UBE Vertical Mill

UBE Vertical Mill

Strong Points

- Energy Saving (Less than 30% compared to Ball Mill)

- Possible to carry out simultaneously with grinding, drying and classifying

- Simple equipment configuration

- Excellent maintainability

- Unique vibration absorbtion technology

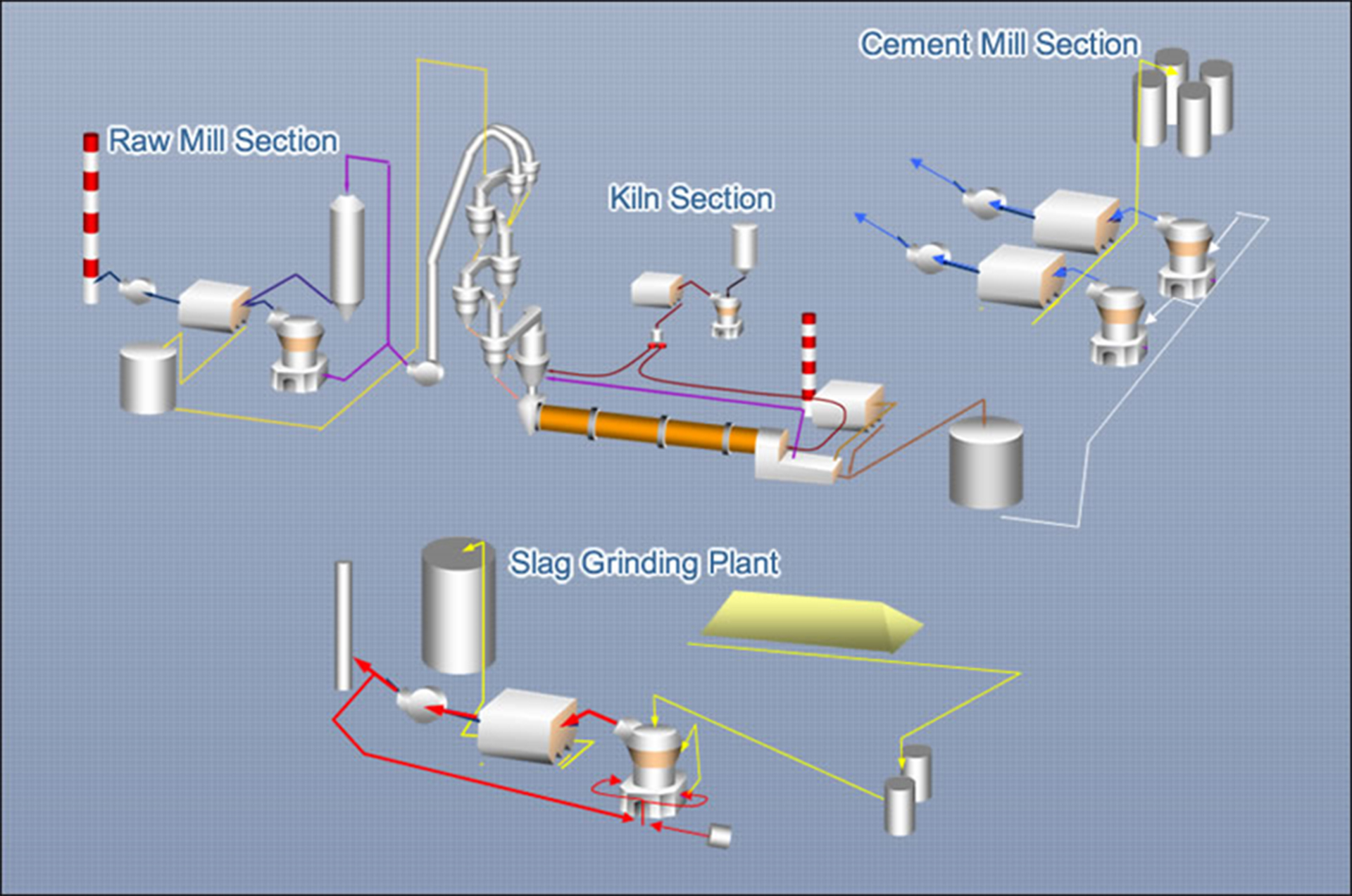

