UBE Machinery's Injection molding

“Controlling the air"

Mold gas venting Injection molding

- AIRPREST -

AIRPREST

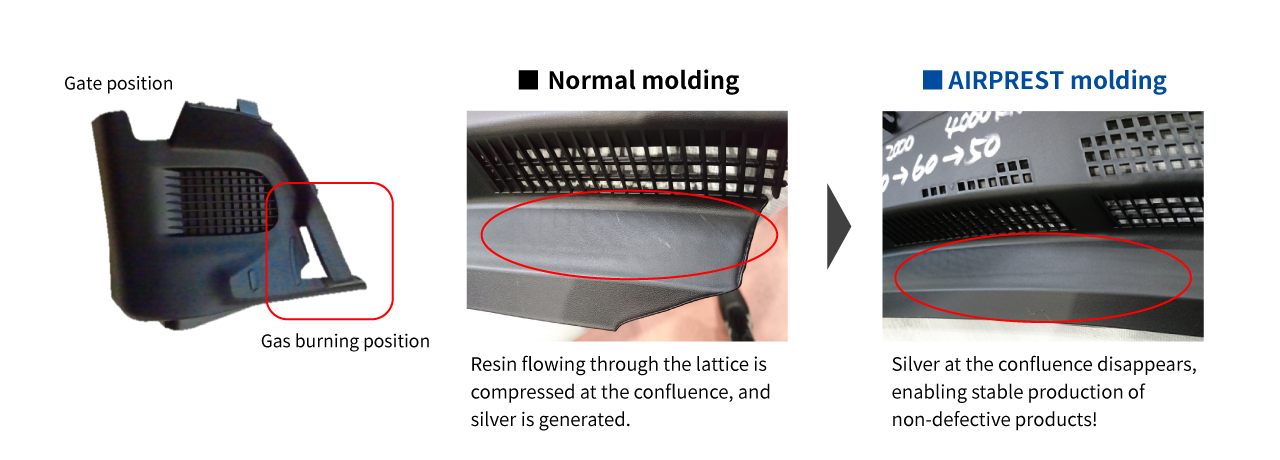

Gases generated during molding are a major cause of various molding defects such as gas burns.

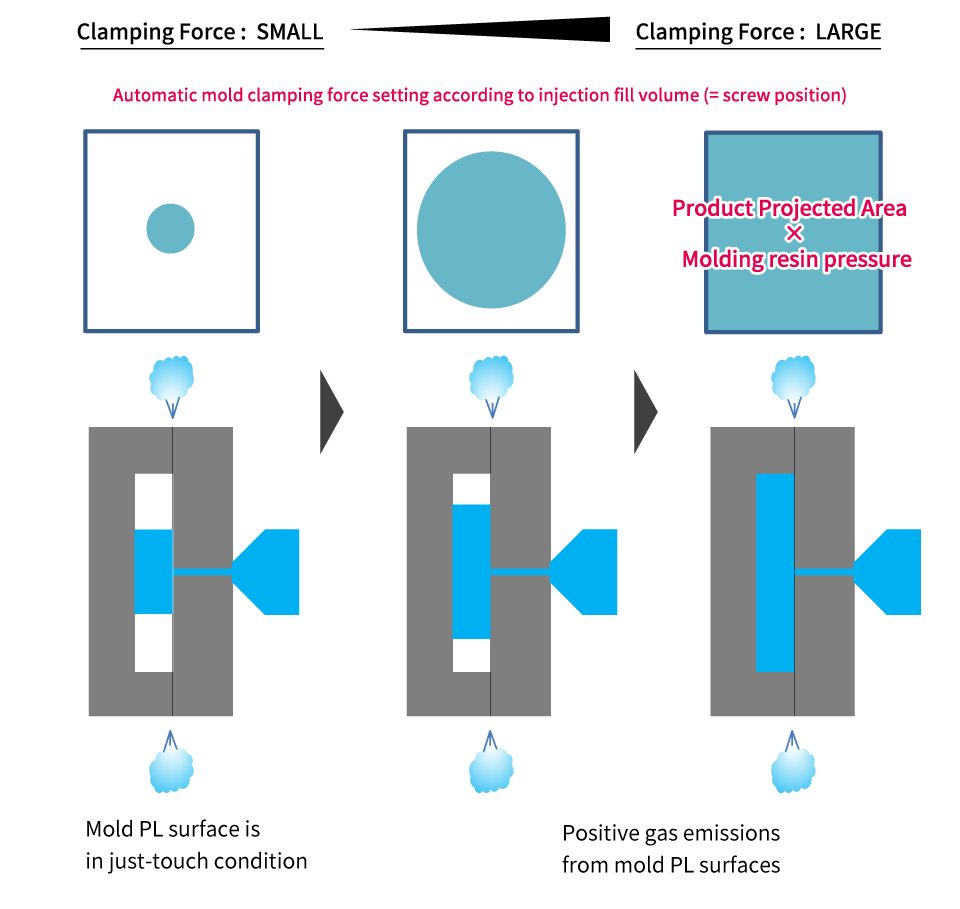

UBE's unique ultra-precision mold open/close control "AIRPREST" is effective in improving molding defects and cooling efficiency at flow ends and weld areas by degassing gas in the cavity from the mold PL surface by changing the mold clamping force in multiple steps according to the required mold clamping force, which varies according to injection filling conditions.

