Injection Molding Machines

In addition to machine installation and service, our mission is to meet a wide range of customer needs, including modifications and renewals that contribute to environmental improvement, cost reduction, productivity improvement, and quality improvement, as well as relocation of production equipment in accordance with the optimization of production facilities.

Repair Service

- Restoring your equipment to its original performance -

Machine overhaul

We dismantle equipment, replace consumable parts, and repair or replace damaged parts. By taking care of a wide area at once, we can restore the equipment to a near-new condition. The scope of work will be proposed based on the number of years of operation and the results of various equipment diagnoses.

Consulting Service

- Maximizing your equipment performance -

Equipment diagnosis

Equipment diagnosis menu

- PM (Basic equipment diagnosis package)

- Toggle diagnosis (condition diagnosis of toggle type mold clamping device)

- Injection equipment performance diagnosis

- Tie bar ultrasonic testing (early detection of cracks)

*Please feel free to contact us for more details and other diagnostics.

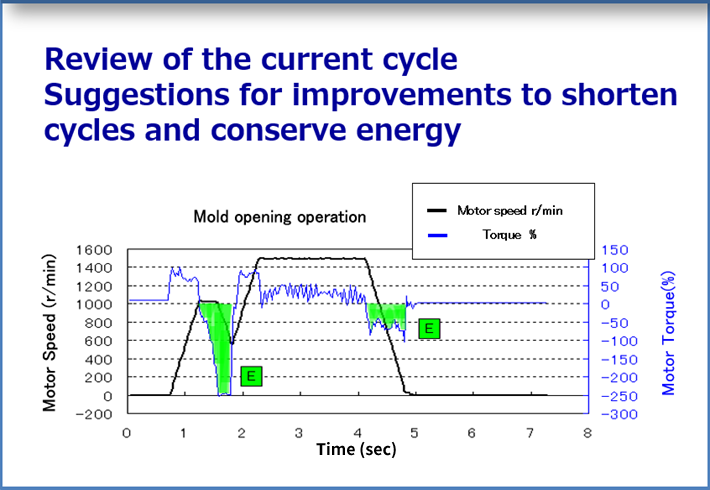

Energy-saving specifications that contribute to carbon neutrality

It is effective for measuring and analyzing the power consumption of your molding machine and identifying items that can save energy.

It is effective for process improvement to extract processes with high power consumption based on the measurement results of power consumption and review the molding conditions. We can also propose the most suitable modification items for you based on the analysis of power consumption.

Measure and analyze power consumption and propose optimal items based on the results.

- Cycle improvement (Improvement of wasted energy consumption)

- Eco Cylinder Cover (Improvement of power consumption of heat source)

- Electric plasticizing (reduce power consumption during plasticizing)

- High efficiency motorization (IE3)

The energy saving effect depends on the shape of the molded product, resin, and molding conditions used by the customer. Please consult with us about the energy-saving effects that can be expected from your injection molding machine.

*Please feel free to contact us for more details and other diagnosis.

Upgrade Service

- Further expanding the capabilities of your equipment -

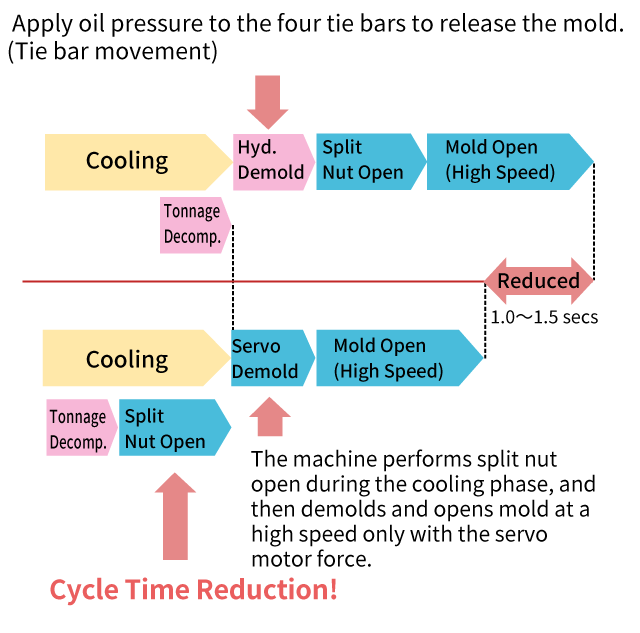

Servo-Demold circuit

By the time cooling is complete, the machine performs bucking and split nut opening, and mold release and mold opening are performed by the ball screw for mold opening/closing. This eliminates the time required for the split nut opening operation, which is already completed when cooling is complete, and the switching of the oil chamber supplying hydraulic pressure to the clamping cylinder, thus reducing cycle time.

Servo mold release means that the split nut is opened during the cooling process, and the mold release and high-speed mold opening are performed by the servomotor-driven ball screw for mold opening and closing, and the mold release operation that was performed by the clamping cylinder is driven at high speed by the ball screw for mold opening and closing.

Example of cycle time reduction when servo release circuit selected

| 1600em II | 1600em II | |

| Nomal mode | Servo Demold circuit | |

| Mold closing time | 3.98 sec | 3.98 sec |

| Mold open time | 4.01 sec | 2.43 sec |

| Dry cycle | 7.99 sec | 6.41 sec |

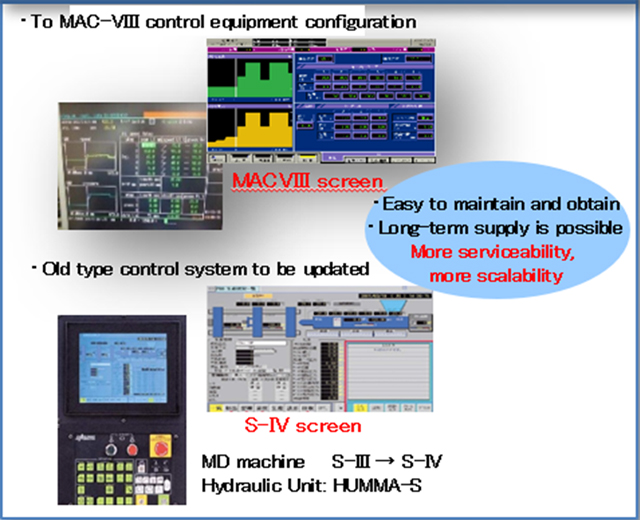

Retrofit

"Retrofit" is a technical term derived from "retroactive refit," which means to rebuild deteriorated machines and equipment.

Our retrofit work is not limited to machine repair (restore), but also includes updating your injection molding machine by installing the latest technology to meet the needs of the times, such as adding functions, improving accuracy, automation, and safety.

Upgrade menu after retrofit

- USB external storage device (additional number of mold memories)

- Screenshot function added (convenience feature)

- Packet Mac (data storage)

*For more details and other diagnostics, please feel free to contact us.