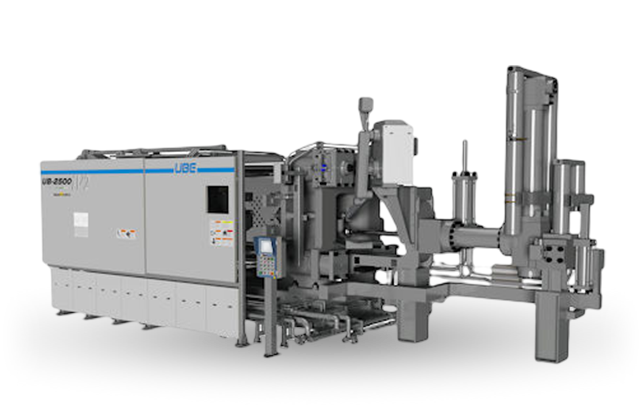

UB-iV2 series

Large Size Die Casting Machine

(Die clamping force : 1650 ~ 6500 ton)

UB-iV2 series/Large Size Die Casting Machine

Taking over the energy-saving servo pump "I-Stop-Servo" and our one of a kind technology "HS-DDV" electric servo valve for ultra high-speed injection from the UB-iV series, additional new features are available. In addition, iV2 covers much larger clamping forces than iV to meet the demands of Giga Cast products.

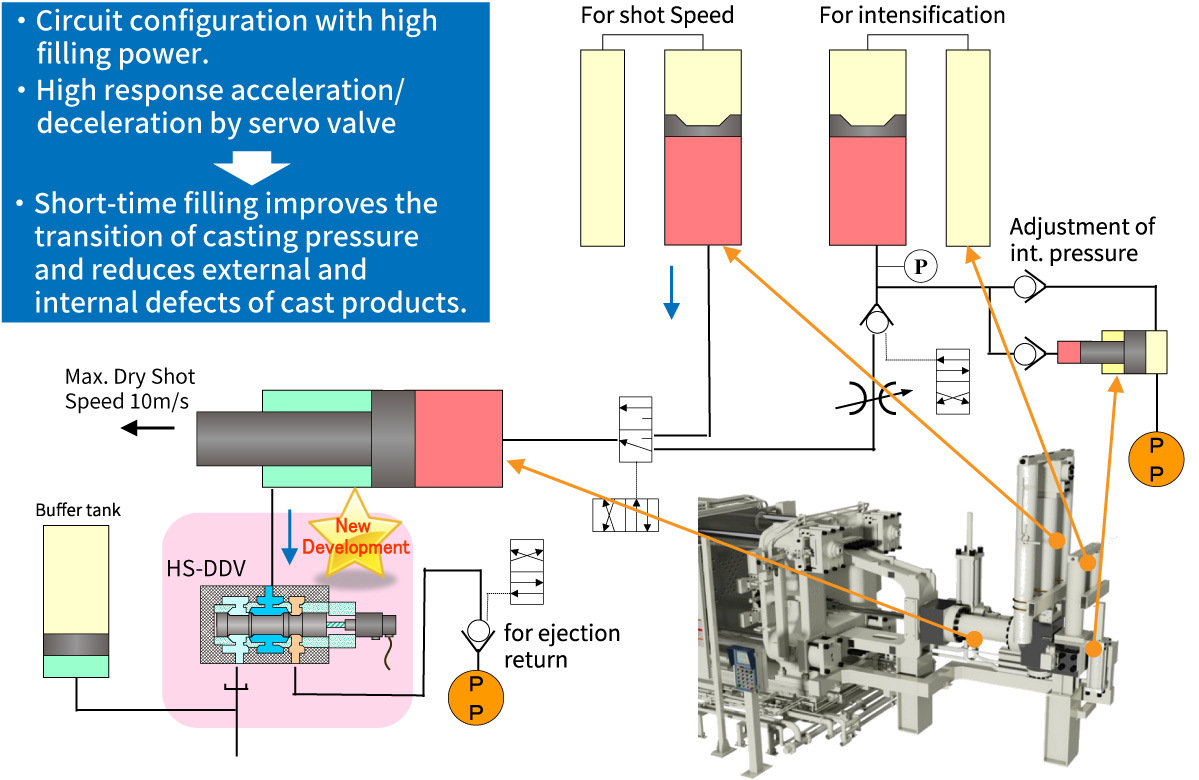

High-power and ultra-high-speed shot unit

Brush up on the proven circuit configuration of the UB-H Series.

The newly developed electric servo valve HS-DDV is also equipped.

