Kiln & Dryer

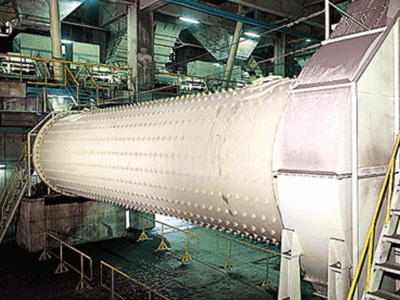

We mainly provide after-sales service (parts renewal, maintenance, function improvement) of ceramics-related equipment (kilns, dryers, tube mills, etc.), and our experienced engineers propose maintenance that meets customer needs, providing engineering useful for the maintenance and management of customers' equipment. Even if the equipment is not manufactured by our company, it is possible to propose maintenance and function improvement.

Repair service

- Restoring your equipment to its original performance -

Equipment maintenance

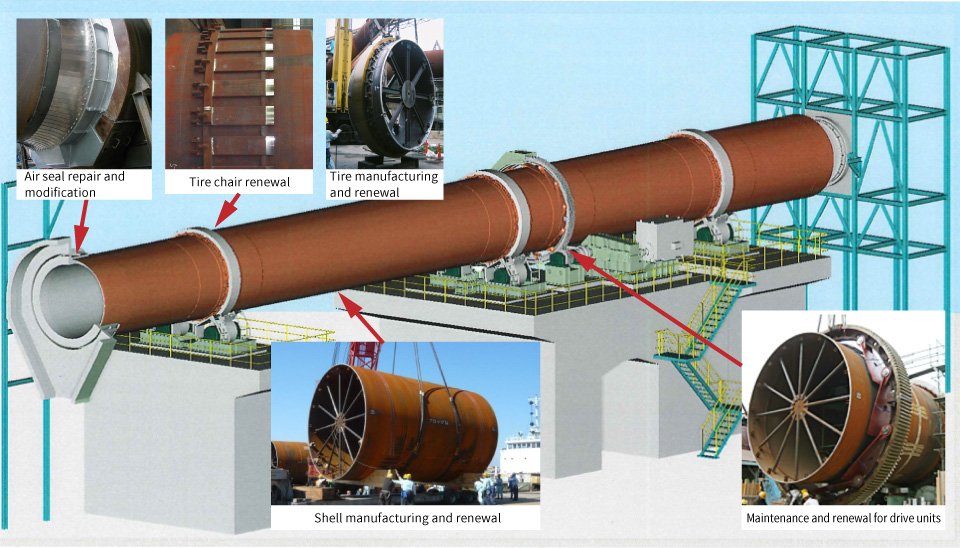

We perform maintenance, inspection, and parts renewal of large rotating equipment such as rollary kilns and rotary dryers, and contribute to the stable operation of our customers' facilities. In addition, we can handle a wide range of equipment made by other companies as well as maintenance, inspection, parts renewal, engineering, etc.

