UBE Machinery's Injection Molding

“Material Recycling Technology”

UBE Machinery contributes to society from the perspective of SDGs by proposing molding systems that solve the problems of recycled materials.

Multi-material injection molding

Sandwich molding

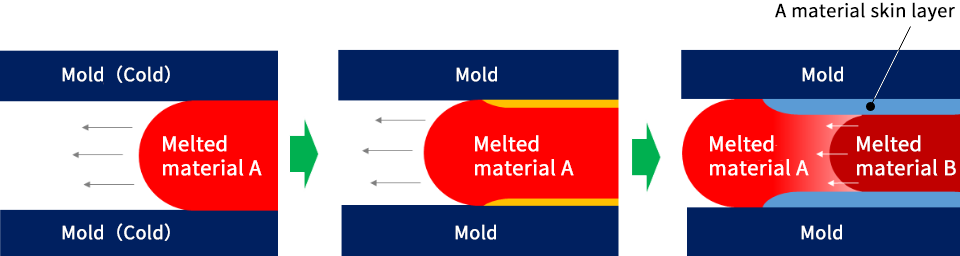

By having different resins independently injection-filled in the mold and using recycled materials in the product (core layer), material recycling is possible while maintaining conventional product appearance quality.

Material A is cooled by the mold and gradually solidifies, creating a skin layer on the contact surface with the mold.

Material B flows inside material A (between the skin layers) and is sealed without leaking outside the molded product.

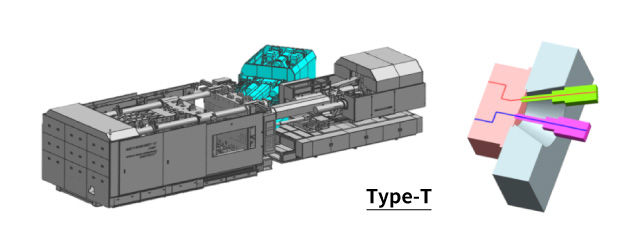

Sandwich injection molding system

Co-injection Standard

Co-injection Standard is a molding machine with two injection units in one machine.

Injection unit layout can be adapted according to the mold structure and factory installation space.

“Putit Injection”

Compact electric-driven injection unit that is compatible with all models of our injection molding machines and can be added to other manufacturers' machines. Compared to conventional sandwich molding systems, there are fewer placement restrictions, and multiple units can be installed to pursue the molding of high value-added products, including multiple or different materials.

*“Putit Injection” is a registered trademark of UBE Machinery in Japan.

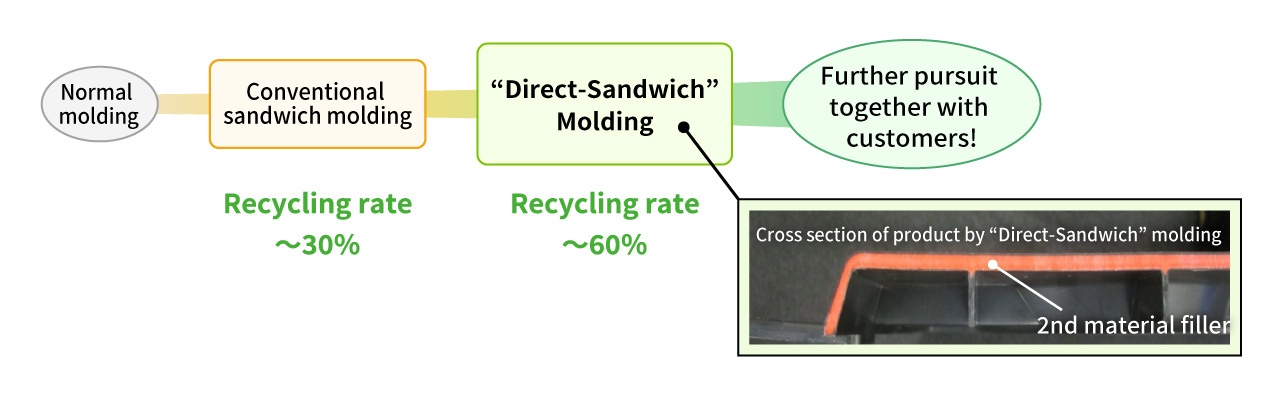

UBE Machinery's “Direct-Sandwich” Injection Molding

Compared to conventional sandwich molding, the recycling rate can be dramatically improved.

This is our original molding method that can be realized by adding our proprietary DIEPREST ultra-precision mold opening/closing control to the conventional sandwich molding system.

