UBE Vertical Mill

Utilizing our know-how as vertical mill manufacturer and the large-scale processing equipment at our own workshop, we respond to every request, from product production to maintenance of various parts, technical support, and on-site construction, contributing to the stable operation of vertical mill system.

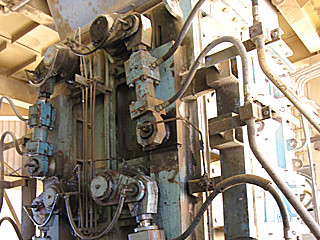

Repair Service

- Restoring your equipment to its original performance -

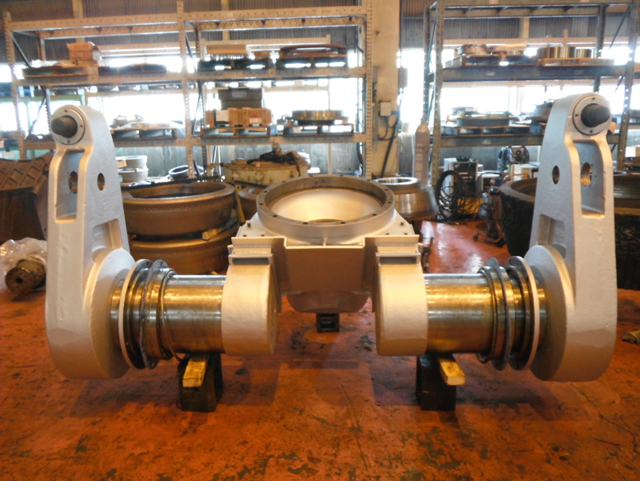

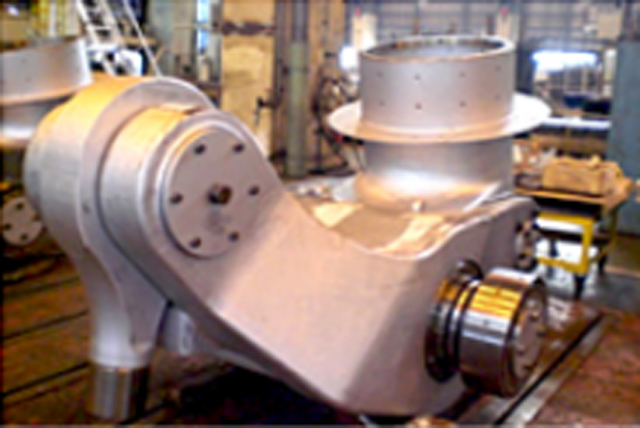

Maintenance for Mill parts

We dismantle and maintain the main parts of mill after long-term usage and restore them to fresh condition. Furthermore, we can provide the suitable maintenance proposal according to the inspection report during dismantling.

Supply of consumable parts & spare parts

We can provide suitable materials such as high chromium casting, hardfacing casting, ceramics inserted casting.

Consulting Service

- Maximizing your equipment performance -

Periodic inspections and technical support

We perform regular inspections of the mill system. We also provide prompt technical support for customer questions and concerns.

Upgrade Service

- Further expanding the capabilities of your equipment -

Performance improvement: Modification to new separators

By replacing the conventional type separator with the newest type separator (UNKS type), it is possible to improve the grinding capacity, reduce the vibration value, and reduce the power consumption.

Convetional type Separator

Newest type separator

Modification of Raw material feed air lock system

Contributes to reducing air leaks from the feed chute, preventing materials from adhering to the chute, and reducing maintenance costs.

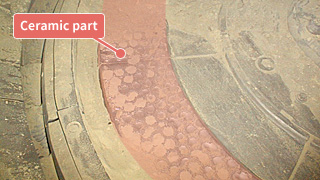

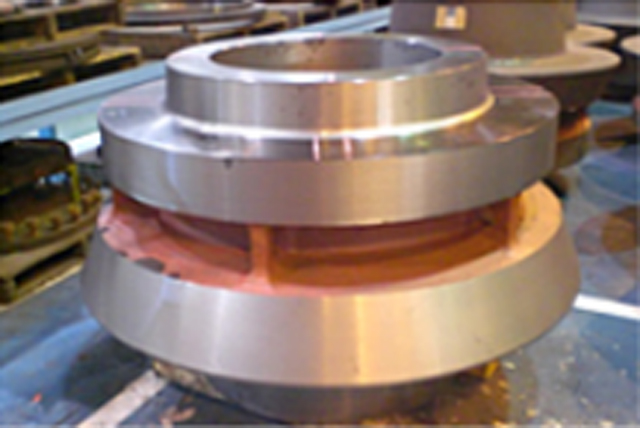

Ceramics inserted type roller tire & table liner

We supply highly wear-resistant ceramic embedded roller tires and table liners.

Features

- It has excellent wear resistance and it is possible to use under harsh operating conditions such as impact.

- Ensuring the stable performance by uniform wear.

- It is suitable for cement raw materials and slag grinding.