Modification, manufacture and maintenance of rotated equipment

Consulting service

- Maximizing your equipment performance -

Equipment Diagnostics

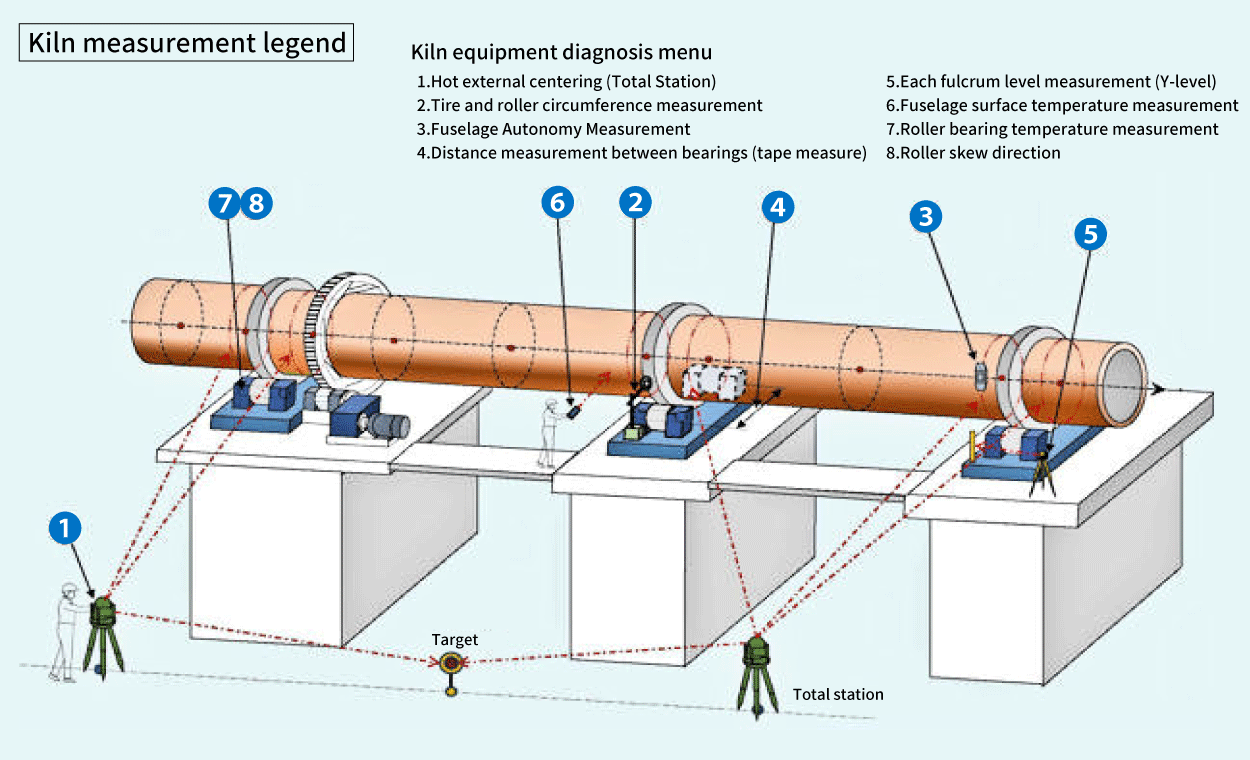

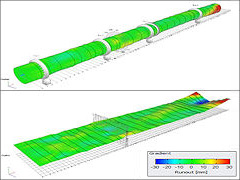

Equipment diagnosis measures the condition of the drive, support device, fuselage, etc. of the rotary kiln and rotary dryer to diagnose whether the operation is in proper condition. In addition, based on the results, we provide advice on equipment repair and improvement.

In addition, by regularly continuing this diagnosis and accumulating data, it is possible to predict the service life, contributing to preventive maintenance to prevent sudden equipment troubles.

In addition, we can conduct equipment diagnosis in Thailand and other Southeast Asian countries through cooperation with local companies.

We can perform various equipment diagnosis menus without stopping the kiln during operation.

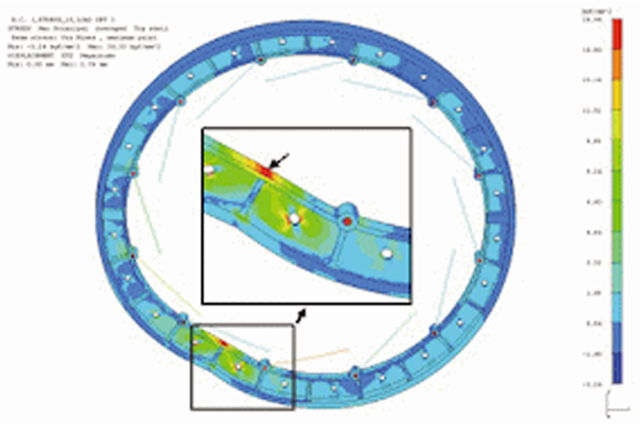

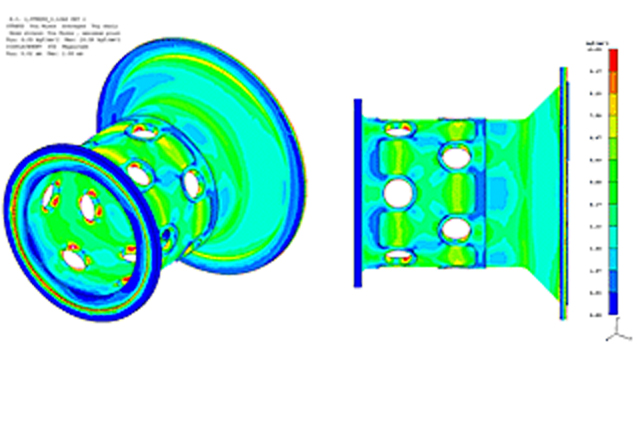

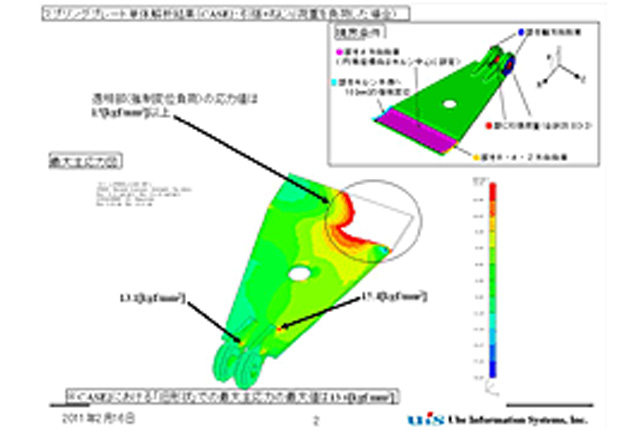

Stress Analysis

We conduct on-site surveys and FEM analysis using PCs for problems such as cracks and bolt breakage that occur in tube mill trunnions and kiln spring plates and girth gears. By performing FEM analysis, it is possible to examine all conditional assumptions, so it is possible to take effective measures.

