MMX Series

2-platen servo-hydraulic injection molding machine

MMX:1050~3000ton

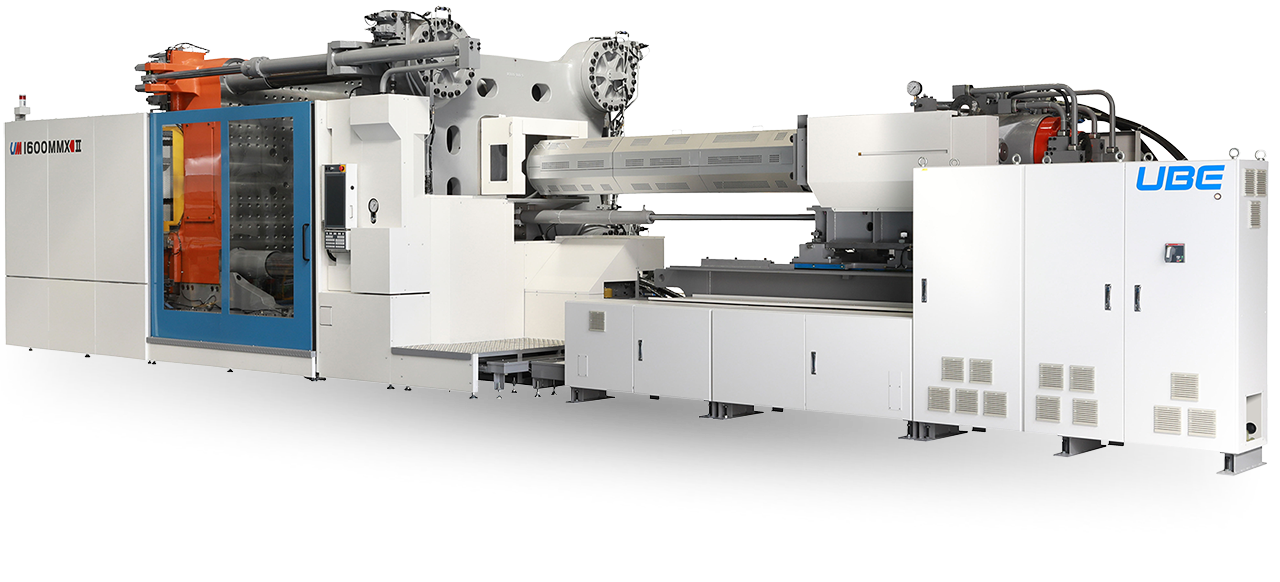

MMX II:1600ton

Pursuing production cost reduction. State-of-the-art, high-performance servo-hydraulic machines that meet customer needs.

MMX, MMX II Series / 2-platen servo-hydraulic injection molding machine

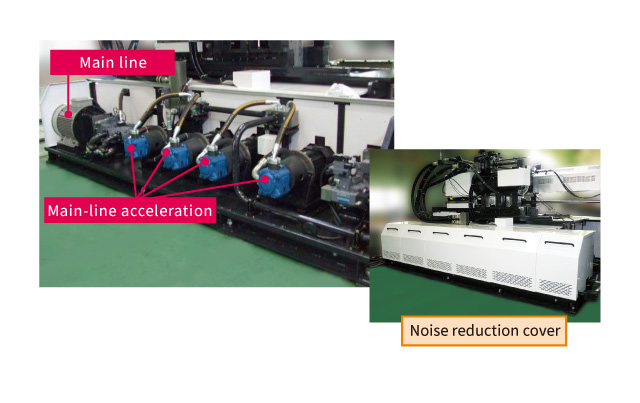

The MMX, MMX II Series is a large servo-hydraulic injection molding machine that promises a high level of reliability by integrating the latest technology with our long-proven expertise in two-platen mold clamping and injection systems. UBE Machinery's proprietary energy-saving pump control system combines energy savings with powerful continuous operation to help customers reduce production costs, improve productivity, and become carbon neutral.

<Features>

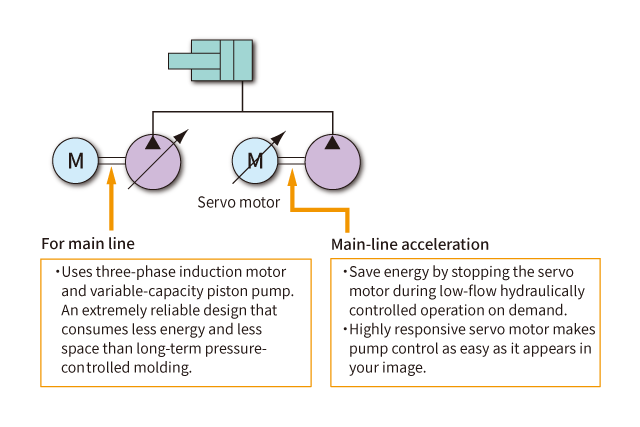

- UBE Machinery's proprietary "Energy-saving pump control system" that realizes energy-saving and powerful continuous molding operation.

