Dryer/Cooler

We have a large number of experience in manufacturing Rotary dryers for drying coal, carbon, ore, slag, clay, sludge, etc., and Rotary coolers for cooling powdered and granulated materials such as quicklime, raw materials for chemical fertilizers, cement, etc.

Product Details

Rotary dryer

Many of them have a body diameter of about 1 to 5 m, and there are parallel flow type and counter flow type. The main dry raw materials include coal, carbon, ore, steelmaking slag, and chemical fertilizer raw materials.

Features of UBE rotary dryers

- Easy to operate and continuous operation.

- Suitable for large-capacity processing (processing capacity: about 10~200t/h).

- Indirect heating type can also be manufactured to prevent impurities from entering.

- Based on the raw material properties and achievements, we select one with high drying efficiency from a variety of lifter structures.

- Concentralization can also be installed to improve drying efficiency.

- Hammering device on the outside of the fuselage and chains inside the fuselage prevent adhesion and accumulation of raw materials.

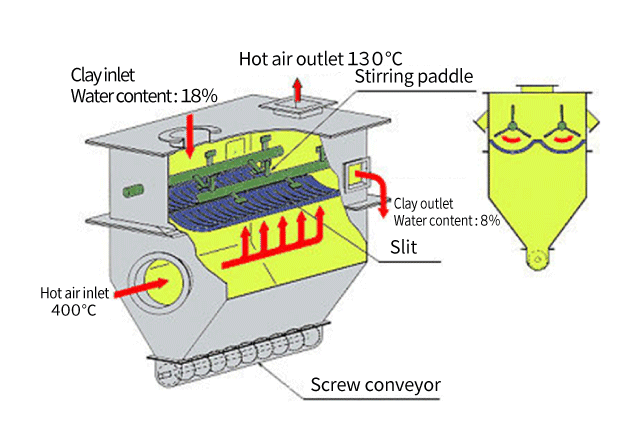

Paddle dryer

The paddle dryer is a flow stirring type and has an aeration and stirring drying mechanism, enabling high-speed and high-efficiency drying. The main drying raw materials are clay, sludge, steel slag, etc., and they are very effective in the effective use of waste.

Features of UBE Paddle dryer

- Compact body, small occupancy area, low initial cost.

- Exhaust heat (exhaust gas) generated in the factory can be used for high-temperature gas (~435°C), which is a drying heat source.

- Drying at high speed is possible because the raw material is dried while stirring (processing capacity: about 1~30t/h).

Structure diagram of Paddle dryer

Equipment Specifications

- 1. Dry raw materials ・・・ Clay

- 2. Capacity ・・・ 30T/H (W.B.)

- 3. Dryness (Water content) ・・・ Inlet:18% Outlet:8%

- 4. Power ・・・ 30kw X6P

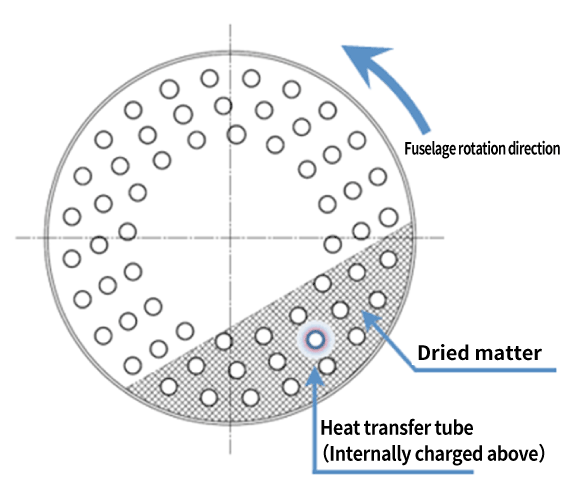

Steam tube dryer (Supplying only in Japan)

A steam tube dryer (STD) is an indirect heating furnace with a large number of heat transfer tubes inside the fuselage, and is dried by contact between the heat transfer tube heated by steam and the object to be dried.

Continuous large-capacity processing is possible.

Features of UBE Steam tube dryer

- Compared to other models, the structure is simple, so it is suitable for continuous and large processing.

- Changes in the workpiece (quantity, moisture content) can be easily accommodated by adjusting the steam temperature and residence time.

- High thermal efficiency compared to other models.

- Since the amount of carrier gas is small due to indirect heating, the exhaust gas treatment equipment is compact.

Conceptual diagram of structure

Structural-conceptual model

Rotary cooler / Vertical cooler

Rotary coolers are equipment for cooling the fired raw materials, and many of them have a barrel diameter of about 2~4m, and the main cooling raw materials are cement raw materials, chemical fertilizer raw materials, oil coke, iron ore, alumina, etc., and the cooling methods include internal air cooling type and external water cooling type.

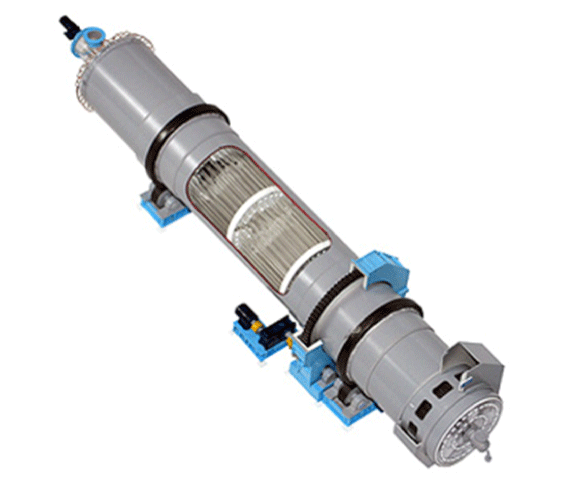

A vertical cooler is a device that indirectly cools powders such as cement with cooling water.

Features of UBE rotary cooler

- Easy to operate and continuous operation for a long time.

- Suitable for large-capacity processing (processing capacity: about 10~200t/h).

Features of UBE vertical cooler

- Small installation area due to compact equipment.

- Low initial cost due to small/compact equipment.

- Easy maintenance with few maintenance points.

UBE's drying/grinding technology

Collaboration between drying technology and grinding technology

When grinding coal, etc., proper drying in the previous process may be required.

In that case, we can make proposals that make use of our expertise in vertical mills, and we can make proposals that comprehensively optimize the drying ~ grinding process.

Integrated testing from drying to grinding is possible

In close proximity to the steam tube dryer test facility, we have vertical mill testing equipment that can perform integrated testing from drying to grinding.

For example, it is possible to consistently conduct tests related to the "coal drying ~ crushing process" in coal-fired power plants.

Information about our Kiln & Dryer services

Repair Service

Restoring your equipment to its original performance.

Consulting Service

Maximizing your equipment performance.

Upgrade Service

Further expanding the capabilities of your equipment.