UBE Machinery's Injection Molding

“Technology to Improve Operating Rates”

We propose technologies to improve the efficiency of production start-up based on labor and manpower savings.

Reduced setup time

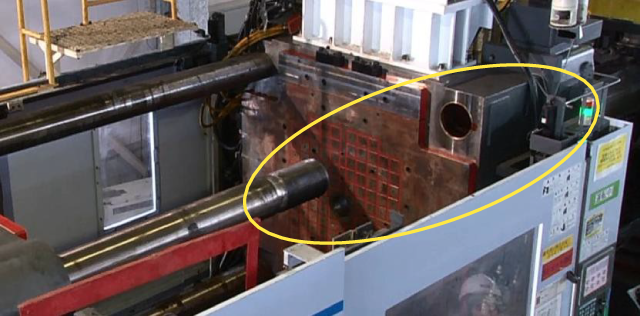

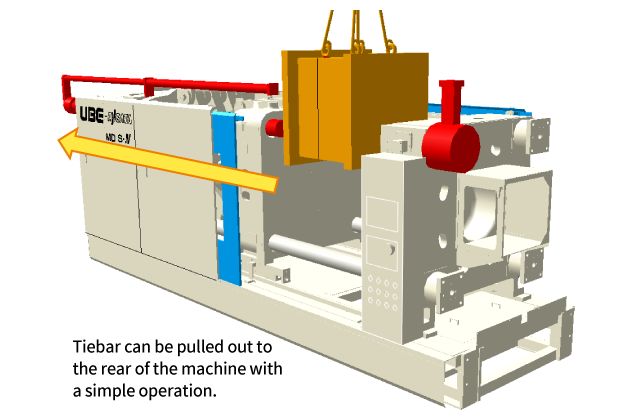

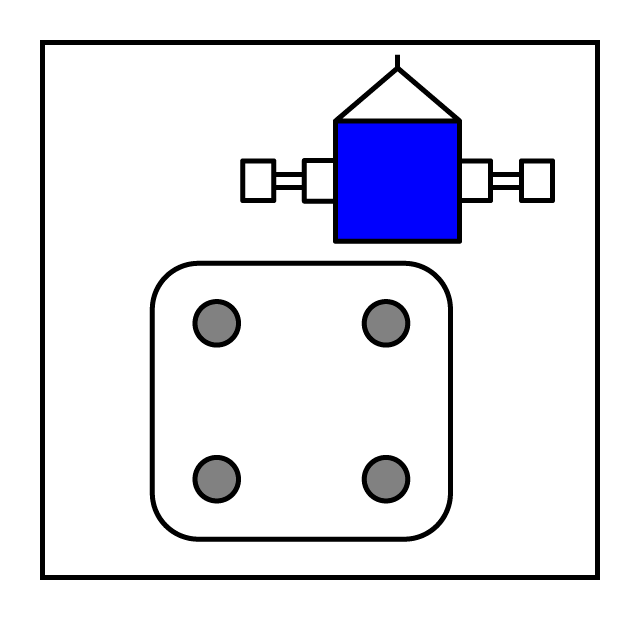

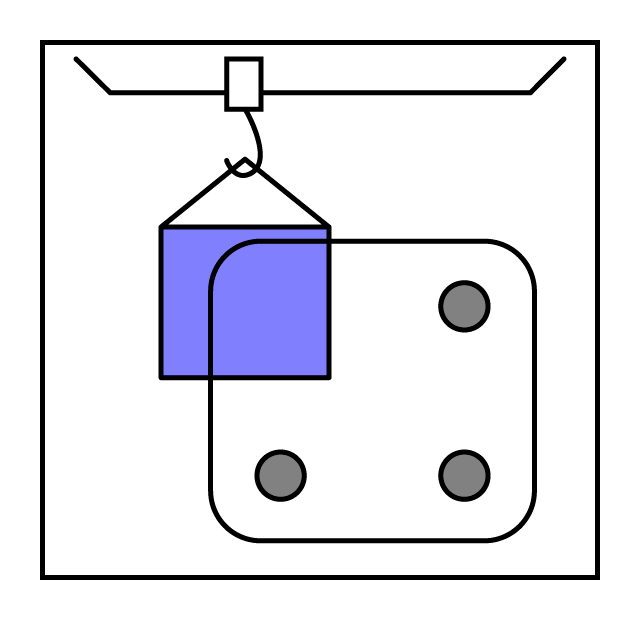

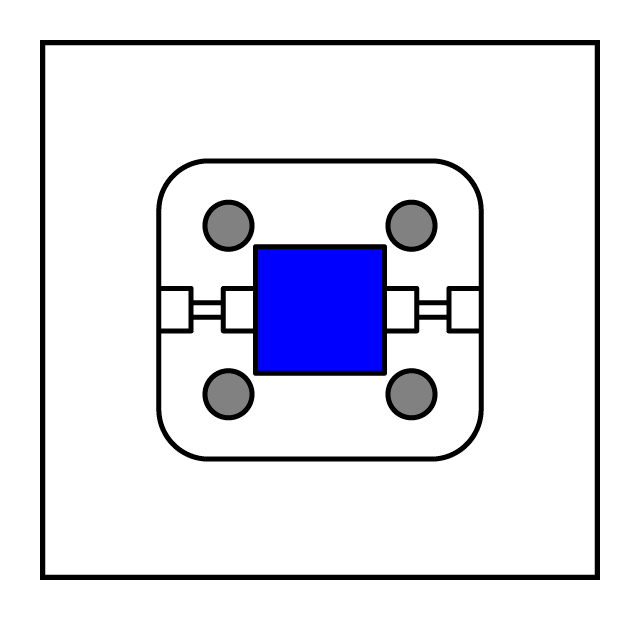

"Tiebar Puller" (Toggle type injection molding machine : HH, UF series)

Eases restrictions such as factory height and facilitates large mold changes.

- The ceiling is too low for a crane to change molds!

- Large molds cannot be mounted!

- We want to install a mold without changing the equipment attached to the mold!

"Tiebar Puller" provides

the following advantages!

Reduced mold replacement time

- No need to disassemble even complex molds with many accessories, such as cylinders for corepulls.

- Significantly reduced replacement time.

Efficient Use of Existing Factories

- Efficient factory utilization with the current building due to relaxed height conditions and regulations in the factory.

- Highly economical for new plant construction.

From Large to Small

- Tiebar spacing restrictions have been relaxed, and molds that used to be molded on unnecessarily large machines can now be molded on appropriate small machines.

Optimal Mold Design

- Tiebar spacing restrictions are relaxed, allowing for more freedom in mold design to suit the product.

Space Free

- Height requirements for the installation of molding machines have been relaxed, making it possible to install large machines that were previously impossible to install.