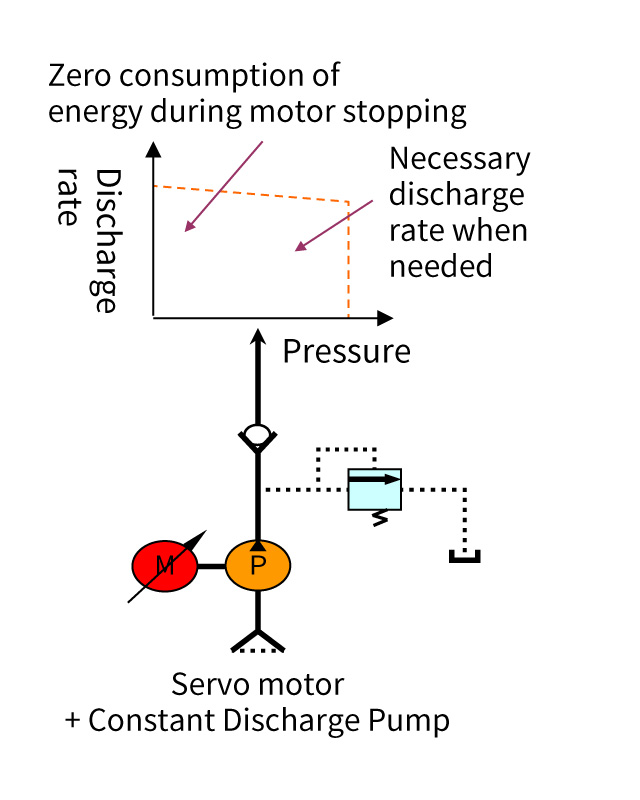

Energy Saving Servo Pump : "I-Stop Servo"

First in its class!

Energy saving servo pump with "Idling Stop" & "rotational speed control" features as standard and achieves significant energy saving.

