Die Casting Machines

In addition to machine installation and service, our mission is to meet a wide range of customer needs, including modifications and renewals that contribute to environmental improvement, cost reduction, productivity improvement, and quality improvement, as well as relocation of production equipment in accordance with the optimization of production facilities.

Repair Service

- Restoring your equipment to its original performance -

Machine overhaul

We disassemble machines, replace consumable parts, and repair or replace damaged parts. By taking care of a wide area at once, we can restore machines to a near-new condition. The scope of work will be proposed based on the number of years of operation and the results of various machine inspections.

Consulting Service

- Maximizing your equipment performance -

Machine inspections

Machine inspection menu

- PM (Basic machine inspections package)

- Toggle inspection (condition inspection of toggle type Die clamping Unit)

- Injection Unit performance inspection

- Tie bar ultrasonic testing (early detection of cracks)

*Please feel free to contact us for more details and other inspections.

Training sessions

We offer training sessions to help our customers get the most out of machines. We have a lot of experience not only in Japan but also overseas, so please feel free to contact us.

Upgrade Service

- Further expanding the capabilities of your equipment -

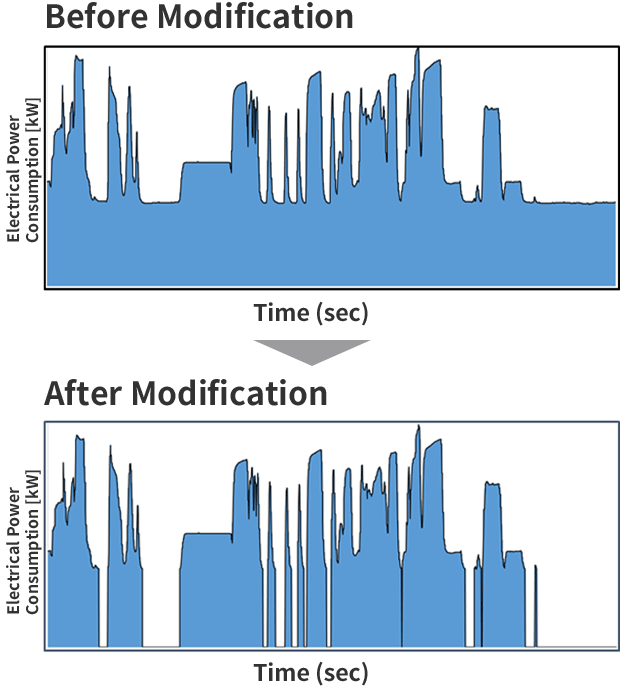

Servo pump system

We offer to replace induction motors for hydraulic pumps with servo motors. It enables hydraulic pumps to stop idling and reduce environmental impact by saving energy up to 30%(*).

*The energy-saving effect depends on the machine model and specifications, so please feel free to contact us.

In addition, cycle time can be reduced by utilizing the variable discharge flow rate of the hydraulic pump through servomotor speed control and by performing high speed operation at the appropriate timing.

Cast Doctor

We offer a system for machines to self-diagnose its condition. Cast Doctor has two functions, TBM and CBM, and supports planned preventive maintenance and stable production by early notification of parts replacement and abnormalities. The self-diagnostic data is accumulated and can be provided to us for early resolution of troubles.

Time Base Maintenance (TBM)

Suggest maintenance at fixed time intervals.

Condition Base Maintenance (CBM)

Suggest maintenance by monitoring the condition.

Retrofit

We offer a variety of retrofit(*) menus to ensure that our customers can use machines for many years to come.

Retrofit Menu

- PLC Renewal

- S-DDV Controller Upgrade (S-DDV_R)

- Injection. Speed Control Servo Valve Upgrade on Large Size Die Casting Machine (HS-DDV)

- Injection. System Upgrade on Large Size Die Casting Machine. (iV Series Specifications)

- Impact Control Valve Addition (ICV)

- Induction Motor Upgrade for Hydraulic Pump (Compliant with IE3 Motor Standard)

*For details and other retrofit menu, please feel free to contact us.