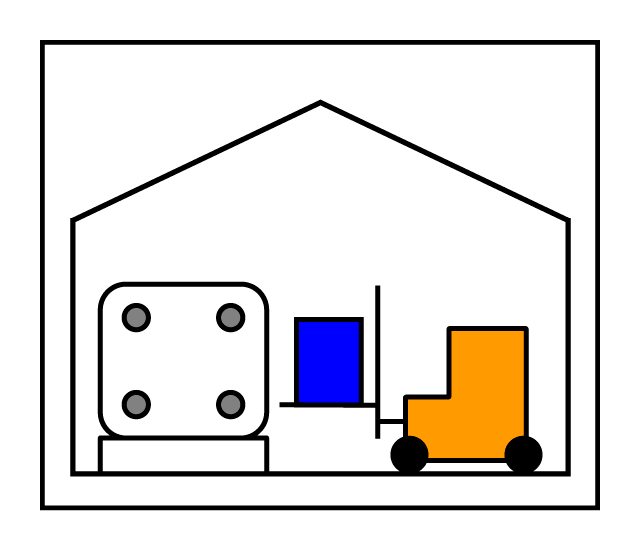

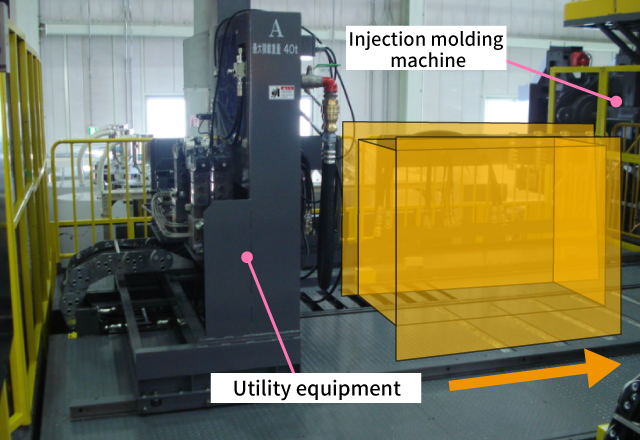

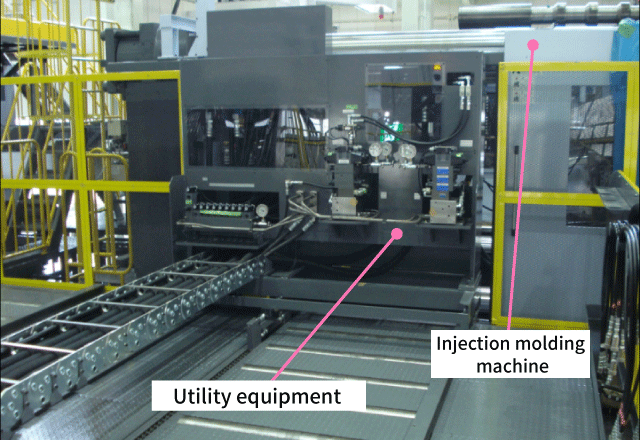

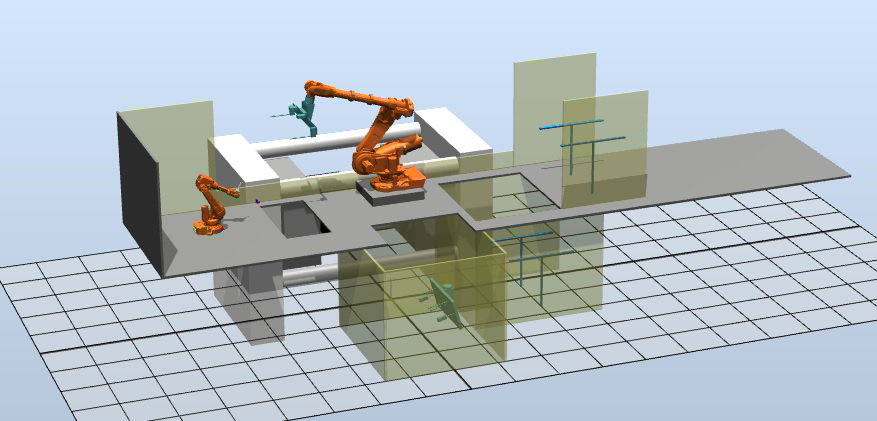

Automation System

UBE Machinery, with its many years of experience in this field, is able to propose automation systems such as mold change carts, take-out robots in response to customers' requirements.

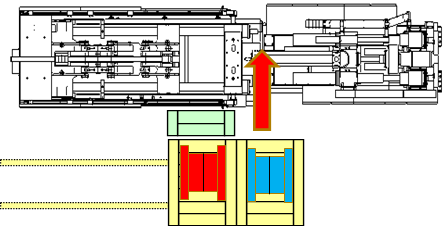

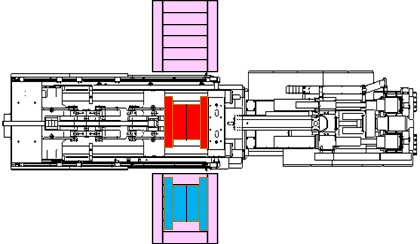

Example of Drip Cart Method Mold Change

Mold is brought in while preheating and temperature control is maintained. ⇒ Molding starts.