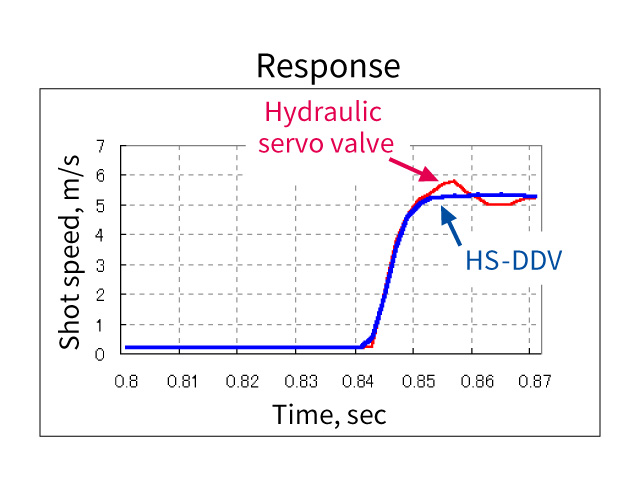

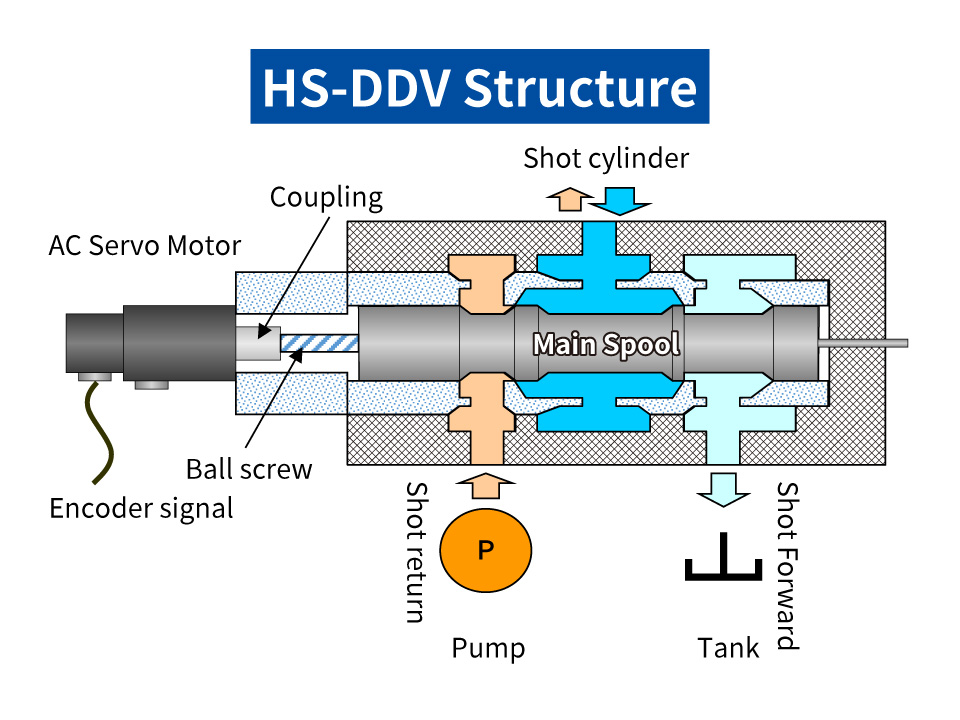

Electric Servo Valve : Advantages of HS-DDV

Electric Servo valve

Direct spool control by Electric Servo valve via ball screw

⇒Substantial improvement of contamination resistance

⇒Simple structure leads to maintenance free

No pilot pressure

No pilot line pump unit required

⇒Energy Saving

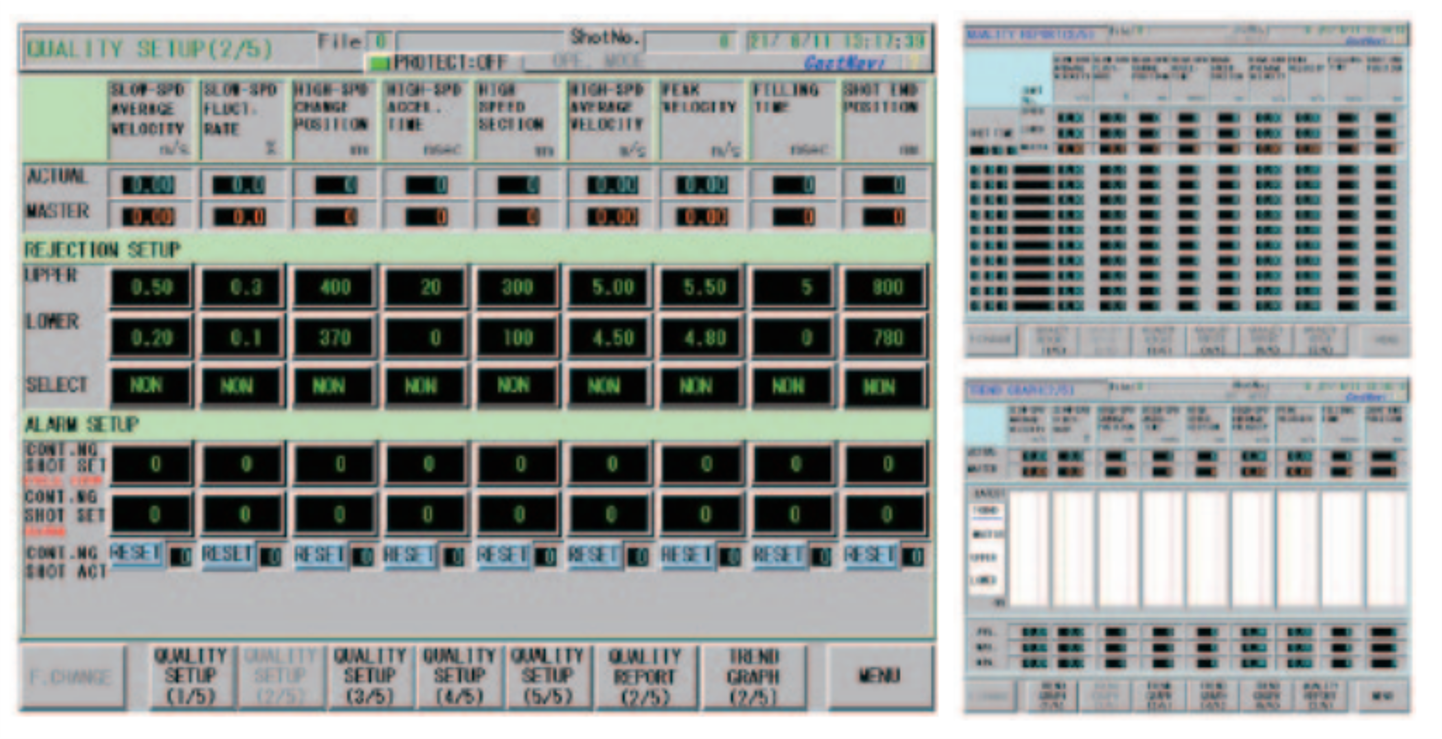

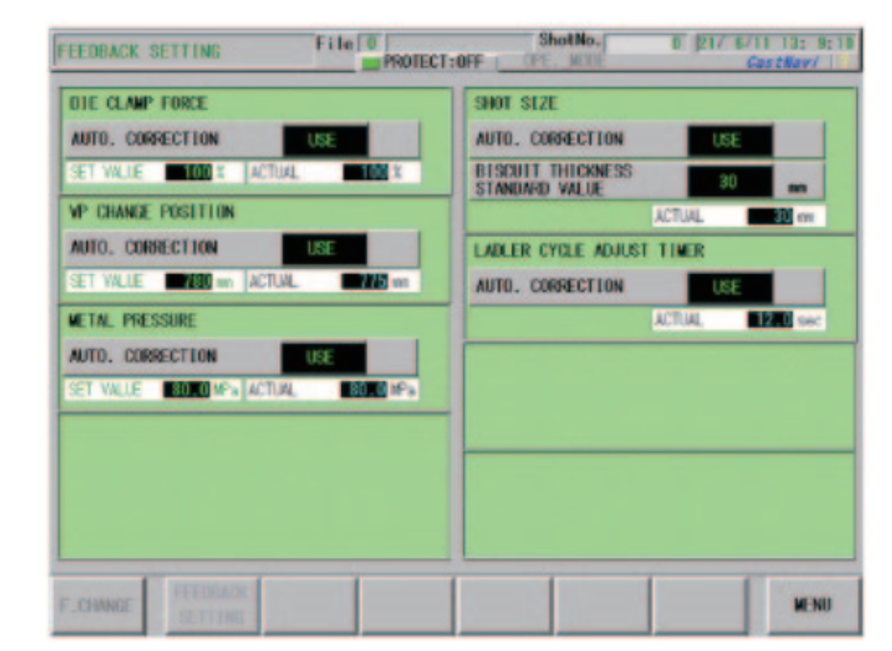

Human machine interface : CastNavi

Enhanced Feedback Control

As a standard feature, Clamping force, VP change position, metal pressure, shot volume*, and ladler cycle time adjustment timer* are available for cycle time feedback control. Actual value measurement of each data is not required with this feature.