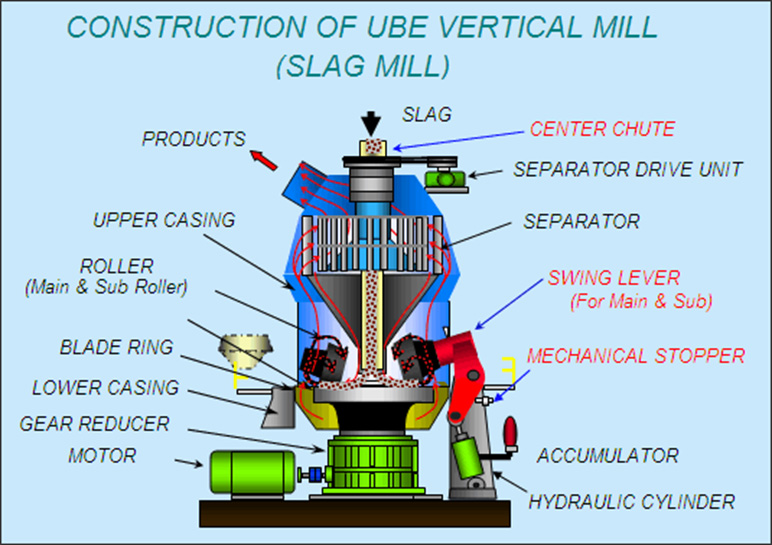

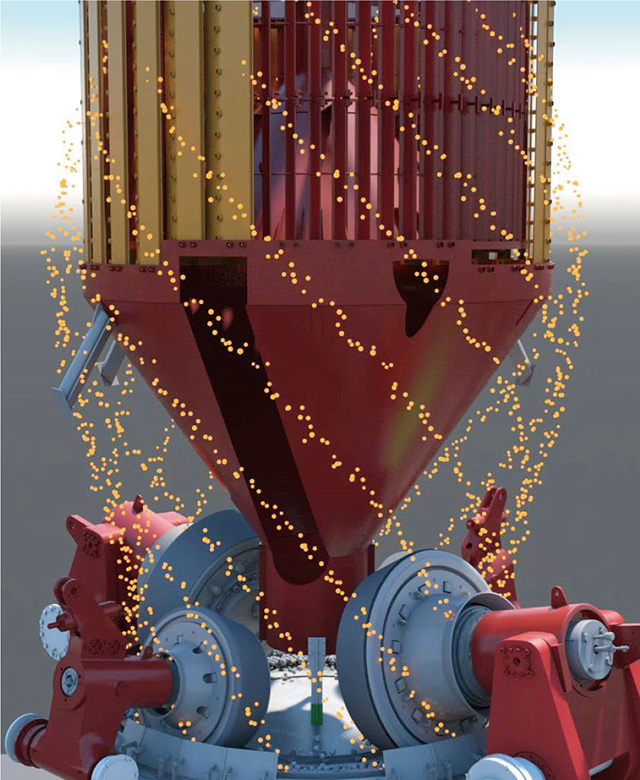

Structure of UBE Vertical Mill and grinding principle

STEP1

The mill motor is rotating the table via a gear reducer.

Raw materials are supplied onto the table through the chute and spead to the outer table by the centrifugal force.

