UBE Machinery's Injection Molding

"Advanced Family Mold Molding"

- SCS Molding -

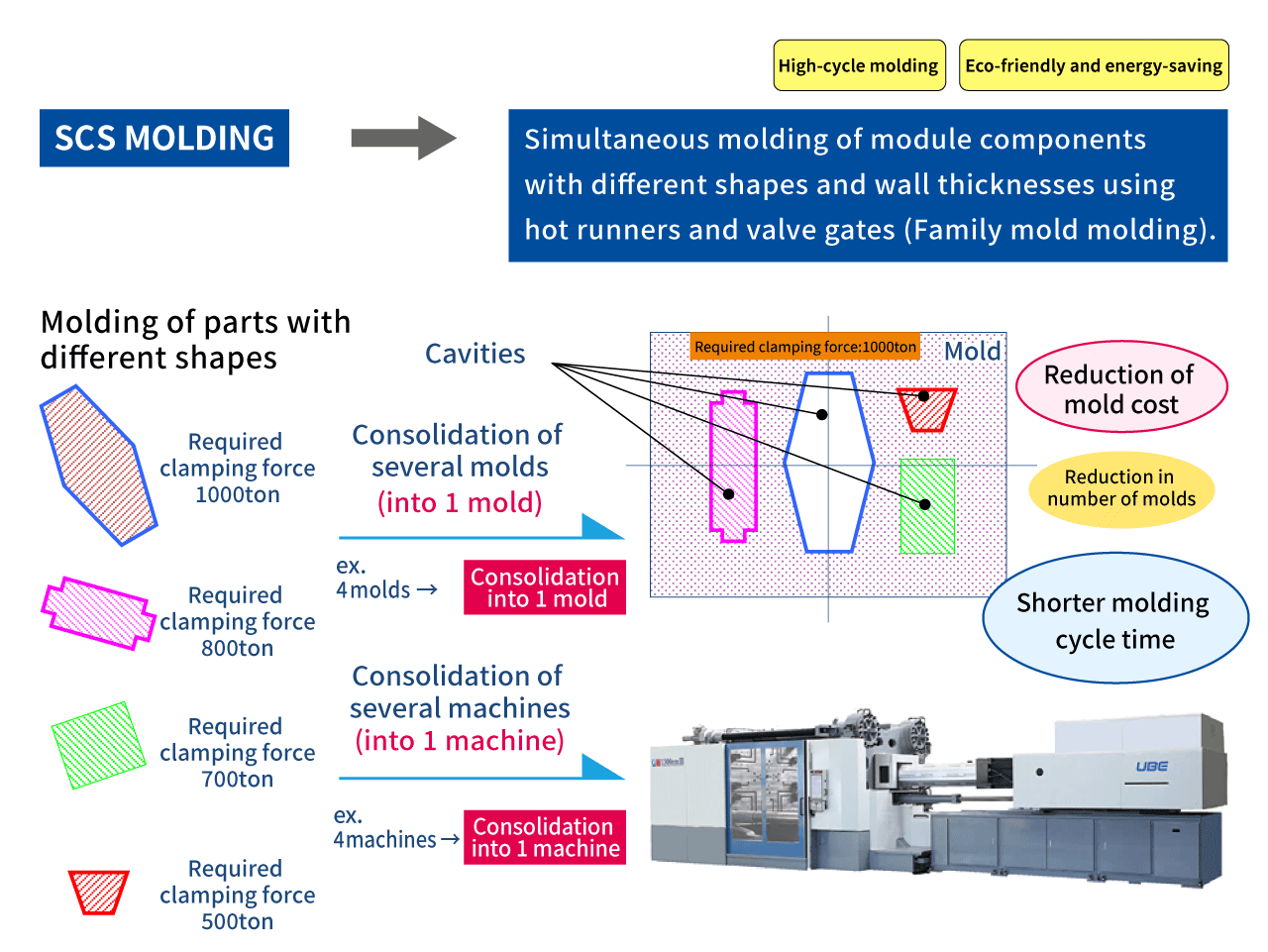

UBE Machinery's unique injection filling control system has made the filling accuracy of each product, which is one of the challenges of multi-cavity injection molding, practical up to the production quality level. We provide control that suppresses the increase in clamping force caused by multi-cavity molding while maintaining the existing high quality of products that were previously produced with multiple machines.

