SS Series

SS3G / SS5G

The SS series is a stem-slide, short-stroke extrusion press designed based on technology accumulated over many years.

The technology is suitable for high-strength aluminium extrusion as well as space-saving, energy-saving and high productivity.

The billet loader and stem slide have been electrically operated, and the hydraulic equipment and piping have been installed around the oil tank to reduce hydraulic oil consumption and make maintenance and inspection easier.

Strong Points

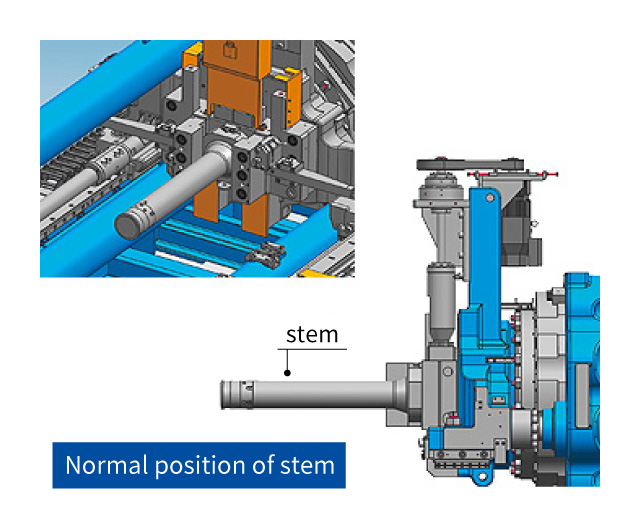

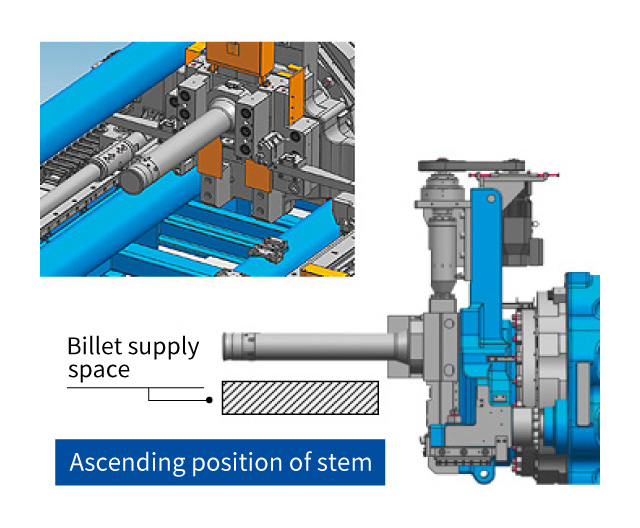

| 1. Space-saving | The short stroke with stem slide mechanism reduces the footprint by 15~20% compared to conventional machines. |

|---|---|

| 2. High productivity | The maximum billet length has been increased by 5-15% over the previous version, reducing idle time. |

| 3. Improved maintainability | Electric drive is used for the horizontal billet loader and die changer, significantly reducing the number of hydraulic pipes compared to conventional machines and reducing factors that cause oil leaks. |

| 4. Maintaining core accuracy | The adoption of a highly rigid one-piece machine base maintains the accuracy of the stem and container centres. |

| 5. Reduction of environmental impact | 20-25% reduction in hydraulic oil compared to conventional machines, reducing environmental impact. |

| 6. Improved operability | A touch panel has been adopted for the operation panel to improve visibility and operability. |

Structure of the stem slide mechanism