UBE Machinery's Injection Molding

“High-Performance Molding”

UBE Machinery offers a diverse lineup of molding systems that support a variety of molding methods and products.Our multi-color/multi-material molding system, which integrally molds resins of different colors and materials, reduces post-molding assembly and painting processes, and improves design and functionality.

Integrated Skin Molding

UBE Machinery offers technologies that reduce post-molding assembly and painting processes and improve design and functionality at low cost.

We support customers' product development and stable production with our extensive experience and molding technology in integrated skin molding, which increases the added value of products.

DIEPREST

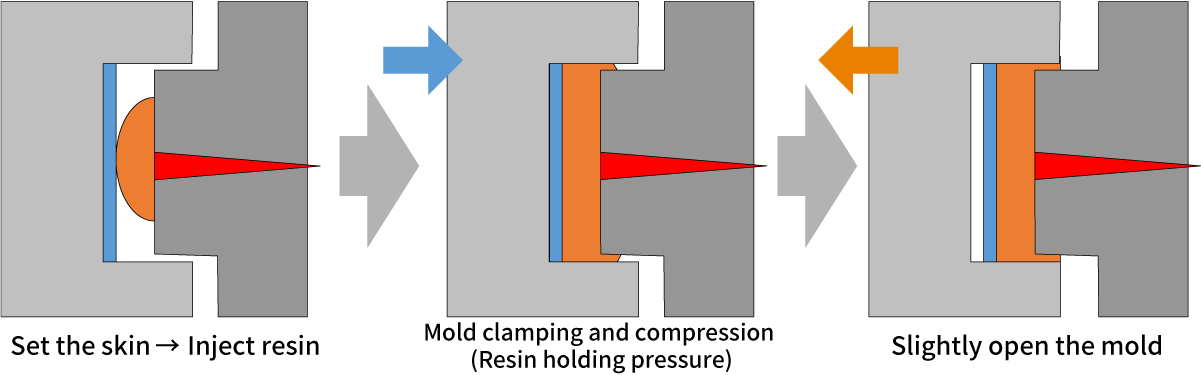

We have developed a molding technology that achieves self-healing of damage to skin material in the surface skin lamination molding of resin products such as automotive interior parts using the ultra-precision die open/close control DIEPREST. This technology reduces the production process of plastic parts while ensuring high quality.

Surface skin decorative molding : Self-healing of surface skin material damage

High Design Molding

Multi-color and multi-material molding reduces post-molding assembly and painting processes and improves design and functionality.

Base resin + Transparent resin “Glitter decoration”

