UBE Machinery's Injection Molding

Easy-to-operate "Connected" controller

UBE Machinery's unique control algorithm, based on our injection molding machine manufacturing technology, and the control speed corresponding to the high-response speed due to electric drive, enables complex controls such as motor synchronous control and DIEPREST.

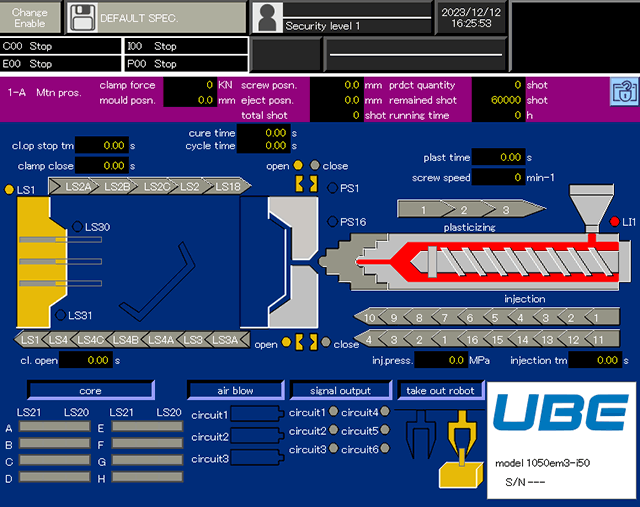

MAC-IX (HH, em, MMX series)

MAC-IX is a more advanced "connected" controller.

Next generation architecture centralized controller. It is easy to operate with two independent monitors and a swivel mechanism, and is capable of high-speed, high-precision control through EtherCAT® high-speed communication, and IoT solution such as factory monitoring, operation records, alarm history, quality control, and quality analysis.

EtherCAT® is a registered trademark of Beckhoff Automation GmbH.

- Exceptional operability with two screens combined on one large screen.

- An upgraded security function that utilizes ID card authentication is equipped as standard.

- Stable molding by high-speed control that is six times faster than a conventional system.

Upgraded operability

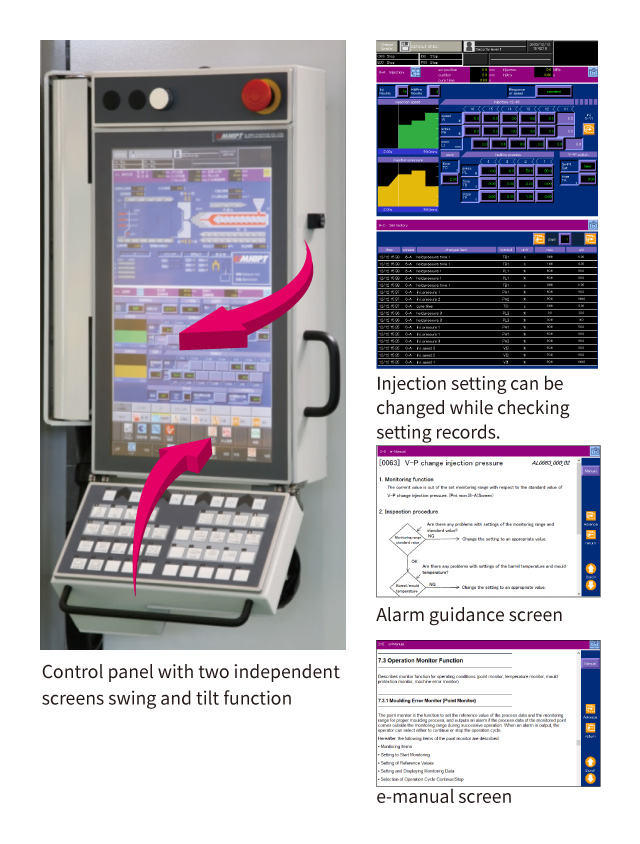

Swing and tilt mechanism

Easier operation with control panel swing and tilt.Injection waveform memory

An ideal process, waveform can be saved and displayed on-screen for checking shot-to-shot repeatability.

This feature helps ensure consistent production.Vertically long screen

Long, vertical screens can display twice the trend data compared to a conventional system.

High-speed, high-accuracy control

Reduced scan time

Scan time is shortened to 1/6 of a conventional system by using EtherCAT® High-speed communication which provides for stable weight of the molded product.

Upgraded security function

Security ID card system

Login by ID card which can be assigned to an operator; automatic change of languages and units.

Prevention of password loss.Traceability management

Operator's information is added to the operational/setting records.Control over operator access

Capable of setting 4 levels of access for each operator.