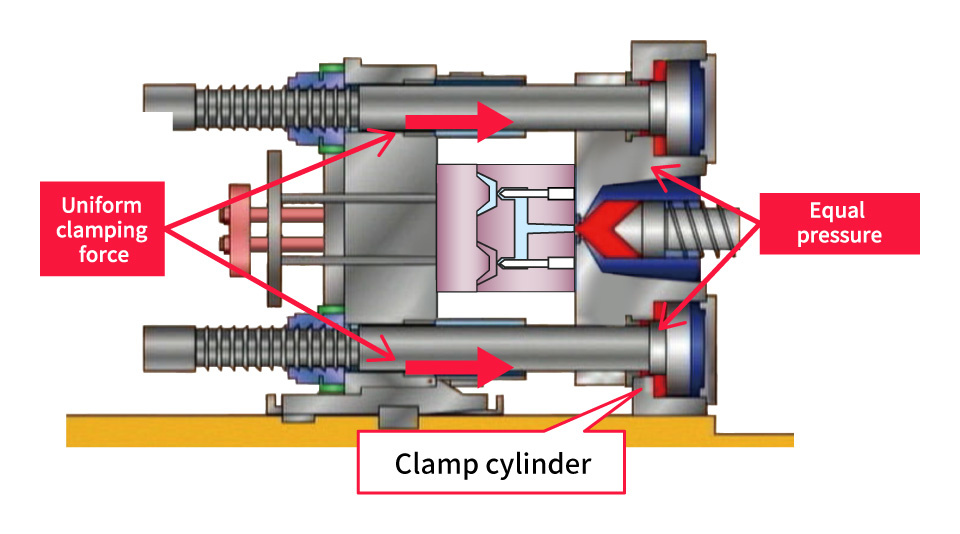

- Space-saving, lightweight, highly rigid, strong against unbalanced in-mold loads, and mold-friendly "2-platen mold clamping mechanism" with 4-axis tie bar for uniform mold clamping.

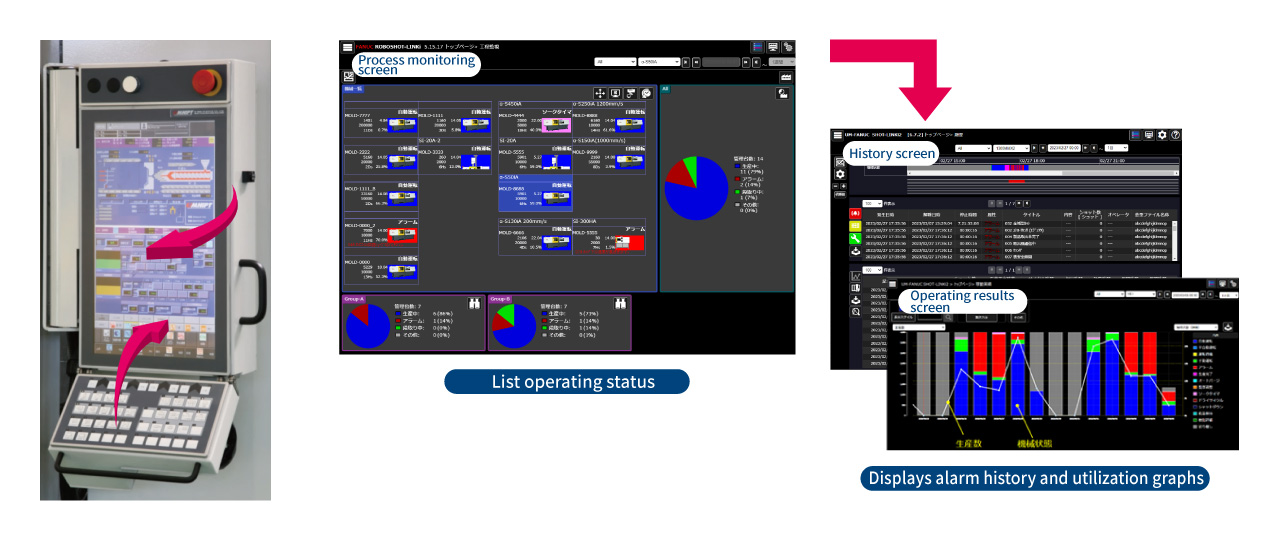

- Easy-to-operate "MAC-VIII+" (MMX series) and connected controller "MAC-IX" (MMX II series).

