UBE Machinery's Injection Molding

“Molding Defect Improvement Technology”

UBE Machinery offers solutions using our technologies that can contribute to customers' improvement activities from the investigation of the cause of molding defects to the improvement of the defects.

Improvement of gas release defects

AIRPREST

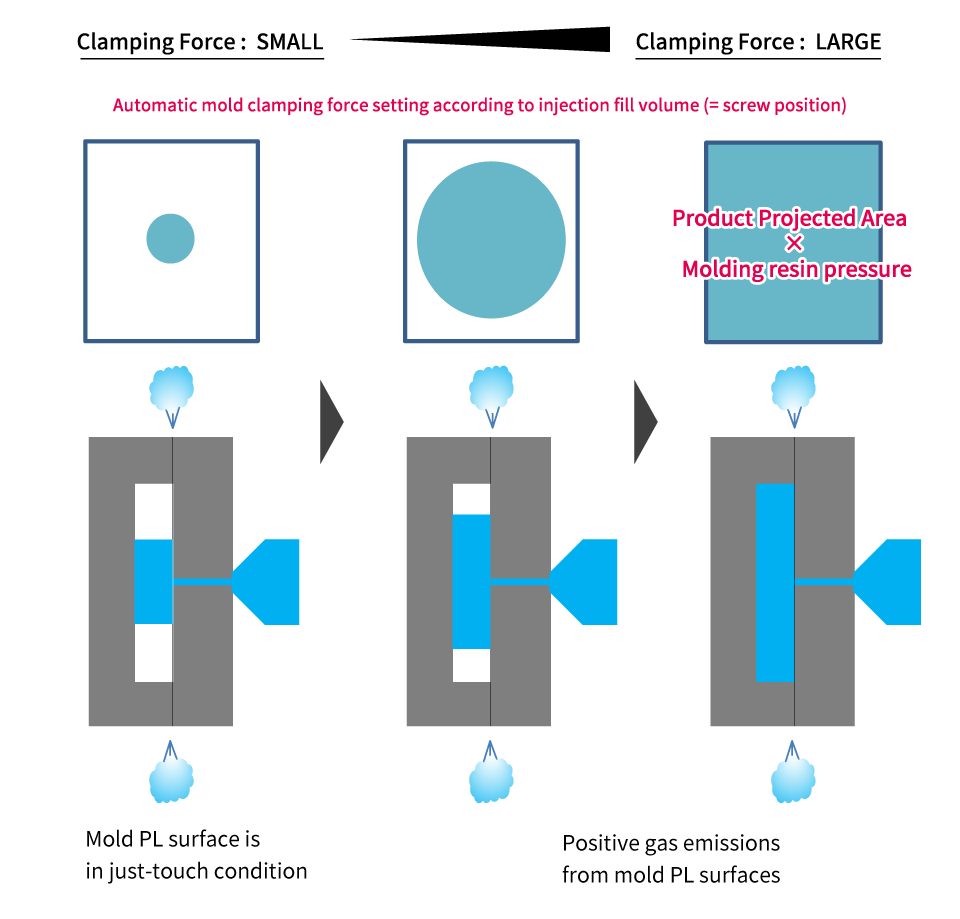

This is "mold degassing molding" that improves "gas release defects" by controlling the air in the mold through optimal mold clamping according to injection filling and optimal mold clamping cooling suited to the mold.

In addition to improving defects, AIRPREST also contributes to improved cooling of the molded product inside the mold, enabling high-cycle molding.

