HFC Series(M/L)

Hybrid fill casting

HFC Series (M/L)

Hybrid fill casting

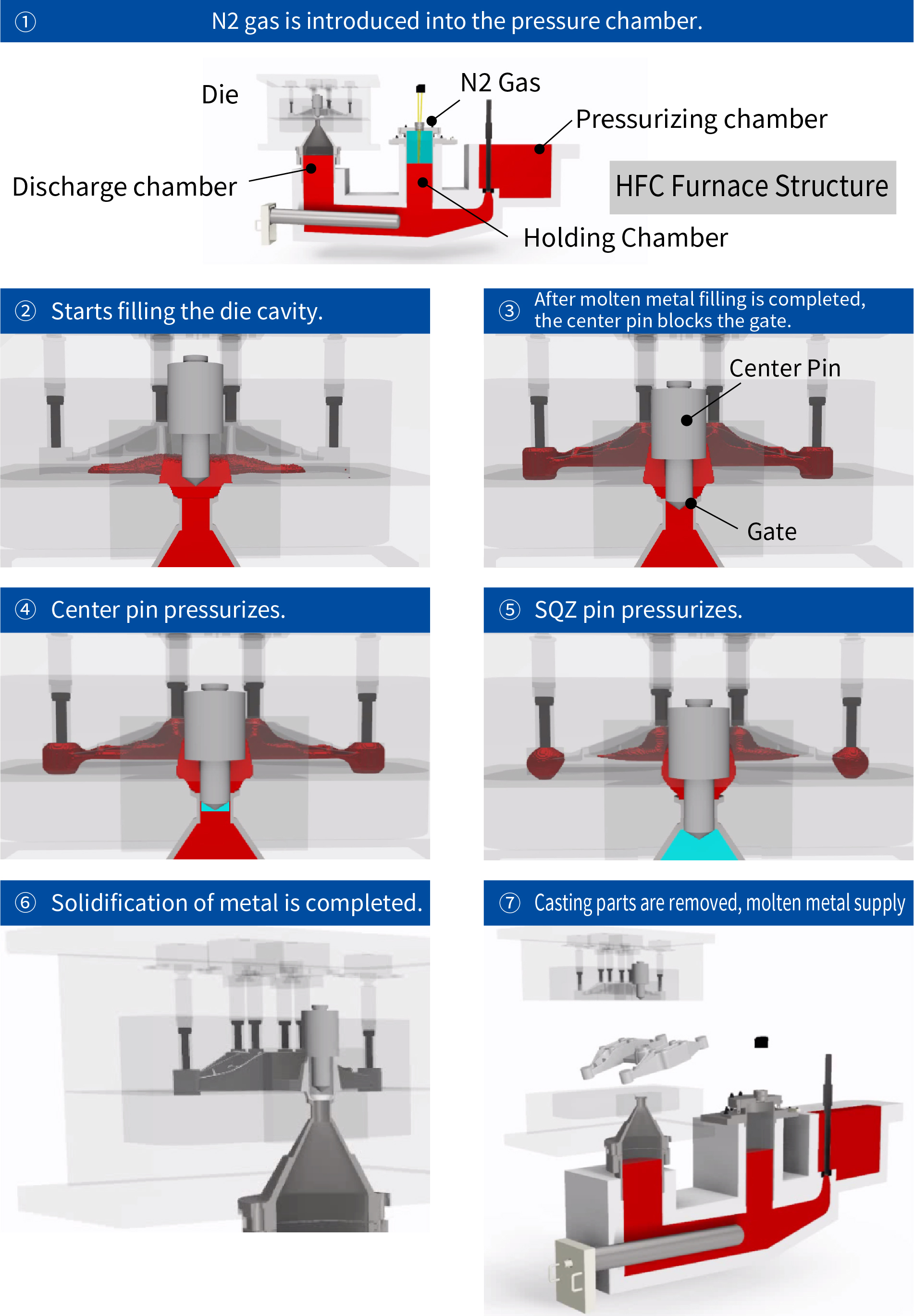

The Hybrid Fill Casting series combines molten metal filling with N2 gas and hydraulic pressure solidification. This space-saving, energy-saving die casting machine can produce high-quality, high-strength products through a unique casting process that can suppress the buildup of oxides in the molten metal.