*Shot volume and ladler cycle adjustment timer correspond only to UBE standard ladler.

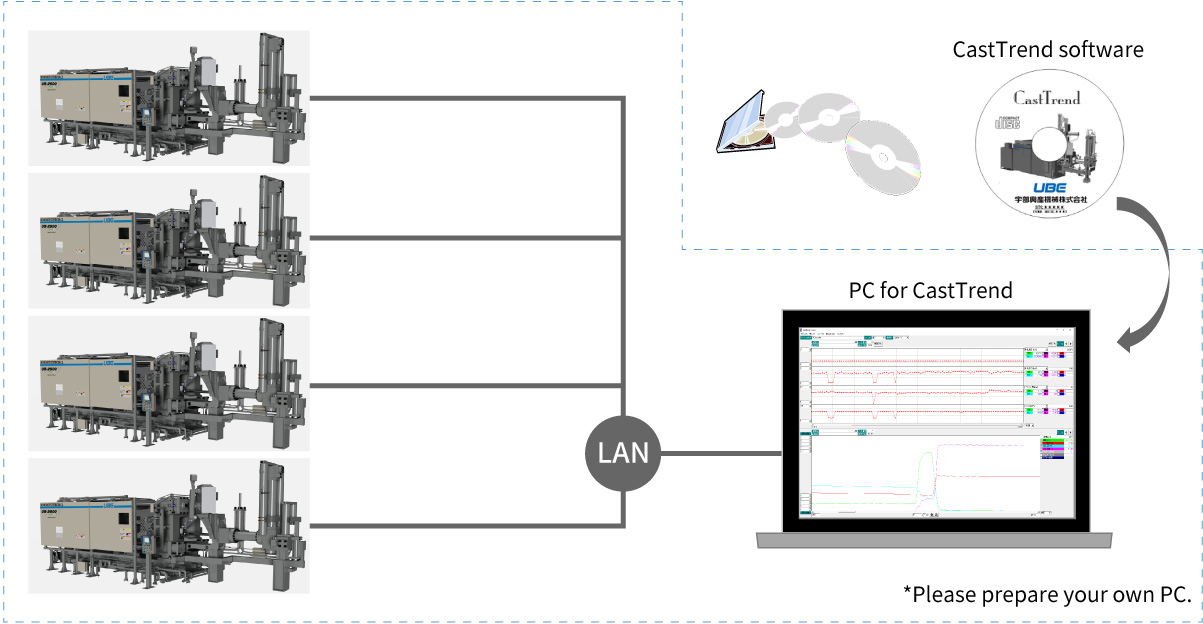

CastTrend (standard feature)

CastTrend software (casting data collection and data viewer) and the dedicated LAN port for connection are available as standard features of iV2. Casting data collection and management system can be easily set up with only a PC and LAN cable preparation.

Multiple machine control from a PC or laptop computer is available through a single network connection. Connection through your Intranet and server is also available. (Optional)