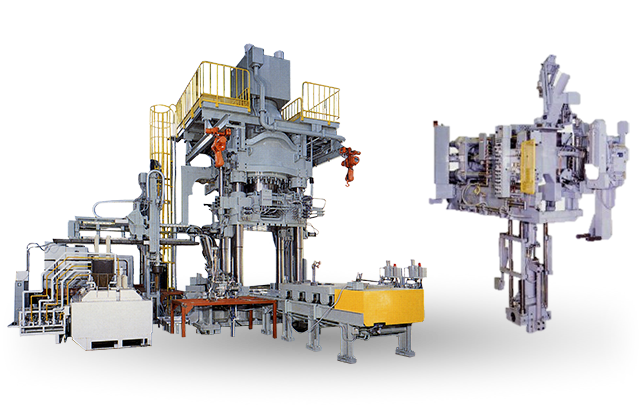

HVSC Series

(Die clamping force: 350 ~ 1200 ton)

VSC Series

(Die clamping force: 200 ~ 800 ton)

Squeeze Casting Machines

HVSC Series / VSC Series

Squeeze Casting Machines

Products produced by squeeze casting machines can be welded because they contain less gas than conventional die cast products, and high quality products similar to forged products can be produced at a stable good rate. Two series are available: VSC with vertical die locking and vertical shot, and HVSC with horizontal die locking and vertical shot.

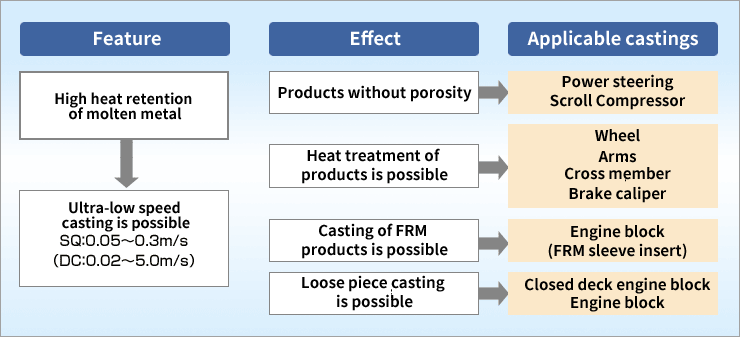

Squeeze Casting Machines Features

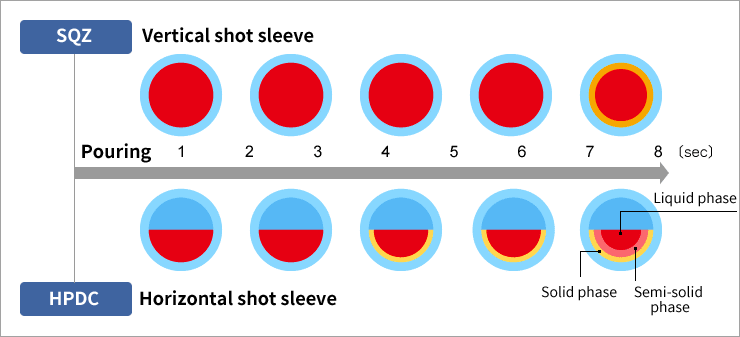

Molten metal temperature distribution in sleeve

Features of the HVSC Series

Horizontal mold clamping and vertical casting mechanism

The same horizontal toggle mold clamping and shot mechanism is designed to work from bottom to top, which is the most excellent system for heat retention of molten metal and elimination of air.

Inclined Docking Injection Mechanism

Our unique tilting docking mechanism minimizes the time from pouring to casting, maintains molten metal temperature, and enables ultra-low-speed shot.

Choice of shot unit mechanism

A pitless type that does not require a pit for shot unit is also available.

Features of the VSC Series

Vertical mold clamping and vertical shot unit mechanism

This mechanism works from top to bottom for die locking and from bottom to top for shot. This is the most excellent method for keeping molten metal warm and eliminating air entrapment.

Inclined Docking Injection Mechanism

Our unique tilting docking mechanism minimizes the time from pouring to casting, maintains molten metal temperature, and enables ultra-low-speed shot.

Two-Stage Clamp Control System

Die locking force is switched from low to high during injection to facilitate degassing inside the die.