Extrusion Presses

Extrusion Presses

Applying creative technology and development expertise to meet customer needs for complex and precise profiles.

Our extrusion presses, press heated aluminum and copper billets through dies (metal molds) to produce a wide range of products, from building materials such as window sashes and curtain walls to industrial materials for automobiles, rolling stock, other transportation equipment, office, automation equipment, etc. As the only extrusion press manufacturer in Japan, our long history of experience combined with our unique technology makes it possible for us to answer the diverse requirements of not only customers in Japan, but around the world.

PRODUCT LINE-UP

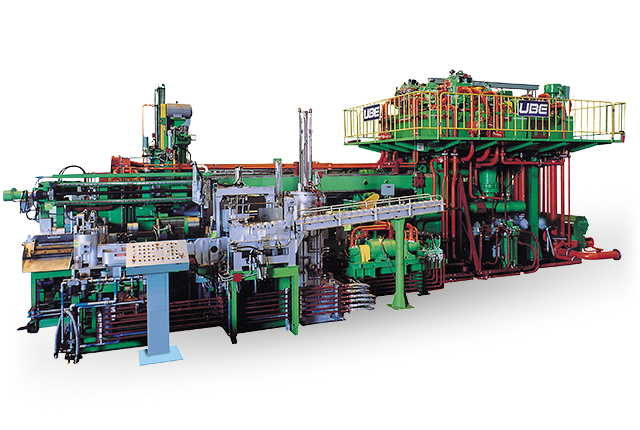

SS Series

The SS series is a series of stem-slide, short-stroke direct extrusion presses developed with the technological expertise attained at UBE over many years of experience in the industry. In addition to being compact, energy-efficient, and highly productive, these presses are also well suited for the extrusion of high-strength aluminum. In addition, the billet loader and stem slide are driven by motors. Hydraulic components are arranged around the oil tank for reduction of oil volume and easier maintenance and inspection.

SS Series SS3G SS5GSpecifications for high-strength materials (OPTION) IoT Solutions

-

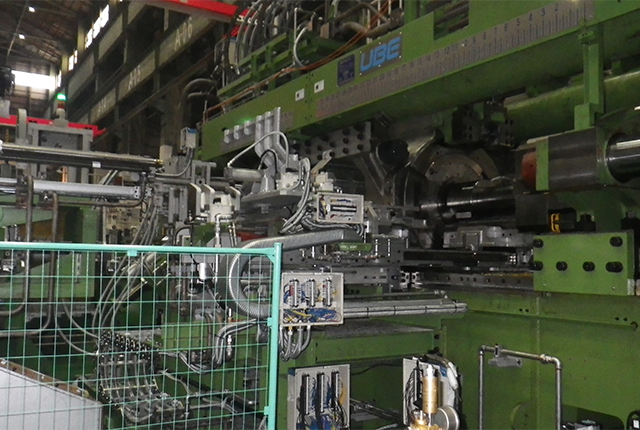

Indirect Extrusion Presses

Indirect extrusion is suitable for production of hard alloy parts, such as materials of components for transportation equipment. Since indirect extrusion enables simultaneous movements of the container and the stem during extrusion, it realizes uniform metal flow with minimal friction between the container and the billet. In addition, UBE's indirect double-action extrusion press for aluminum has automated the handling of the free die, the shell and the discard. It also features superb operability with a fully automatic die cassette changer system (lift type).

-

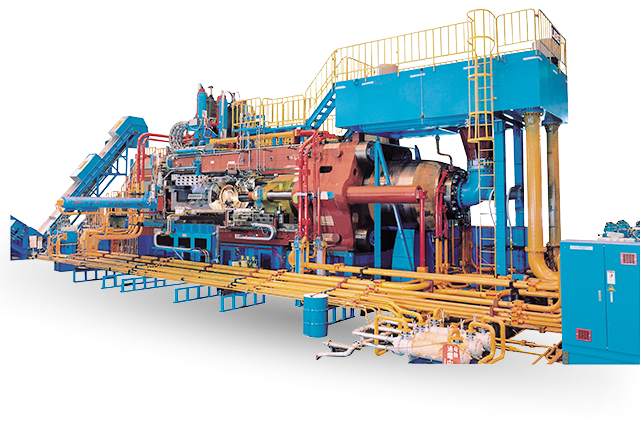

Direct Double-Action Extrusion Press for Copper

This is the extrusion press for the production of tubes of copper or copper alloys. UBE’s direct double-action extrusion press for copper has the excellent operability brought by automated handling of the discard, the dummy block, the shell and the clean- out disc, along with the automatic die changer.

-

Indirect Single-Action Extrusion Press for Copper

This is the extrusion press for the production of wires and rods of copper or copper alloys.

Indirect extrusion makes it possible to use larger and longer billets, achieving in high productivity. In addition, UBE’s indirect single-action extrusion press for copper has the excellent operability brought by automated handling of the free die, the clean-out disc and the shell.