Weldless molding

Piano black decoration

3D decoration

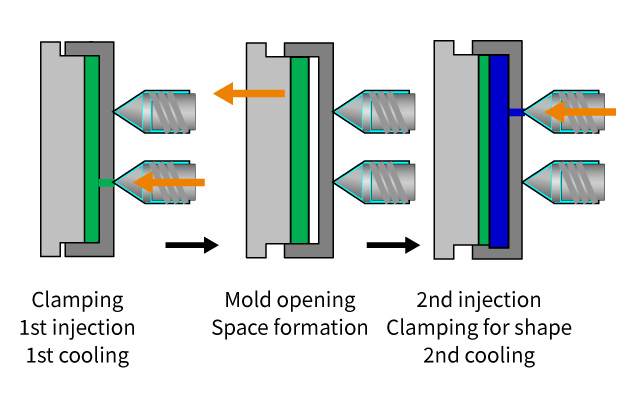

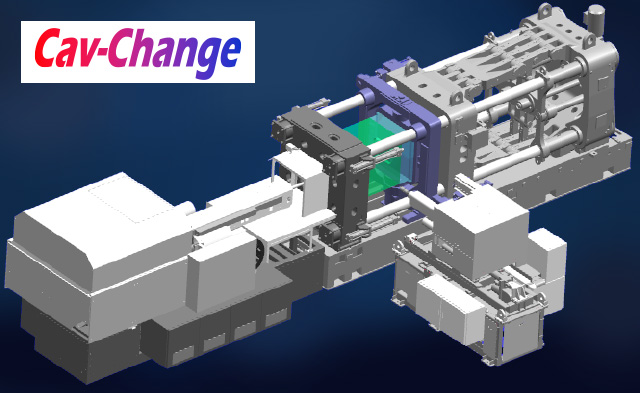

(1) 1-cavity method

This is a 1-cavity molding method in which the second material is filled after the mold is slightly opened using DIEPREST.

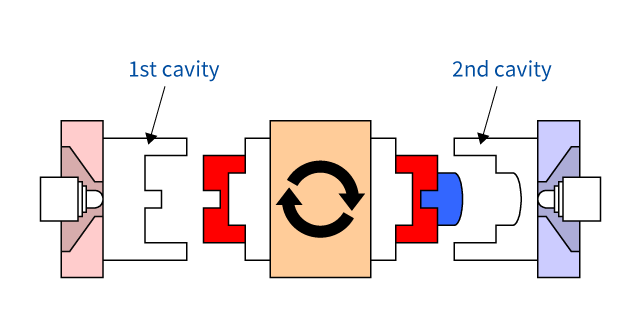

(2) 2-cavity method

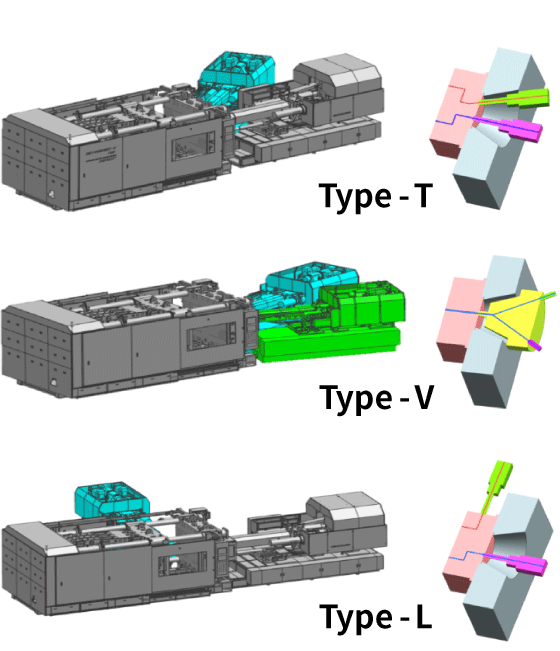

This is a molding method in which two molds, one with a cavity structure for the first material and the other for the second material, are mounted, and the core side of these molds is rotated.

UBE Machinery's injection molding machine for 1-cavity of mold

Two-material injection molding machine

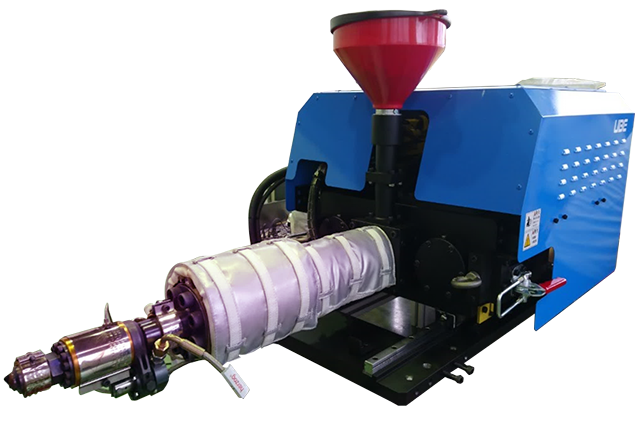

Ultra-compact injection unit "Putit Injection"

UBE Machinery's injection molding machine for 2-cavities of molds

All-electric toggle type : UF/HH series

Electric 2 platen type : emR series