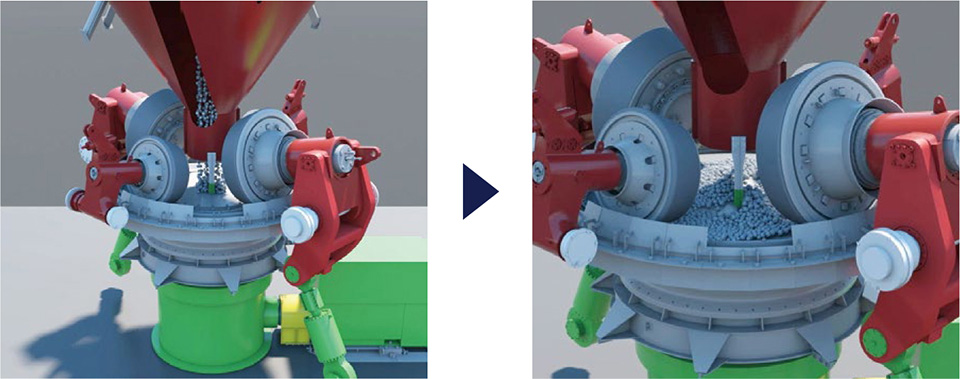

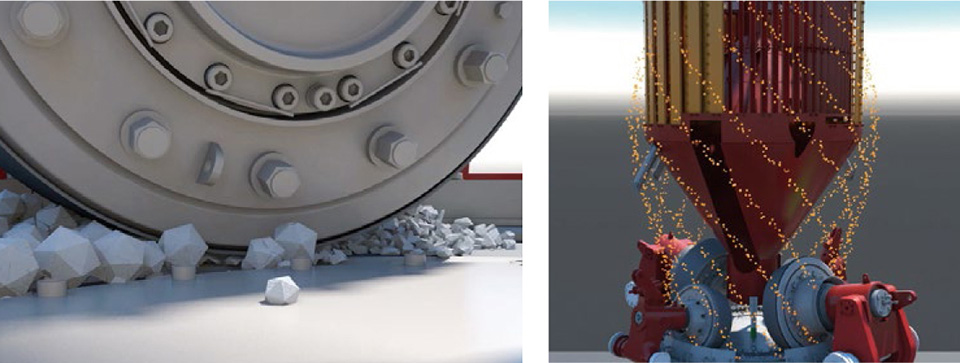

STEP2

At the outer of table, the materials are ground by roller which pressed by hydraulic pressure. Ground material drying by hot air are blown up to separator.

STEP3

By the rotating rotor, the raw material is classified into required particle size by the balance between the centrifugal force and the air flow force passing through the rotor.

STEP4

Fine particle which passing through the rotor is taken as product, Coarse particle are rejected by centrifugal force and return to grinding table then grind again.

Particle size can be adjusted by rotating speed of separator.

Unique vibration absorption technology

When grinding fine products and slippery materials, vibration will occur by the roller slipping. We have unique technology to use as a countermeasure for that vibration.

1. Variable speed control for table rotation

Vibration is avoided by a variable speed control table rotation by an inverter motor. Especially its effect on fine products such as slag and slippery materials like oil cokes.

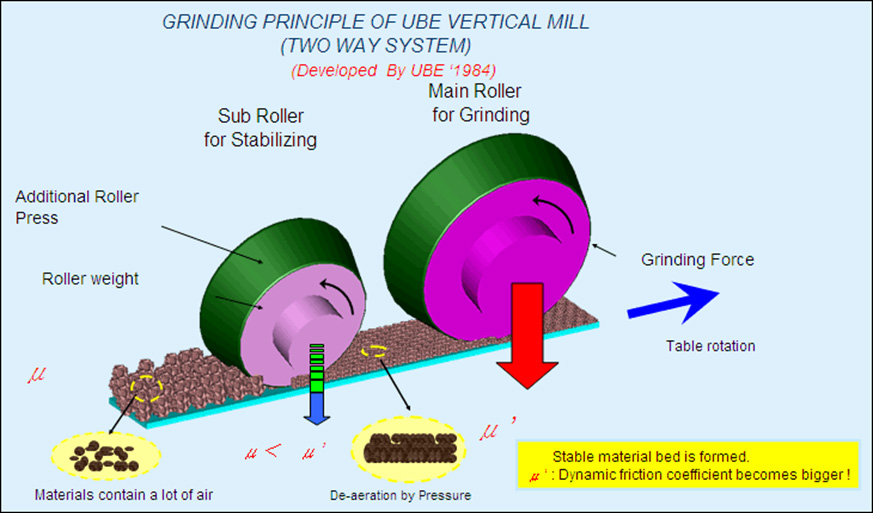

2. 2-way System

For making a stable grinding bed between the roller tire and table liner, UBE Slag Grinding Mill adopts a '2-Way System'.

By adopting this '2-Way System', our mills are operated under less vibration achieving better performance.

Features of the UBE Vertical Mill

By performing the three processes of grinding, drying, and classification at the same time, we can respond to the high quality and energy saving of raw material fine powder processing technology required in all fields.

1. Running cost reduced

High efficiency of pulverization and low power consumption lead to a reduction in electric cost by 40-50% compare to ball mill.

2. Construction cost reduced

Since the drying, grinding and classifying operation are performed simultaneously, the system configuration is simple. The vertical mill allows the installation area to be decreased, leading to a reduction of construction cost.

3. Easy operation

Material feed, grinding force, air volume and separator feed can be adjusted through a remote control system, which makes the operation easier.

4. Simple maintenance

The roller tires and table liners can be replaced in a short time simply by reversing the swing lever.

5. Environmentally friendly

The UBE vertical mill produces less vibration and noise than other grinding mills.

6. Uniform quality of products

The highly efficient grinding mechanism and classifier are equipped to provide the more stable particle size distribution than other roller mills.

Applications of UBE Vertical Mill

Information about UBE Vertical Mill services

Repair Service

Restoring your equipment to its original performance.

Consulting Service

Maximizing your equipment performance.

Upgrade Service

Further expanding the capabilities of your equipment.