Clamping force setting: Injection filling area × molding resin pressure

Improvement of deformation defects

DIEPREST

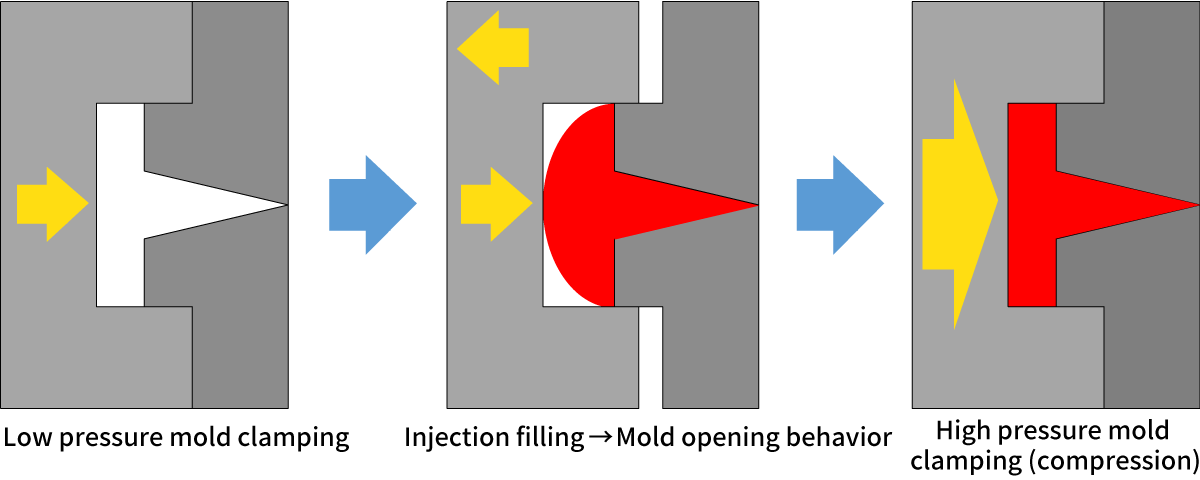

DIEPREST, an ultra-precise mold open/close control system, reduces warpage and sink marks by relieving internal stress of the resin in the cavity during filling.

Injection compression molding: Reduction of product warpage deformation

Improvement of color irregularity defects

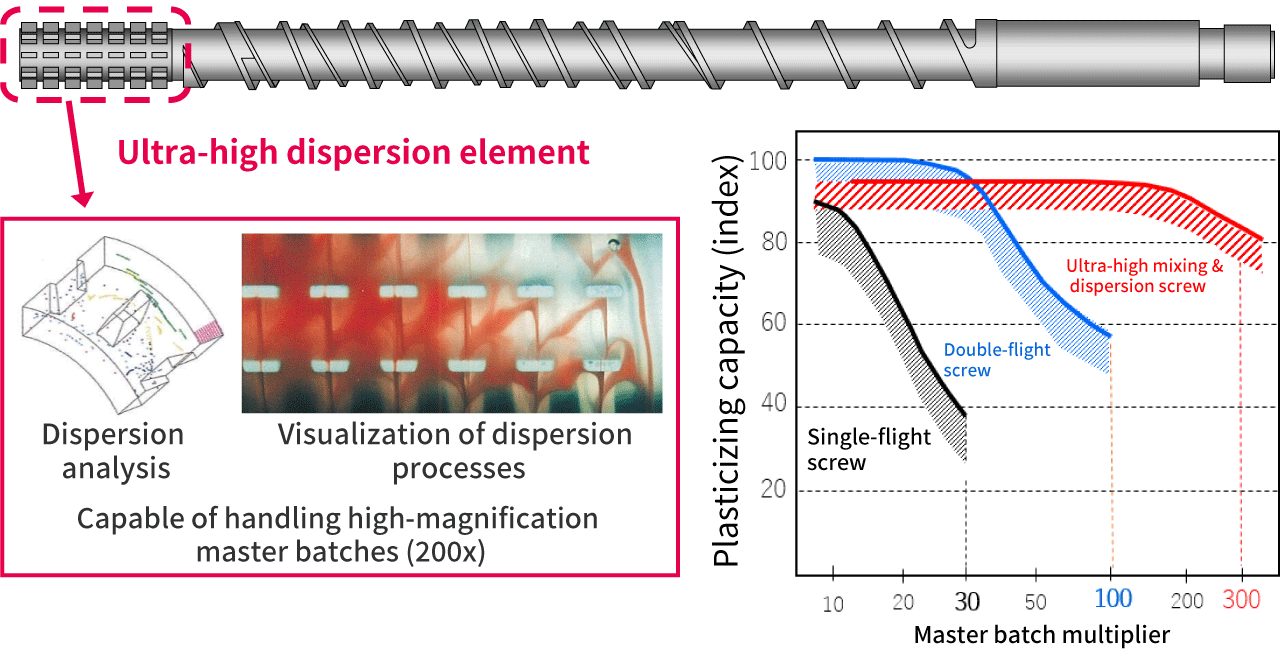

Ultra-high mixing & dispersion screw

In order to increase productivity, it is common practice to increase plasticizing capacity by increasing screw speed, but this leads to poor mixing and dispersion.We will introduce an ultra-high mixing and dispersion screw that can ensure high dispersibility without compromising plasticizing capacity, contributing to high productivity and high-quality molding for our customers.

