UBE Machinery's Injection Molding

“IoT Solution”

We aim to make our customers' molding factories smart factories by providing systems and services along the lines of "production control," "quality control," "preventive maintenance," and "remote maintenance" using the quality information management system "SHOT-LINK i 2" that is compatible with the globalization of molding factories, thereby contributing to the improvement of productivity.

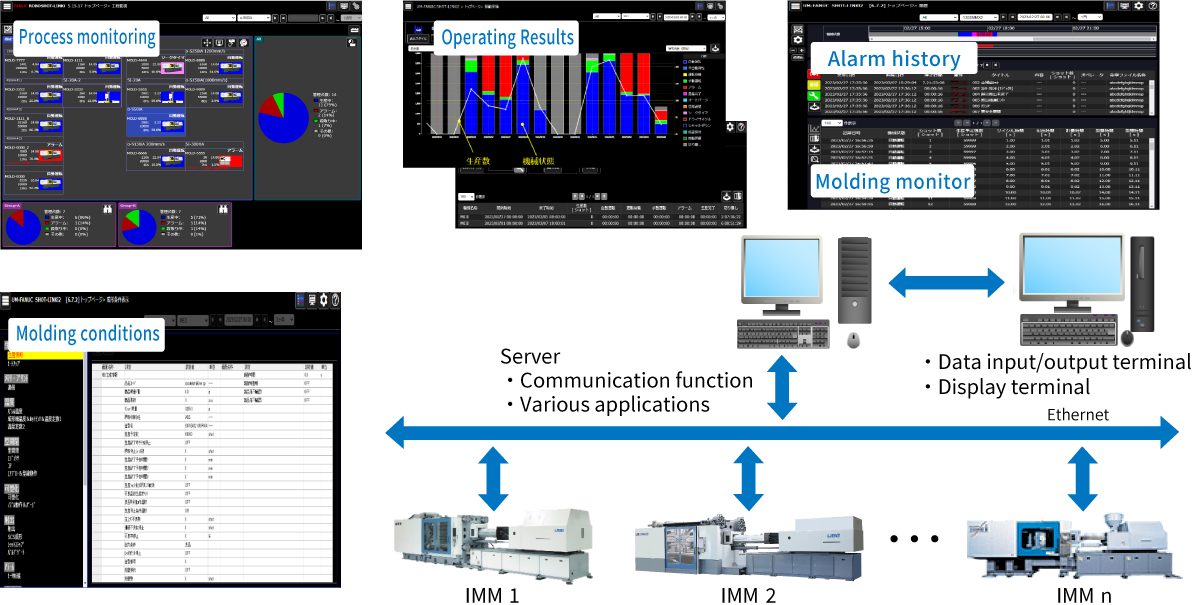

Centralized Management System

SHOT-LINK i 2 (Compatible with HH, em, MMX series)

Data is centrally managed by collecting data from injection molding machines connected to the network and storing it in a database.Various applications are provided to utilize the collected and accumulated data for production control and quality improvement.

(Note) "SHOT-LINK i 2" is production and quality information management software developed and provided by FANUC Corporation for injection molding machines, and is used in combination with software provided by UBE Machinery.