“Direct-Sandwich”: Registered trademark of UBE Machinery in Japan

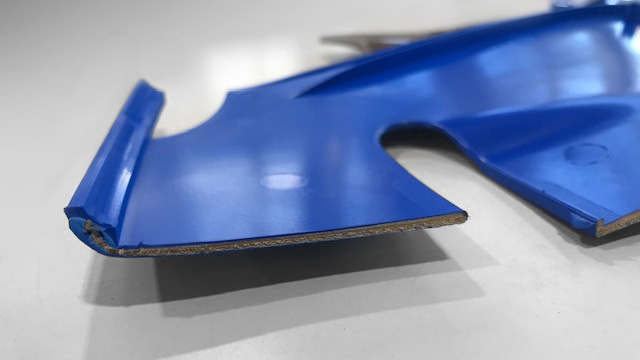

Example of biomass plastic molding

(Resin) PP: 50% +

cedar wood (wood powder): 50

(Photo provided by)

HODEN SEIMITSU KAKO KENKYUSHO CO.,LTD.

Seiko Resin Co.,Ltd.

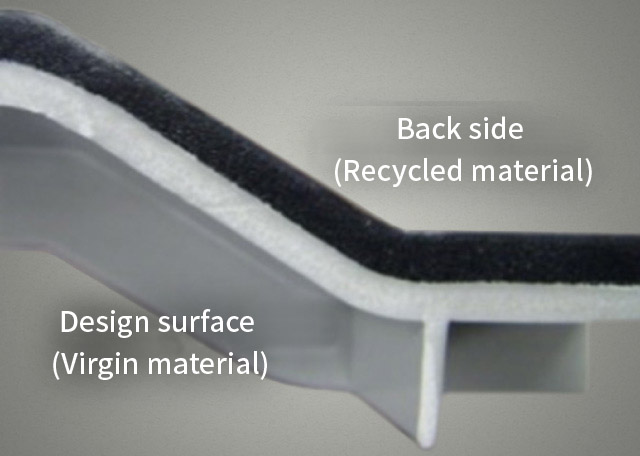

Laminated molding

This is a molding method in which recycled materials are used on the back of the product and different materials (conventional materials) are laminated on the design surface.

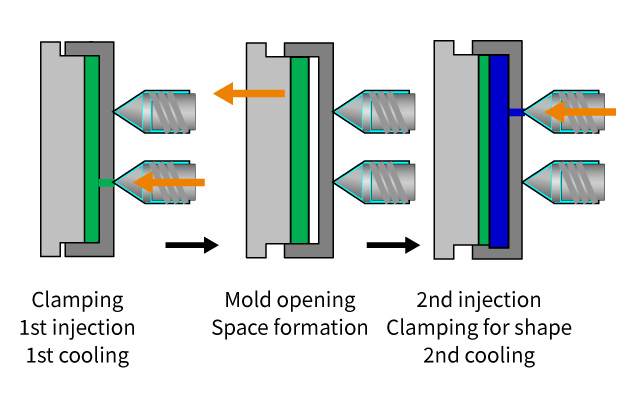

(1) 1-cavity method

This is a 1-cavity molding method in which the second material is filled after the mold is slightly opened using DIEPREST.

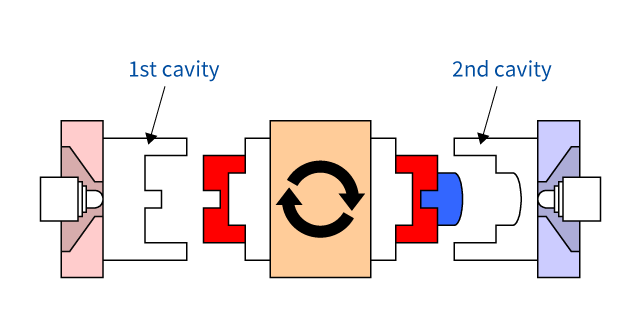

(2) 2-cavity method

This is a molding method in which two molds, one with a cavity structure for the first material and the other for the second material, are mounted, and the core side of these molds are rotated.

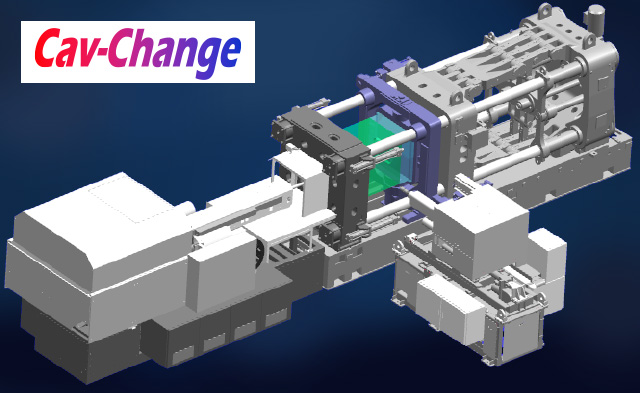

UBE Machinery's injection molding machine for 2-cavities of molds

All-electric toggle type : UF/HH series

Cav-Change

Cav-Change: UBE Machinery's registered

trademark in Japan

Screws for Recycled Materials

We offer screws with excellent plasticization stability, additive mixing, and degassing properties that have a proven track record in a wide variety of recycled material shapes.