IM Solution Center

Utilities to assist your business development (IM)

We provide multifunctional, high-performance machines that open up new molding possibilities "Dream and Future" that contribute to carbon neutrality.

1. Molding Trial Equipment

-

All electric toggle type injection molding machine

450HH-i25SAThis is the latest model of all-electric toggle injection molding machine that pursues "easy to use" and "stability" from the customer's viewpoint. UBE's proprietary "DIEPREST" technology, which achieves precise mold open/close control, meets a variety of molding needs including foam molding.

-

Electric 2-platen injection molding machine

1050em III-i80This latest model is the culmination of our pursuit of "compactness" and "high spec" since its world-first release in 1987, and meets customer needs with performance that makes the most of the features of the two-platen structure.

2. Solution Technology

-

Ultra-precision type open/close control

DIEPREST

AIRPRESTThe ultra-precise, multi-stage mold opening/closing control system provides high performance for a variety of high value-added molding, productivity improvement, and defect improvement.

-

Control tools for family molding

SCS MoldingContributes to "labor saving" and "energy saving" such as equipment minimization and reduction of mold costs in product concentration.

-

Plasticizing Technology

We offer plasticization specifications that maximize performance according to resin characteristics and molding environment using plasticization technologies including screw.

3. Injection Molding School

-

We offer injection molding training sessions that consist of classroom lectures and hands-on molding practice. We can also tailor the course content to meet your specific needs.

4. Injection Molding Support

-

Our molding technology experts, with extensive experience and achievements, will visit your factory and propose solutions to development issues and remedial measures for molding defects.

5. Fundamental Technologies Supporting R&D

-

Screw Technology

Our screw design, based on many years of research and development know-how and back data, enables highly accurate performance prediction for various requirements such as high-cycle molding, color dispersion performance, and special resins.

-

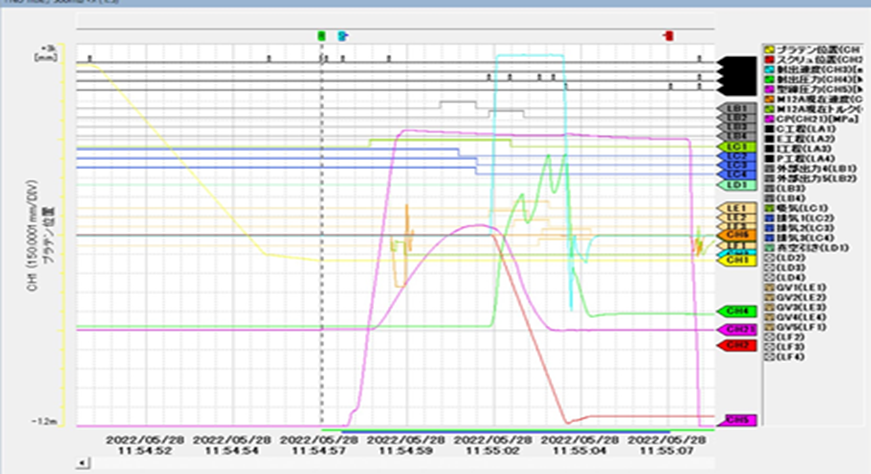

Molding Behavior Evaluation Technology

The evaluation method of molding phenomena using measuring instruments enables quantitative analysis to identify the causes of molding defects and to identify areas for improvement in productivity enhancement.