User support function

Alarm guidance

Actions for alarm resolution by using a flow chart which can be restored easily. Easy identification of faults by improved alarm messages.e-manual

The machine manual can be reviewed on screen.Screenshot

Screenshot data can be saved to USB for ease of printing documents.Automatic mold setup memory

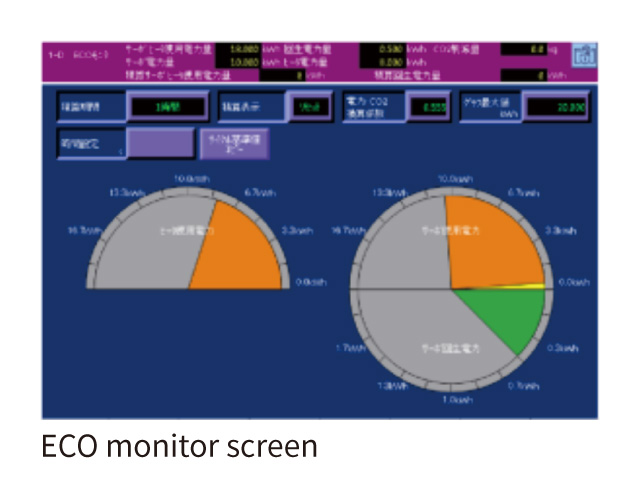

Mold setup data can be saved to internal memory (480 molds) and external memory (1008 molds).ECO monitor

Displays power consumption of servo motors and heater, and support management.

Global reliability

An uninterruptable power supply(UPS) is standard equipment

Prevents trouble resulting from voltage drops or brownouts, even in areas with unstable electric power supply. Data can be safely backed-up in case of a power outage.A surge suppressor is standard equipment

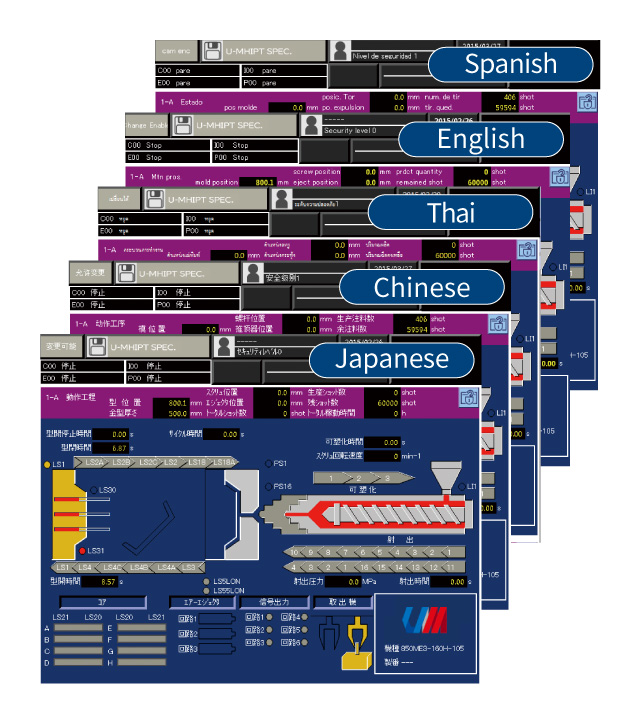

Protect the control system from lightening strikes.Multi-language selection

Standard languages available are Japanese, English, Chinese, Spanish and Thai (new addition). Eight other languages are available as an option. A maximum of three languages is selectable from a total of 13 languages.Pictographic switches (ISO-compliant)

Easy to operate by pictographic switches.Variety of international standard compliances

Complies with JIMS, ANSI, EN, GB and KCS standards. Will comply with ISO20430 soon.IEC 61131-3-compliant ladder

The operation sequence is created by global standard ladder language.

MAC IX configuration (Image)

High-speed communication bus system EhterCAT®

Reduces communication variability between devices.

No multiple control devices, so control can be performed without delays or variations.Easier maintenance of hardware components

No need to update control devices for each device; integrated control devices can be supplied with upwardly compatible control devices for a long period of time.

“SHOT-LINK i 2”

Product and quality information management system for globalization of molding facilities

(Note) "SHOT-LINK i 2" is a production and quality information management software for injection molding machines developed and provided by FANUC Corporation. SHOT-LINK i 2" is to be used in combination with software provided by UBE Machinery Corporation, Ltd.

e-HUMMA (UF series)

Simple operation controller:

e-HUMMA

The "e-HUMMA" control unit realizes both high functionality and high performance of electric injection molding machines and user-friendliness in terms of operability and visibility with the keyword "user-friendly". No need to adjust detailed parameters, and easy setup and operation that does not rely on experience or intuition, anyone can easily realize highly responsive and highly accurate injection control.

[Compact operation panel]

The fusion of a large color LCD touch panel, pictorial membrane sheet, and hard switches has realized improved operability, visibility, and safety.

[Intuitive one-shot icon]

The intuitive one-shot icon is used to instantly open the screen you want to see.

[Control system]

The control system has a high degree of freedom and expandability, allowing for easy system modification and addition of options.

[CAE analysis software: Mold-Link linkage]

*Mold-Link and hardware for Mold-Link operation are optional.

Seamless linkage of molding data between UF series and UIS CAE link system: Mold-Link is possible using a dedicated format.