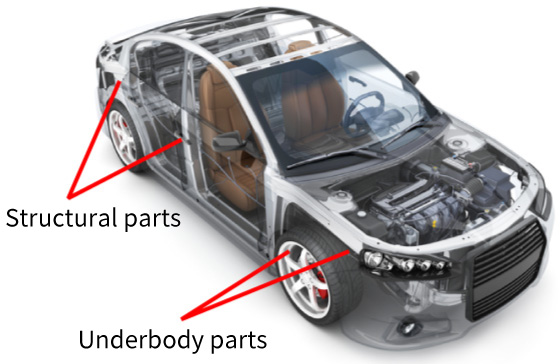

Our approach to automotive body parts, EV parts, and thick-wall strength parts.

| Automotive Parts | The trend | Our efforts |

|---|---|---|

| Structural Parts | Increasingly multi-material | Aluminum is converted into aluminum by die casting and extrusion press, and resin to plastic by injection molding. |

| EV Parts | Distributed in different processes due to its pioneering stage. (Die casting, extrusion press, low pressure casting) |

Die casting of mechanical and electrical integrated parts, die casting of inverter housing, die casting of battery housing (extrusion press) |

| Thick wall strength parts | Increasing shift to aluminum with significant weight reduction impact (HPDC, LPDC, a variety of die casting processes, forging) |

Aiming to replace conventional processes with HFC. |

Weight ratio of each part to vehicle weight

| Vehicle Parts | Weight ratio |

|---|---|

| Structural parts | 44% |

| Underbody parts | 22% |

| Powertrain parts | 25% |

| Electrical parts, etc. | 9% |

Thick-wall strength parts are still needed for EVs and commercial vehicles.

