Crane & Bulk Handling Equipment

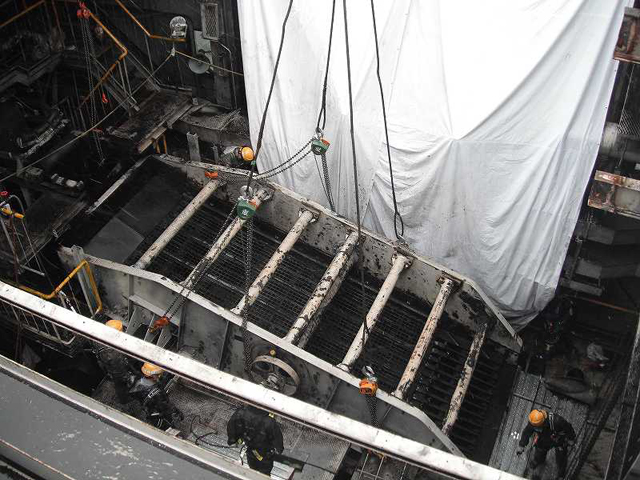

Belt conveyors, ship unloaders, cranes, etc.

Are you having trouble with the operation and maintenance?

- Severe corrosion of pillars, frames, and parts

- High vibration

- Repair method- Person for advice

- Person for advice

- No replacement parts

- Short life of consumables

- Difficult maintainability

- Applicable legal regulations

We provide engineering that is useful for equipment maintenance and management by proposing equipment diagnostic menus that meet customer needs.

Repair Service

- Restoring your equipment to its original performance -

Parts production/supply/maintenance/repair

We manufacture and supply parts (including consumables and spare parts).

We also handle maintenance and repairs depending on the situation.

Parts replacement/maintenance/supervision

We are able to provide maintenance work (inspection, modification etc.) and spare parts replacement. Our experienced supervisor(s) can be dispatched for those works.

Consulting Service

- Maximizing your equipment performance -

Equipment diagnosis

It is a technology that quantitatively evaluates the presence of abnormalities and the degree of deterioration by efficiently and effectively understanding the condition of equipment. Based on the diagnosis results, we propose repairs and improvements to the equipment.

Our diagnosis menu has the following two items.

Vibration analysis diagnosis

It is a technology that diagnoses the presence or absence of bearing abnormalities by measuring the vibrations emitted by rotating equipment such as electric motors and reducers and analyzing the frequency.

Furthermore, by continuing this diagnosis on a regular basis and accumulating data, it becomes possible to predict the lifespan of the equipment and contribute to preventive maintenance to prevent unexpected equipment troubles.

Applicable equipment

- electric motors

- reducers

- fans, blowers, etc.

Stress analysis diagnosis

It is a technology that identifies vital areas and diagnoses the degree of deterioration by measuring in detail the stress acting on steel structures that are subject to stress.

We are developing this technology for aging deterioration assessment. In addition, based on the diagnosis results, we can provide customers with services to extend the service life of equipment, such as repairing critical areas.

Applicable equipment

- overhead cranes

- horizontal cranes

- reclaimers

- stackers

- ship loaders, etc.

Upgrade Service

- Further expanding the capabilities of your equipment -

Environmental improvement/Energy saving/Capacity improvement/Life extension/

Cost reduction/Productivity improvement, etc.

We make proposals to meet customer needs such as environmental improvement, energy saving, capacity up, life extension, cost reduction, and productivity improvement.