The same ultra-precise mold open/close control algorithm as DIEPREST achieves high precision and high repeatability.

AIRPREST: UBE Machinery's registered trademark in Japan

UBE's unique free mold clamping control allows for proper control of air in the mold.

Optimal mold clamping according to injection filling and optimal mold clamping cooling retention suitable for the mold can be set.

Clamping force setting: Injection filling area × molding resin pressure

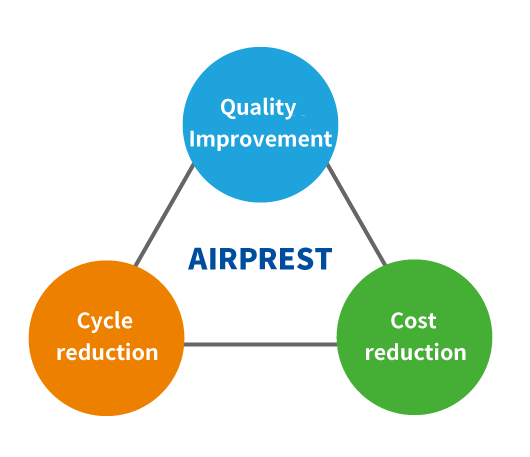

Examples of Expected Effects

- Improved molding quality

- Cost reduction

- Shorter molding cycle

- Reduction of mold maintenance

Examples of AIRPREST Effects

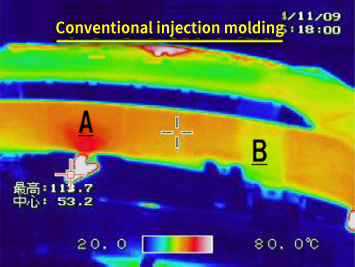

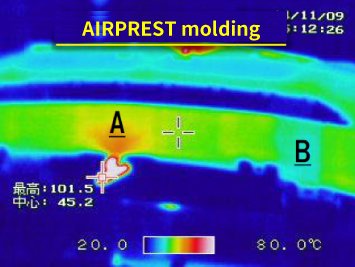

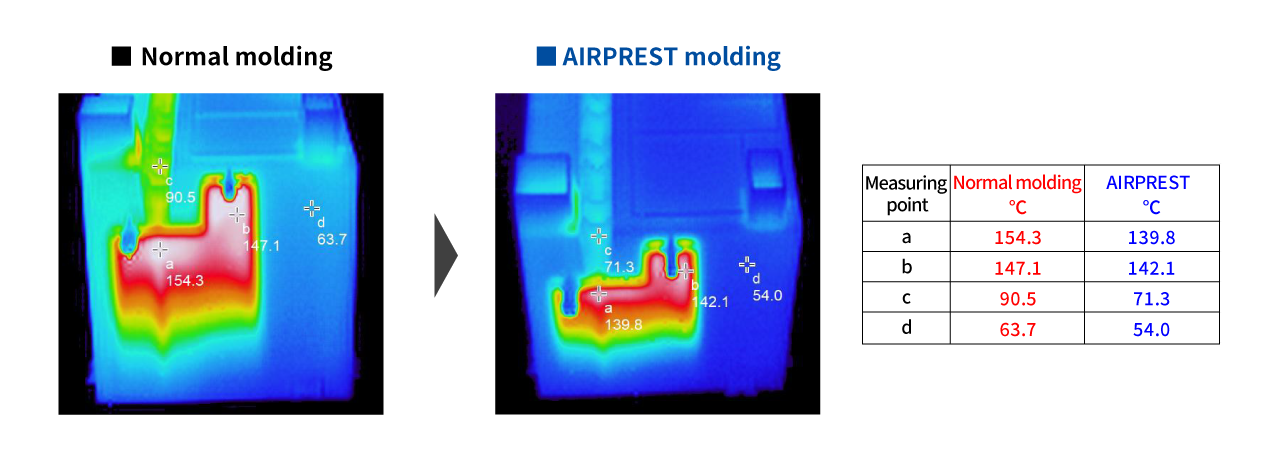

Lowering and equalization of product surface temperature

Ultra-precise mold clamping force control by AIRPREST accelerates gas venting in the mold cavity and is effective in lowering and equalizing the product surface temperature.

It shortens cooling time, reduces product deformation to reduce defect rates, facilitates post-processing, and reduces mold clamping force.