Upgrade service

- Further expanding the capabilities of your equipment -

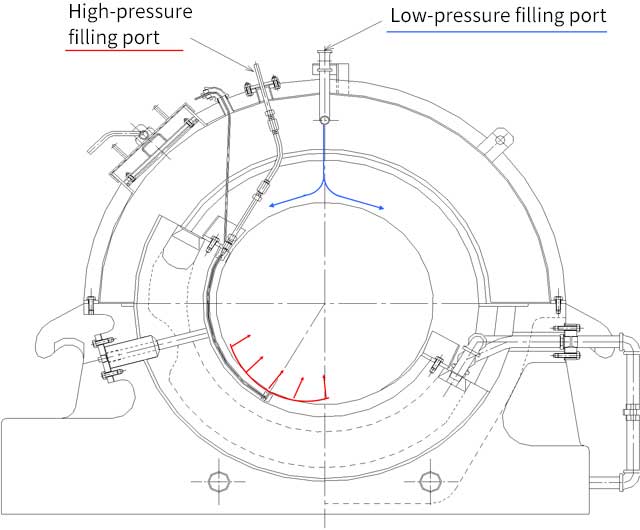

High-pressure oil-injected bearing bushings

By supplying lubricating oil at high pressure from the roller bearing bushings, an oil film is forcibly formed between the roller shaft and the bushings, preventing heat generation of the bearings and wear of the bushings.

In addition, by reducing the friction coefficient of the bearing, the driving force can be reduced, contributing to the energy saving of the entire equipment.

Hydraulic mobile thrustroller

Hydraulic mobile thrust rollers automatically raise and lower the kiln to uniformly hit the tire and rollers, girth gear and pinion, preventing uneven wear.

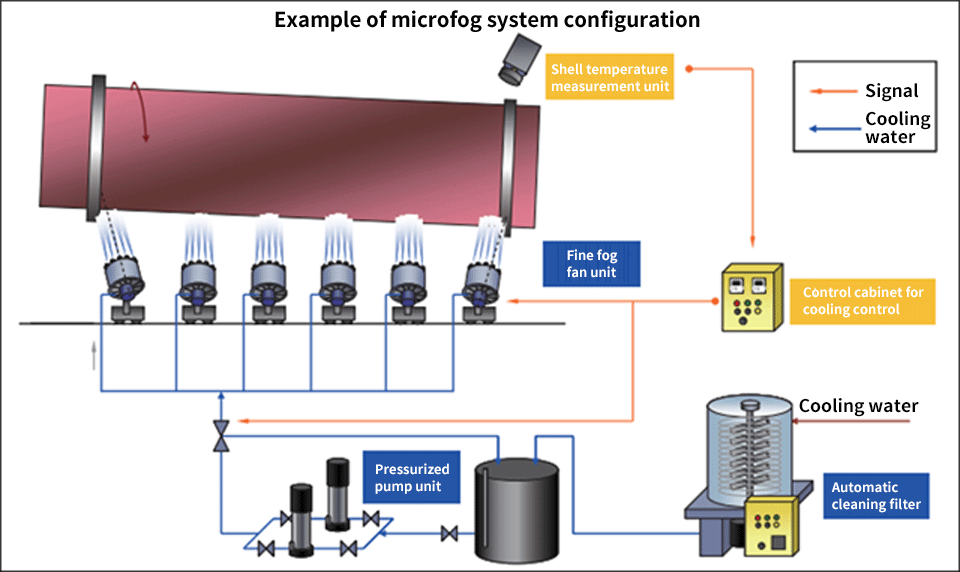

Fine fog cooling system

A device that cools the kiln fuselage by fine fog (mist with a small spray particle diameter).

Small particles evaporate easily in the air and take away the heat of vaporization, enabling efficient cooling.

<Advantages of introducing the system>

- 1) Life extension of kiln fuselage and fireproof brick

- 2) Long-term continuous stable operation of the kiln

- 3) Stabilization of coaching

- 4) Kiln fuselage temperature control

- 5) Because it is a "fine fog", there is no unevaporated water, and the surrounding environment is contaminated.

- 6) Flexible response to weather changes