SCS Molding (Sequential Cavity Separation)

UBE Machinery's proprietary high-precision injection filling control technology enables high-quality simultaneous molding of multiple, different shaped module components to meet a variety of customer needs, including improved product quality, productivity, and reduced equipment and mold costs.

SCS:Registered trademark of UBE Machinery in Japan

Features

- Simultaneous molding of module components with different shapes and wall thicknesses (family mold molding).

- Reduction of mold cost and number of molds by one-mold molding.

- Simultaneous molding facilitates parts management and color matching (uniform color quality).

- Lower clamping force by sequential injection into each cavity.

- Minimizes cycle time extension by sequential injection in the order of product thickness.

- Add-on to the existing UBE Machinery's injection molding machines is possible.

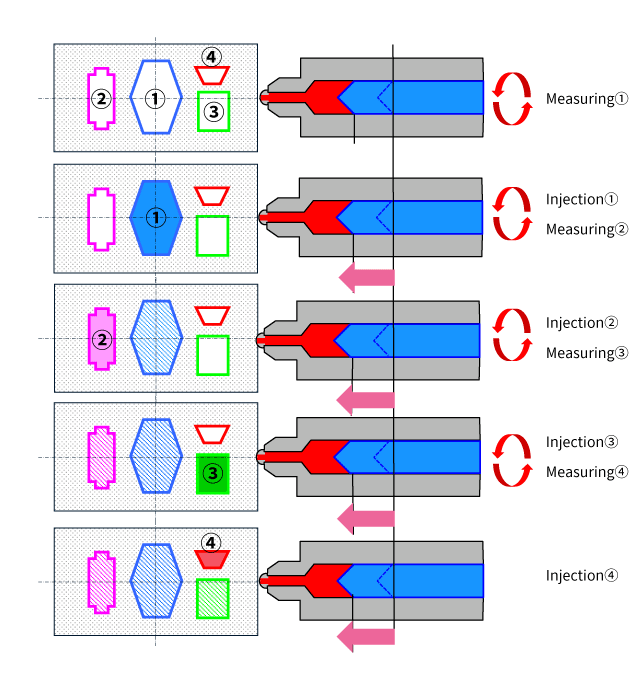

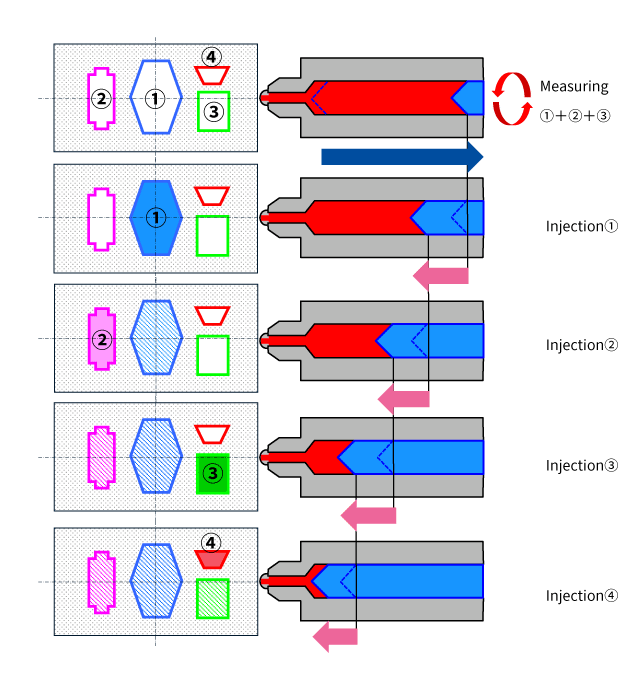

Patterns for measuring and injection mode

< SCS E-mode >

Measuring and injection mode for each product

(for UF series)

< SCS T-mode >

Batch measuring and sequential injection mode for all products

(for HH, em, MMX series)