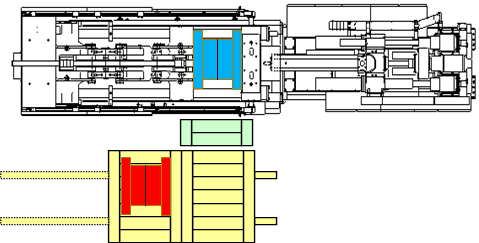

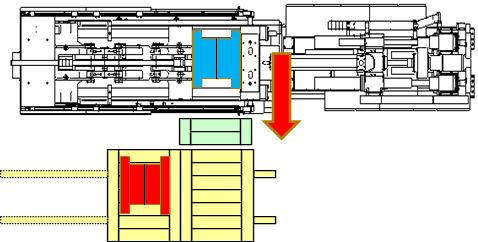

One-way mold change

Standby for mold change

Standby for mold change Mold unloading

Mold unloading Mold unloading completed / 1 pitch cart move

Mold unloading completed / 1 pitch cart move Before the next mold delivery

Before the next mold delivery After the next mold delivery

After the next mold delivery

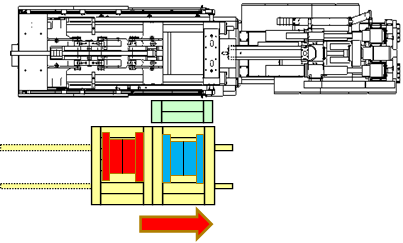

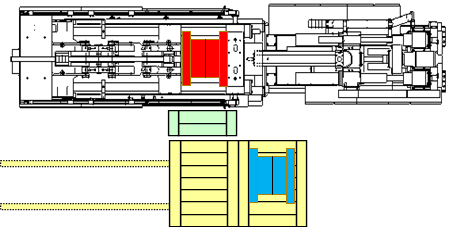

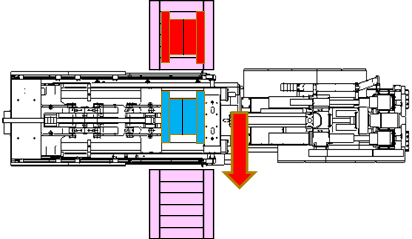

Successive pushing-out style mold change

Before simultaneous loading/unloading of old and new molds

Before simultaneous loading/unloading of old and new molds Completed simultaneous loading/unloading of old and new molds

Completed simultaneous loading/unloading of old and new molds

Example of multifunctional product take-out

Rapid color change

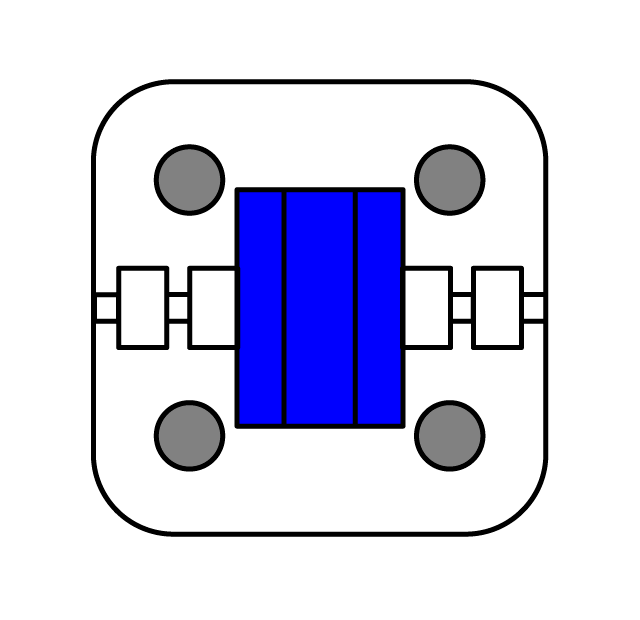

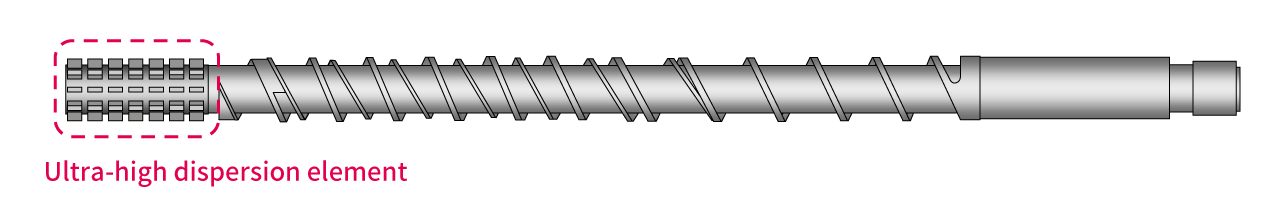

Ultra-high mixing and dispersion screw (MF-UB)

The ultra-high dispersion function disperses and dilutes color residue, enabling reduction of purging resin volume and purging time for color change.

MF-UB screw / Reduced purging material due to improved color changeability (vs. mixing nozzle)

| [Purging material reduction effect] | Amount of resin required for color change (index) |

|---|---|

| Mixing nozzles | 100 |

| MF-UB SCREW (OPTIONAL) |

25 |

| Reduction effect | 75% reduction |