Air Floating Conveyor

This is an environment-friendly conveyor that does not generate dust and emits low noise. This belt conveyor transfers materials by floating the belt with air. Compared to conventional roller type conveyors, it operates with less noise and less power.

Additionally, it has a completely sealed structure, so there is no concern of material spillage or dust generation. A major feature is environmental friendliness, since it does not allow the smell of transported substances to leak out. All this contributes to our goal of a sustainable society.

Product Details

Air Floating Conveyor

Flexible design is possible as the support span can be lengthened.

Compactness allows it to be installed in a small space.

Features of UBE air floating conveyor

-

Rollerless

No rollers are used in the intermediate part, so there is no noise or vibration from the carrier and return sides.

In addition, maintenance such as roller replacement and fallen mine cleaning work is free. -

Air film supports the belt

Instead of rollers, the belt is supported by an air membrane.

Therefore, the coefficient of friction is smaller than that of conventional conveyors, so the motor capacity is reduced, making it possible to save energy. -

Completely sealed

Since the belt conveyor is completely sealed, dust and odors do not leak outside.

Therefore, it is the most suitable facility for environmental measures in urban areas and factories. -

Space saving

The loading cross-section is large and high-speed transportation is possible, so the equipment size is small.

Therefore, it is possible to save space by about 50% or more (compared to our company) compared to conventional belt conveyors.

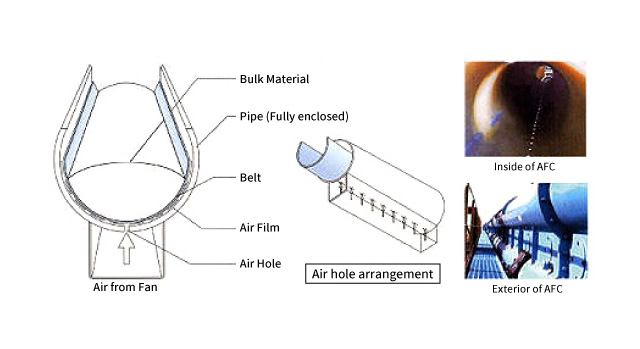

Basic Structure of UBE Air Floating Conveyor

The belt is supported by an air film without using rollers.

UBE Air Floating Conveyor Models by Capacity

| Type | MT series (small size) | MW series (medium size) | BU series (large size) |

|---|---|---|---|

| Cross-section |  |

|

|

| Capacity | ~100t/h | 100~1,500t/h | 1,000~5,000t/h |

| Belt Width | 300~650mm | 400~1,200mm | 1,000~1,600mm |

| Pipe Dia. | ― | 300A~900A | 750A~1,200A |

Air floating conveyor test facility

We have testing facilities on our premises. You can verify the tilt angle, speed, etc. that can be used to transport new items on an actual machine scale.

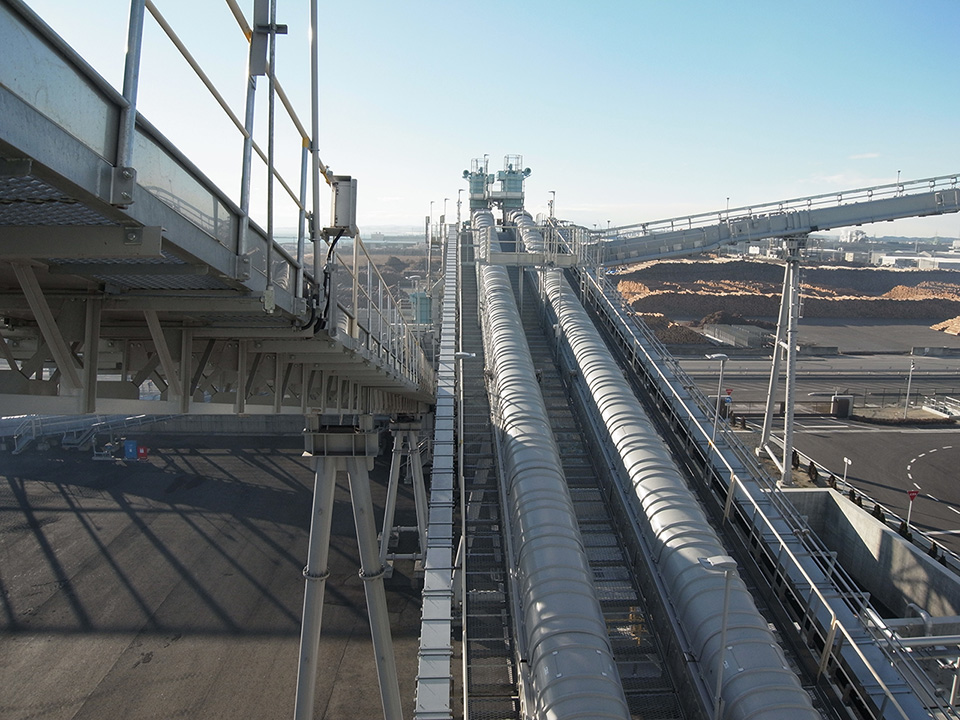

Belt conveyor

Structure of UBE Belt Conveyor

Receiving line

The unloaded coal is transported to the coal storage relay building by a belt conveyor.

From the relay building, the coal is transported to a stacker/reclaimer or stacker by a yard conveyor for coal storage.Discharging line

Coal discharged by the stacker/reclaimer or reclaimer is carried out of the yard by the yard conveyor.

Other conveyors

Information about our Crane & Bulk Handling Equipment services

Repair Service

Restoring your equipment to its original performance.

Consulting Service

Maximizing your equipment performance.

Upgrade Service

Further expanding the capabilities of your equipment.