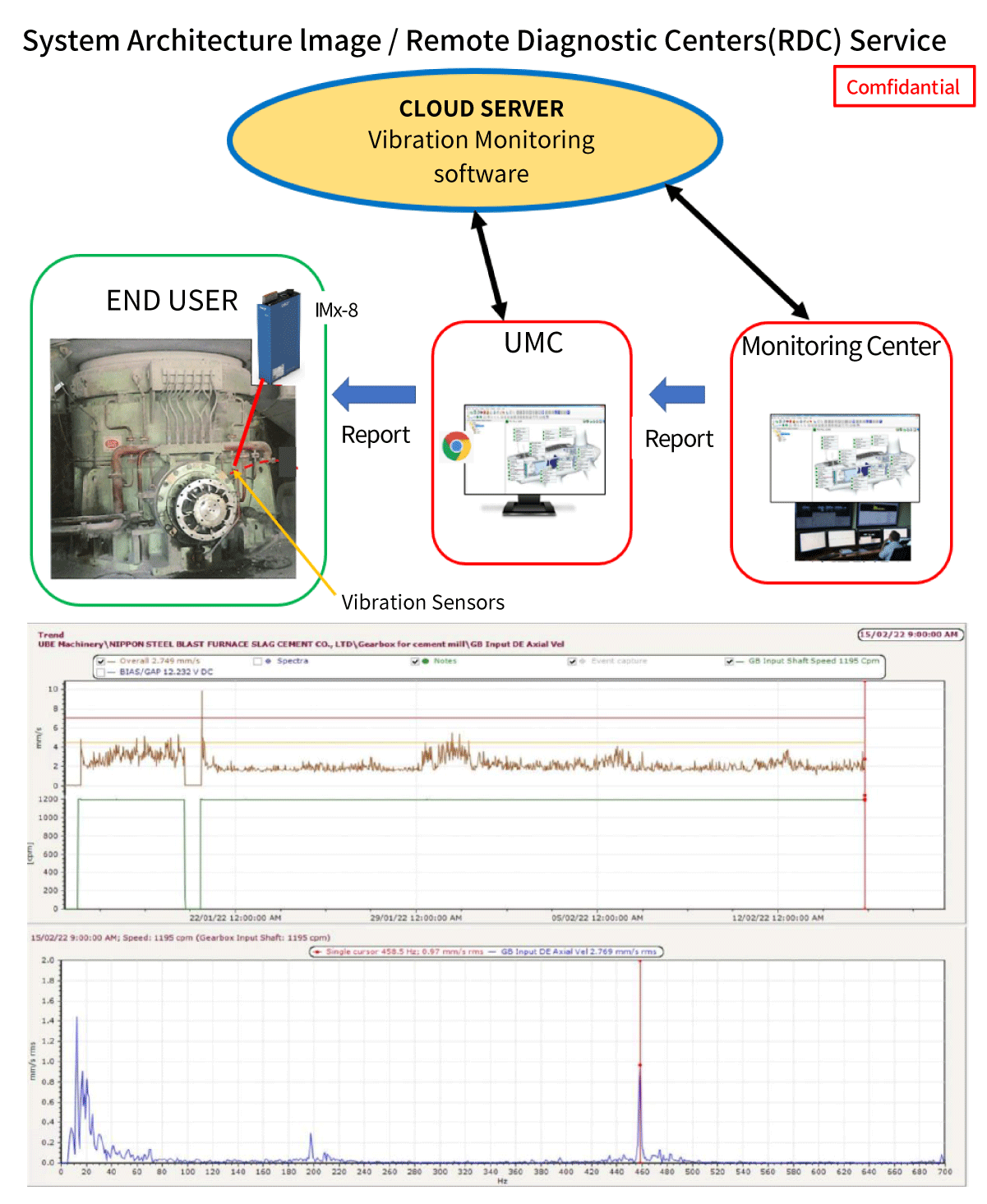

Reduction gear

Remote Condition Monitoring SystemBy introducing a condition monitoring system, vibration data, which is an indicator for diagnose of reduction gears, can be monitored remotely, contributing to early detection of abnormalities.