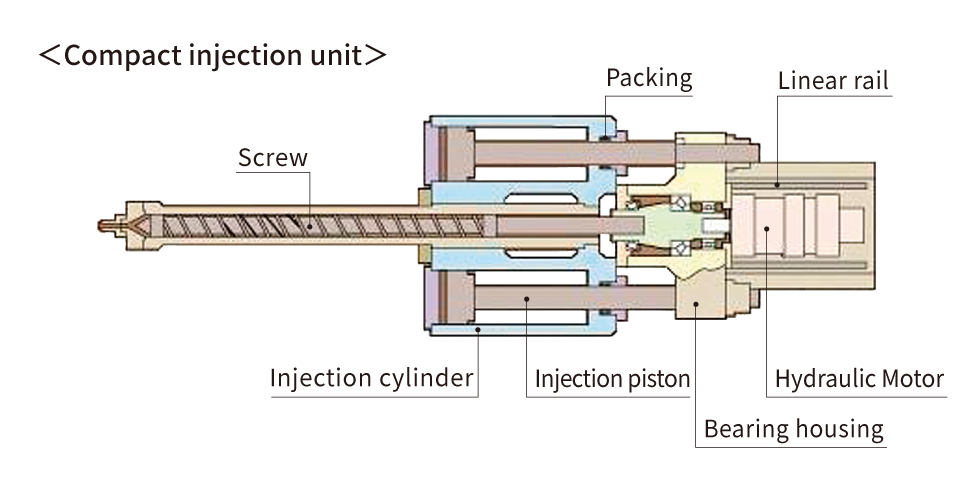

- Highly reliable and compact injection unit.

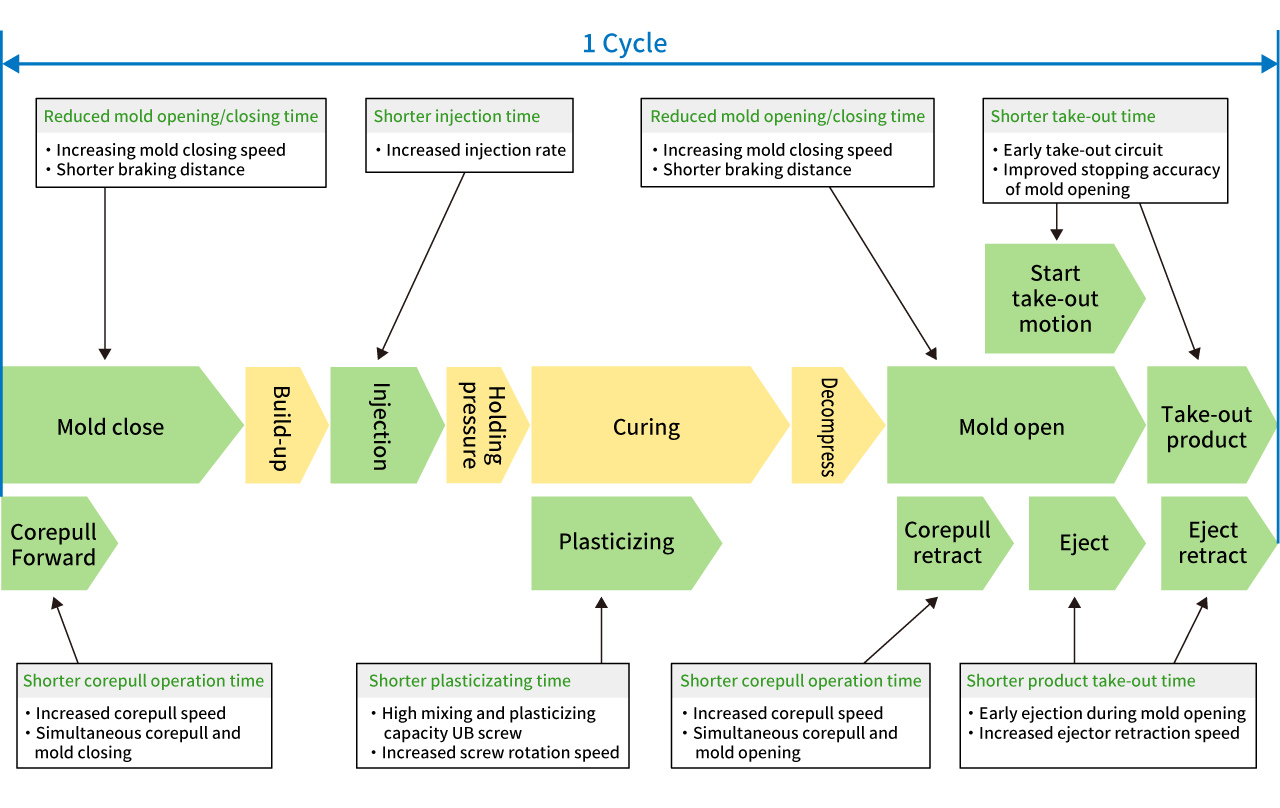

- Molding time reduction function for high-cycle molding operation is equipped as standard, contributing to customers' productivity improvement.

Product Features

*Click on a point in the image for details

1600MMX II

- Space-saving tie bar 4-point equalizing clamping mechanism.

- Easy-to-operate "MAC-VIII+" and "MAC-IX" controllers.

- Highly reliable and compact injection unit.

- Energy-saving pump control system contributes to carbon neutrality.

- Molding time reduction function for high cycle molding operation as standard equipment.

×