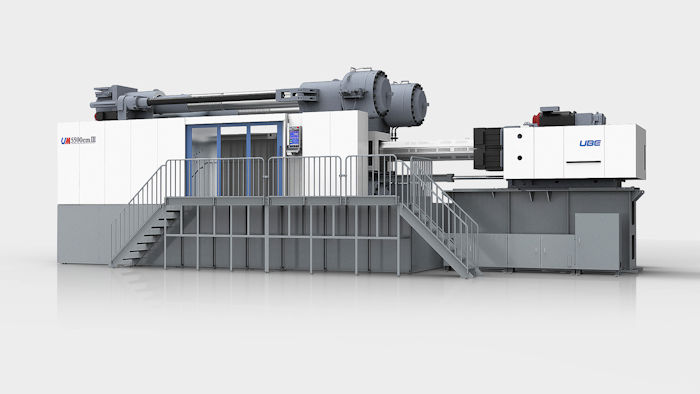

UBE Machinery Corporation Launches “5500emIII” — the World’s Largest Electric Injection Molding Machine

UBE Machinery Corporation, Ltd. (President: Hironori Miyauchi; Head Office: Ube City, Yamaguchi Prefecture; hereinafter, "UBE Machinery"), the core company of the UBE Group’s machinery business, has completed the design and development of the world’s largest electric injection molding machine, which has a clamping force of 5,500 metric tons, and will commence sales.

UBE Machinery has manufactured more than 100 large injection molding machines with clamping forces of 4,000 metric tons or greater. The company has also launched an ultra-large die casting machine for Giga Casting with a clamping force of 9,000 metric tons, earning high praise from customers around the world for its expertise in large-scale equipment. To meet the growing demand for larger plastic products, UBE Machinery has expanded its lineup by adding two new models in the ultra-large electric injection molding machines — the 5,500-metric-ton and 5,000-metric-ton models. The company has also fully redesigned and renewed the 3,500-metric-ton and 3,000-metric-ton models.

The “emIII” series, which now includes these four new models, traces its origin to UBE Machinery’s two-platen clamping injection molding machine, first launched in 1987 as the world’s first in kind. The series was electrified in 2001 with the introduction of the “em” series, and the current “emIII” represents its third generation. Equipped with the latest cutting-edge technologies, the “emIII” series has been highly acclaimed by customers in Japan and overseas. With this latest development, the lineup of the state-of-the-art “emIII” series has been significantly expanded to cover clamping forces ranging from 1,050 to 5,500 metric tons.

As the shift toward xEVs accelerates, growing demand for lightweight components is driving a rapid increase in the use of large resin parts — such as exterior body panels and aerodynamic underbody components. In response to these market changes, UBE Machinery has decided to introduce ultra-large all-electric machines to help enhance productivity not only in the automotive sector but also across a wide range of industries, including motorcycles, home appliances, industrial materials, and housing equipment. Looking ahead, the company will continue to expand its product lineup and pursue technological development that delivers both environmental performance and production efficiency, thereby supporting a sustainable future for manufacturing.

Main Specifications

- Clamping Force: 5,500 metric tons, 5,000 metric tons, 3,500 metric tons, or 3,000 metric tons

- Theoretical Injection Volume: 31,400 cm³ (equivalent to 26.5 kg when using polypropylene [PP]), 13,200 cm³ (equivalent to 11.2 kg when using PP)

Features of “emIII” Series

- 1. Energy-saving performance contributing to carbon neutrality, and reduced environmental impact through the use of water-soluble paints

Power consumption has been reduced by more than 20% compared with UBE Machinery’s previous electric molding machines. Improved holding-pressure performance extends pump stop time, which in turn reduces the consumption of hydraulic oil and grease — helping to lower running costs and cut CO2 emissions. Additionally, environmentally friendly water-soluble paints have been adopted to help suppress the emissions of volatile organic compounds (VOCs). - 2. Industry-leading dry cycle time

Mold release is driven by ball screws for mold opening and closing, shortening the dry cycle by 30% compared with the company’s previous electric molding machines and achieving industry-leading speed. This enables high-cycle molding for increased productivity. - 3. Compact machine length

As a two-platen machine known for its compact footprint, the new model further reduces overall machine length compared with the previous “emII” series. It ranks among the most compact in the industry, making it easier to secure installation space and allowing greater flexibility in factory layout planning. (For reference, the 5500emIII model has an overall length of 16 meters.) - 4. High-precision parallelism control of mold opening and closing

The mechanisms for mold opening and closing, driven by electric servo motors, are positioned diagonally on the platen. By precisely synchronizing these servo motors, the system maintains mold parallelism at all times during opening and closing operations. As a result, uneven wear and damage are prevented, contributing to longer mold life and improved accuracy of molded products. - 5. Automatic measurement of platen parallelism

With the press of a single button, the system automatically checks platen parallelism, supporting equipment condition monitoring and management. - 6. Molding technologies developed over many years of experience

A wide range of optional features is available, including dedicated screws for long fiber reinforced thermoplastics (LFT), foam core-back molding systems, and other options that have earned strong recognition from customers.

| ■UBE Machinery Profile | |

|---|---|

| Name : | UBE Machinery Corporation, Ltd. |

| Location : | 1980, Okinoyama, Kogushi, Ube City, Yamaguchi Prefecture |

| Representative : | Hironori Miyauchi, Representative Director & President |

| Business Description : | Manufacture, sale, service, and maintenance of die casting machines, extrusion presses, injection molding machines, kilns, chemical equipment, crushers, vertical mills, bulk handling machines, water screening equipment, bridges, floodgates, steel structures and other industrial machinery |

| Capital : | 6,700 million yen |

| Founded : | January 1914 |

| Established : | September 1999 |

| Shareholder : | UBE Corporation (100%) |

| Number of Employees : | 1,200 (As of October 1, 2025) |

Contact

- UBE MACHINERY CORPORATION,Ltd.

- General Affairs Group

General Affairs Department. - Tel: +81-(0)836-22-6465

- Injection Molding Machine Sales Department

- Tel: +81-(0)3-5419-6212

- Contact us by email

- Email Inquiry Form