-

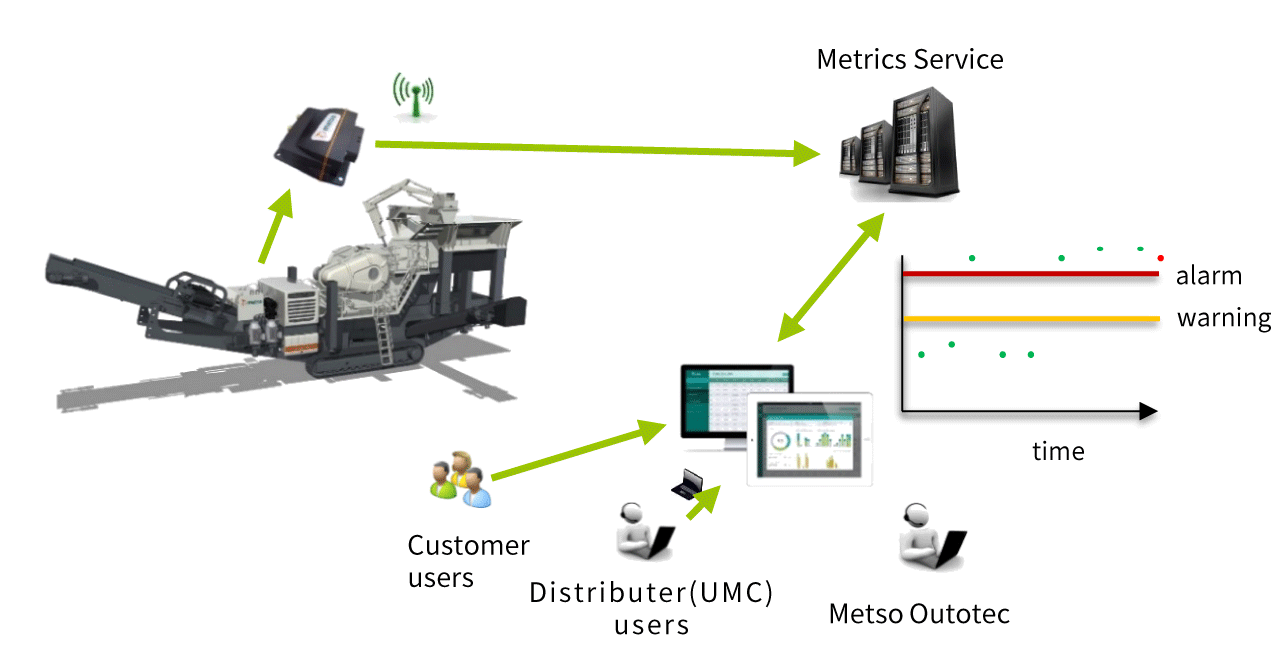

Crusher

Metric Service SystemMetso's metric system makes it possible to manage operations from remote locations. It also makes it possible to check the periodic maintenance schedule and contributes to preventive maintenance of facilities.

-

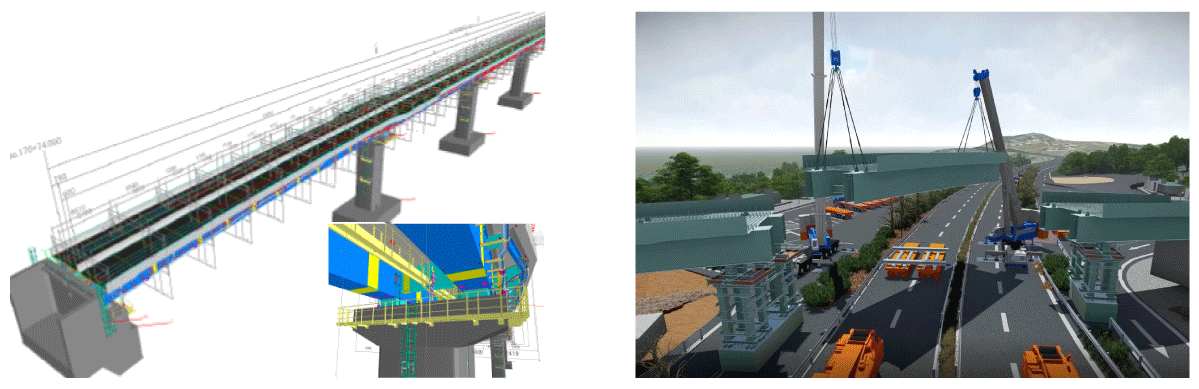

Bridge

Improving Construction Productivity through the Use of CIMUsing CIM/3D models, we will contribute to the improvement of construction productivity through design and fabrication studies and erection simulations to confirm construction and safety, and also by linking with AR/MR technology.

CIM (Construction Information Modeling)

3. Support for in-house productivity and business improvement

-

RPA (Robotic Process Automation)

Automate PC routine tasks to reduce working hours and concentrate resources on high value-added tasks. Software robots are created in each department, not only by specialized engineers, to improve work efficiency.

-

WF (workflow)

By digitizing business procedures, it is now possible to reduce document lead time, paperless, and telework with the Corona Disaster. In addition, it is now possible to reduce the number of office visits for stamping.

-

Digitization of inspection records

We are promoting paperless and improved work efficiency by digitizing inspection records. In addition, automatic data input from inspection equipment is being expanded sequentially to eliminate human error.

-

BI Tool Utilization

Various internal information is visualized and utilized to speed up recognition of issues and actions in each department and division.