UBE Machinery's Injection Molding

“Ultra-precise mold open/close control” - DIEPREST -

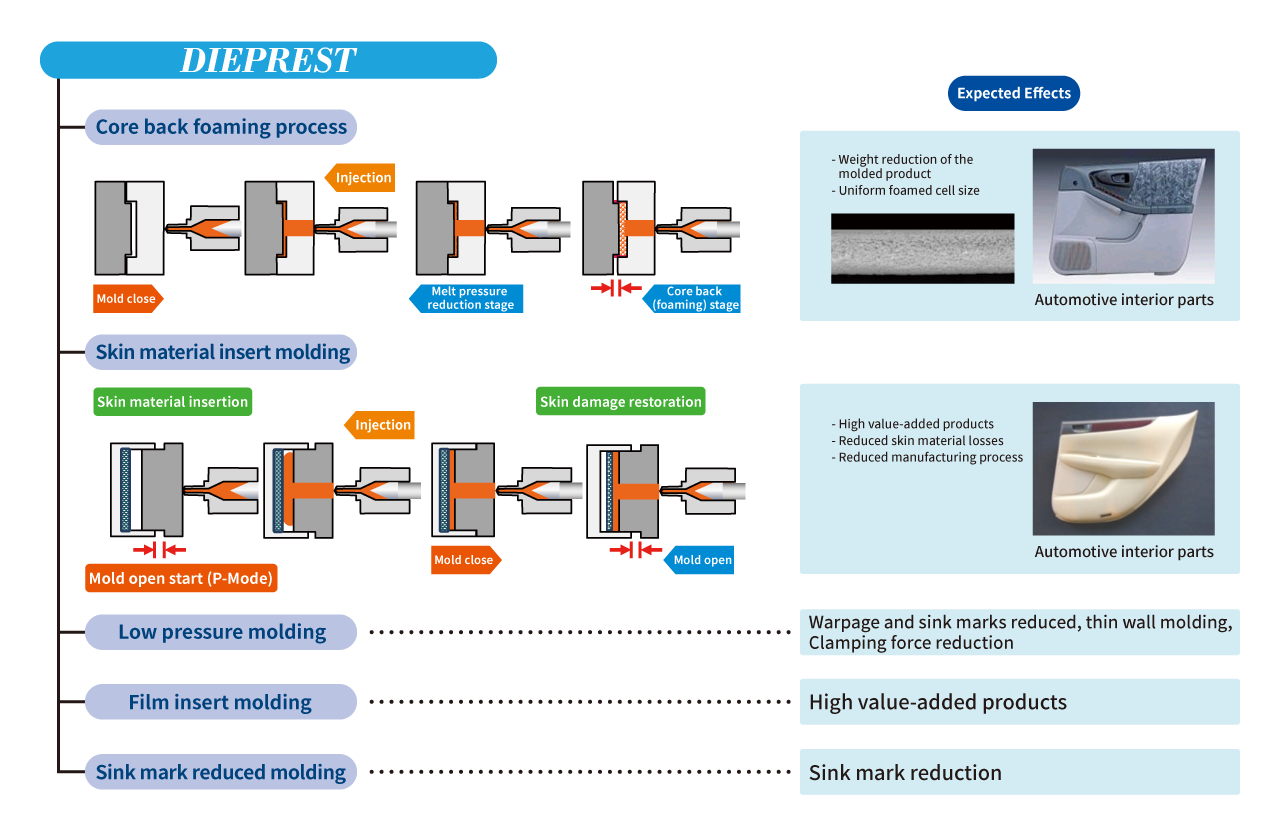

DIEPREST is a multi-purpose, high-function, ultra-precision mold open/close control system that can be used for a wide range of applications, including core-back foaming process to reduce the weight of plastic products such as automotive interior parts and achieve uniformly fine foaming, skin material insert molding, and defect countermeasures such as warpage reduction.

DIEPREST is a proprietary technology developed based on UBE Machinery's extensive molding know-how accumulated over many years. DIEPREST enables a variety of special and high value-added molding processes, including core back foaming process, and provides high quality molded products.

DIEPREST: Registered trademark of UBE Machinery in Japan

Multi-stage mold open/close operation mode for a variety of special molding

Examples of Molded Products (Skin material insert molding)

| Mode: | DIEPREST-P-Mode |

|---|---|

| Core Material: | PP |

| Skin Material: | TPO/PP foam |

| Product: | Front Door trim (Automotive) |

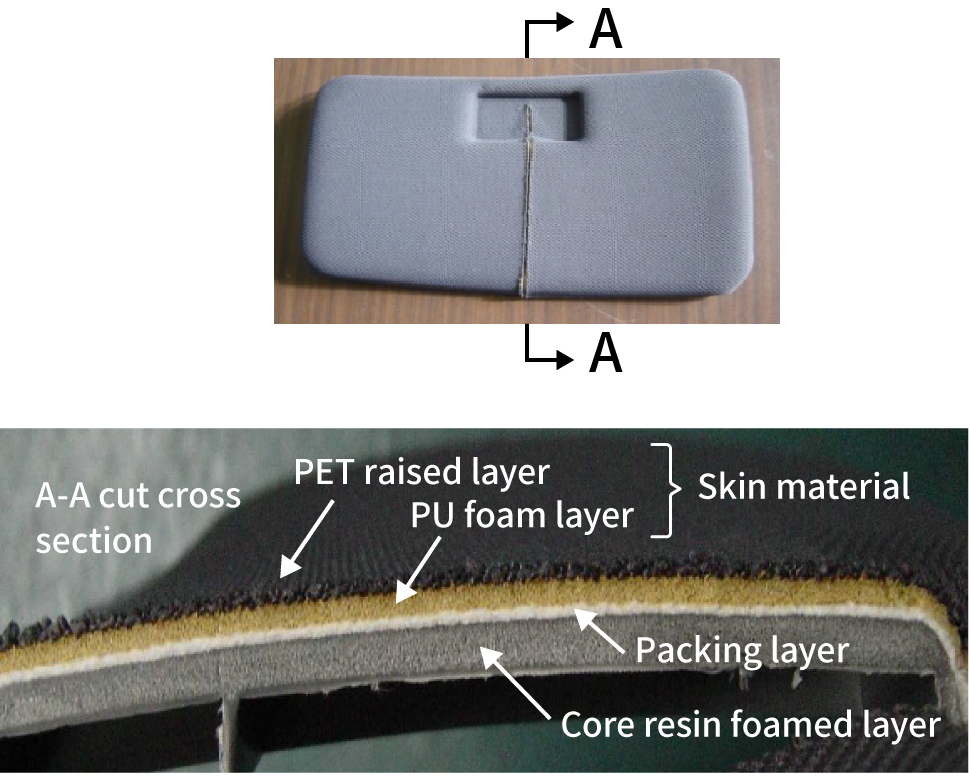

| Mode: | DIEPREST-C-Mode |

|---|---|

| Core Material: | PP |

| Skin Material: | PET fiber raised fabric |

| Product: | Pillar (Automotive) |

| Core material: | PP Foam |

|---|---|

| Skin material: | PET raised / PU foam |

| Product: | Glove compartment (Automotive) |

| Effects: | Skin ⇒maintains raised and cushioned feel Core resin ⇒Lightweight foaming (▲30%) |