Improvement of black spots and discoloration defects

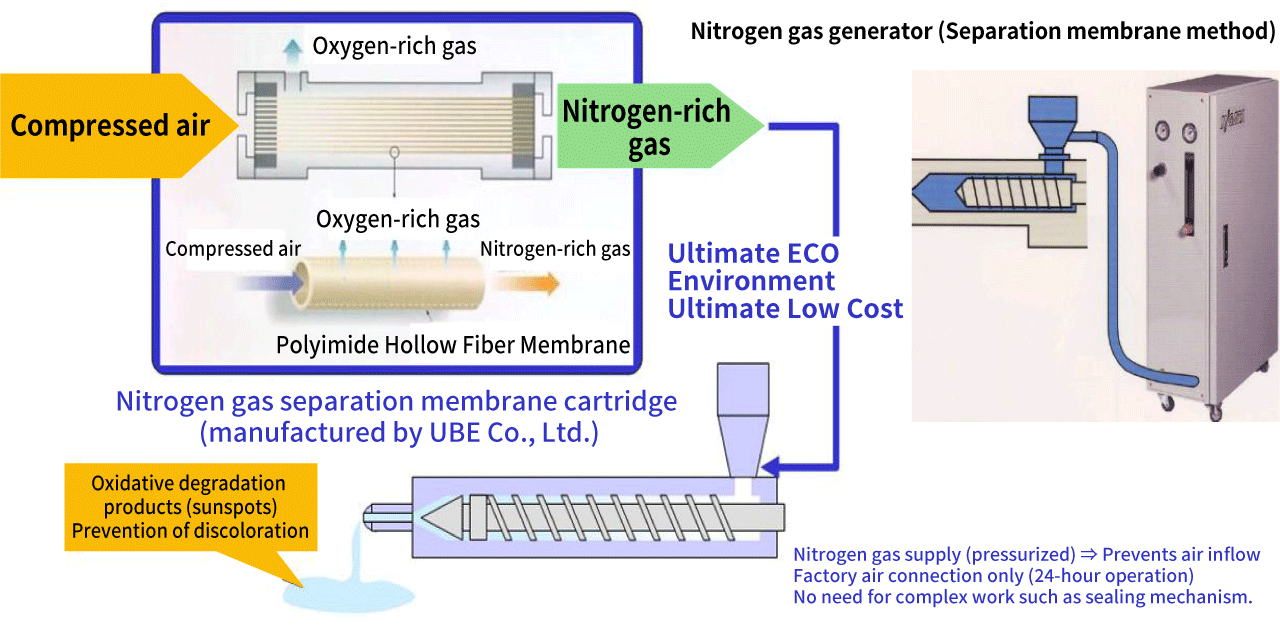

Nitrogen Gas Displacement Unit

This system extracts nitrogen from the atmosphere and supplies nitrogen gas into the barrel.

By replacing oxygen in the barrel, which is a factor in resin degradation, with nitrogen, oxidative degradation of resin can be reduced.

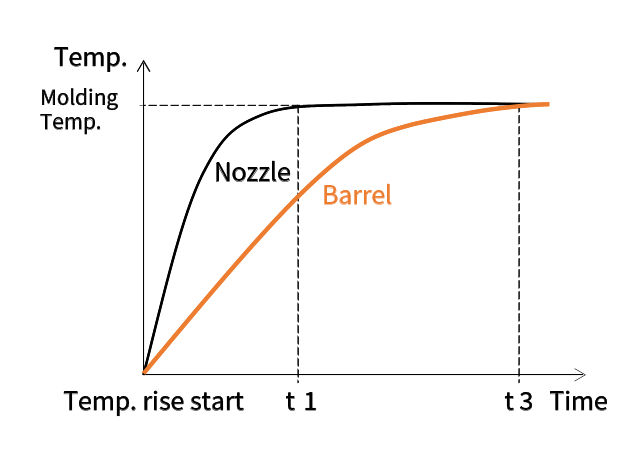

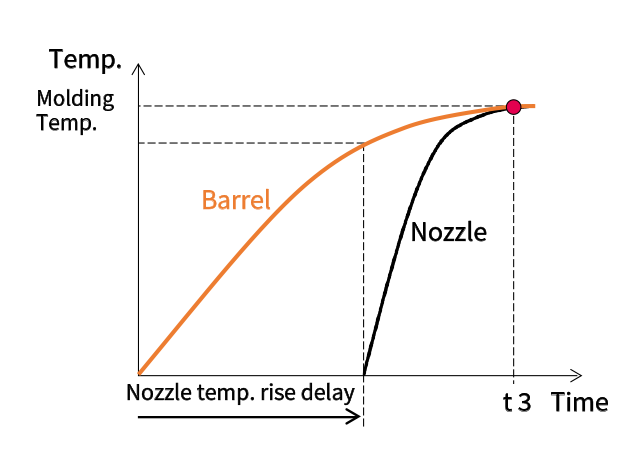

Simultaneous nozzle and barrel heat-up circuit

By matching the timing of the completion of heat-up of nozzles and barrels with different heat-up rates, the resin in the nozzles and barrels is exposed to high temperatures for a shorter time, thereby reducing degradation due to thermal decomposition.

Materials and Surface Coatings for Resin Flow Paths

We propose materials and surface coatings for the plasticized parts that make up the resin channel, in accordance with the characteristics of the materials used and the molding environment.