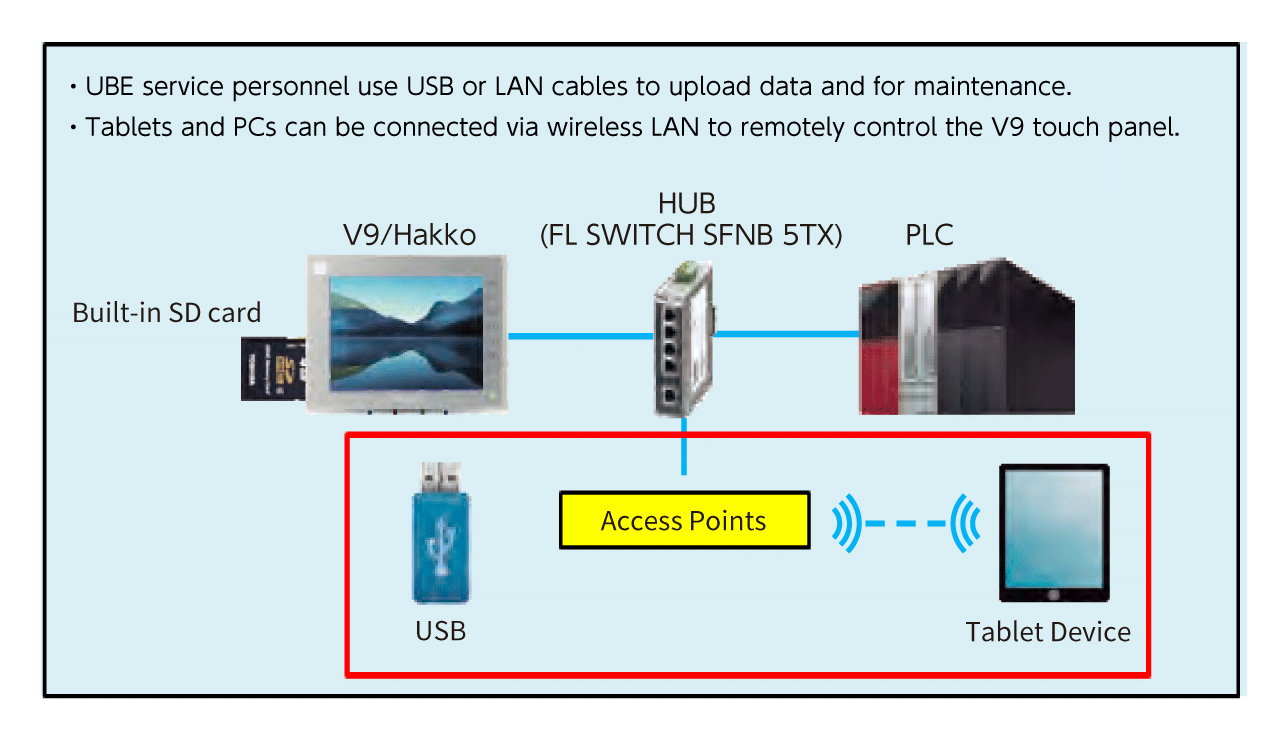

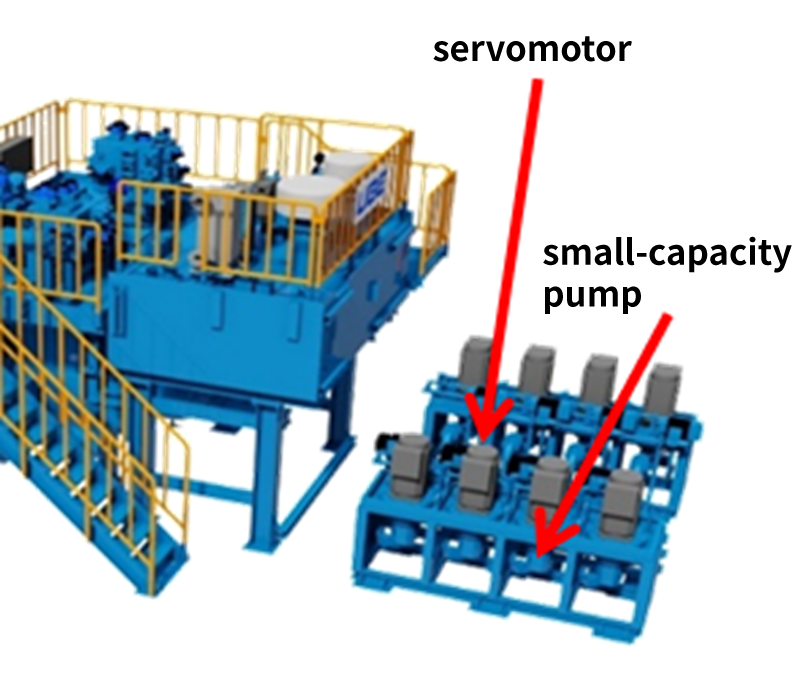

Solutions (SS5G)

Energy Saving

reduction rate: 30~50%

small-capacity pump and servo motor.

35%~50% energy savings compared to conventional systems.

DOCUMENT DOWNLOAD

Information about our Extrusion Press services

Repair Service

Restoring your equipment to its original performance.

Consulting Service

Maximizing your equipment performance.

Upgrade Service

Further expanding the capabilities of your equipment.