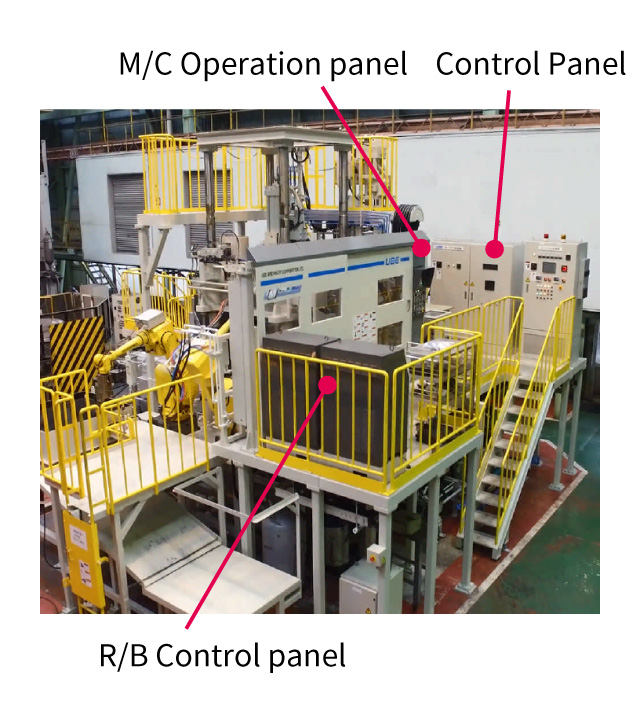

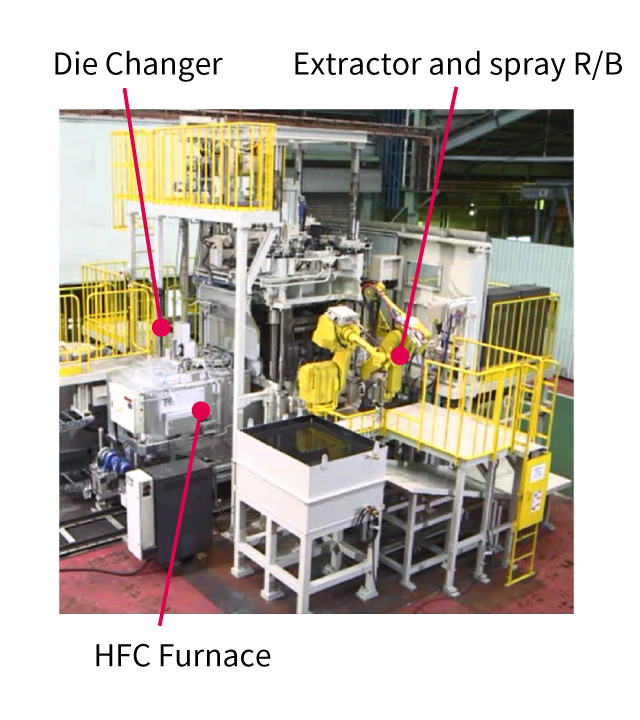

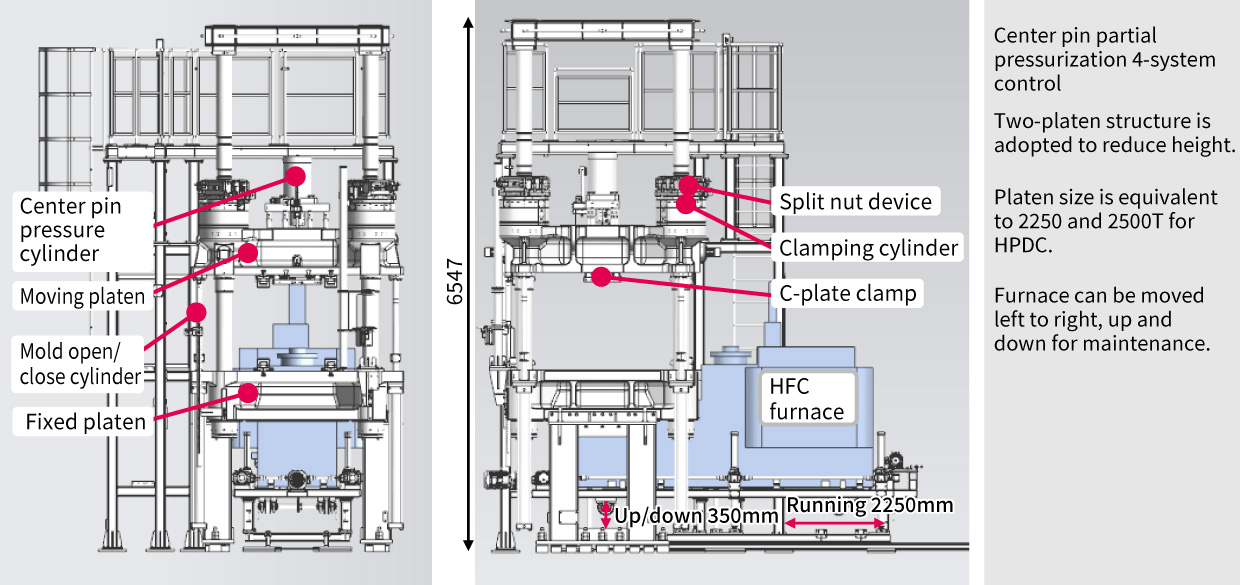

HFC System Outline

Casting equipment/L-HFC (Structure, Main Specifications)

| Items | Specification |

|---|---|

| Die Clamping force (ton) | 750 |

| Die thickness (mm) | 1100~1200 |

| Read between tie bars (mm) | 1720/1620 |

| Center pin output (ton) | 60 |

| Items | Specification |

|---|---|

| Center pin stroke (mm) | 100(350) |

| Maximum Casting Weight (kg) | 45 |

| Continuous casting weight (kg) | 800 |

| Three-phase induction motor (kW) | 55 |

Process Description

Filling process adopt [Hybrid] Air and hydraulic power. Hybrid Fill Casting