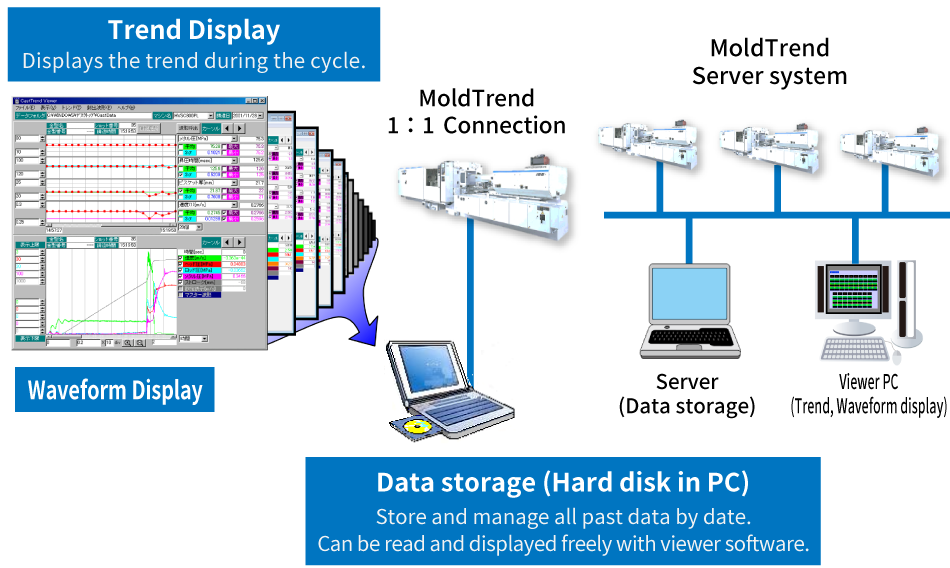

Mold Trend (Compatible with UF Series)

This system provides powerful support for both molding condition quality and management.

Molding data collection software using a personal computer, and the ability to capture all shot data simply by connecting to a personal computer with a LAN cable, make this system very effective for traceability.

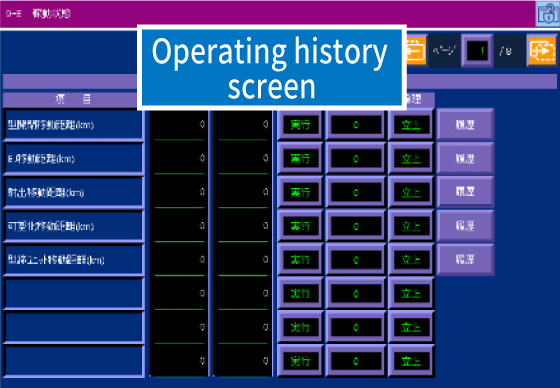

Predictive Diagnosis and Preventive Maintenance System

Preventive maintenance support using servo equipment data.

- Measurement and display of motor RPM accumulation, motor insulation resistance, and amplifier capacitance.

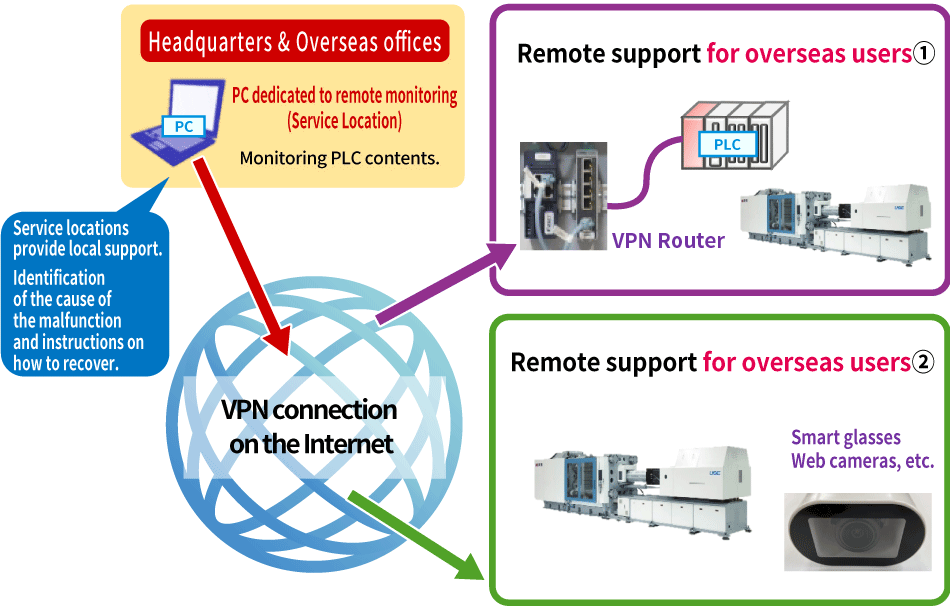

Remote Monitoring and Remote Support Systems

Service improvement: Providing high-quality services to customers worldwide.

- Service that makes customers feel no distance or time difference.

- Minimize production facility outages.