UBE Machinery’s Injection Molding

“Equipment Cost Reduction”

We propose technologies to reduce capital investment by consolidating production facilities, including machine model selection that maximizes the performance of molding machines and auxiliary equipment.

Equipment Consolidation

We propose high-performance molding technologies to maximize the use of customer's factory layout.

SCS Molding (Sequential Cavity Separation)

This is UBE Machinery's control technology for efficiently molding multiple product groups on a single molding machine. SCS molding uses UBE Machinery's proprietary multiple injection control algorithm to sequentially inject multiple products, achieving high quality and repeatability for each product with minimal mold clamping force.

SCS: Registered trademark of UBE Machinery in Japan

Machine size class reduction

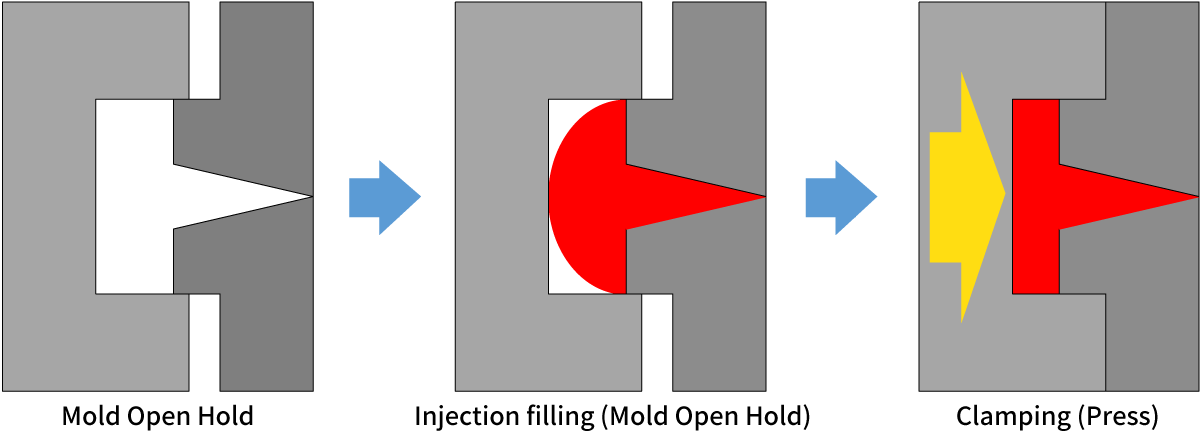

DIEPREST

Low-pressure injection and low mold clamping using the ultra-precision die open/close control DIEPREST functionality can downgrade the required machine size class.

DIEPREST molding: Low clamping force molding

| Size of Flat plate (Molded product) |

Product Dimensions H x W (mm) |

Required clamping force (tonf) | |

| Normal molding | DIEPREST molding | ||

| 32 inch | 410 x 720 | 1330~ | 740 |

| 40 inch | 520 x 920 | 2150~ | 1200 |

| 46 inch | 590 x 1110 | 2900~ | 1650 |

| 52 inch | 670 x 1170 | 3500~ | 2000 |

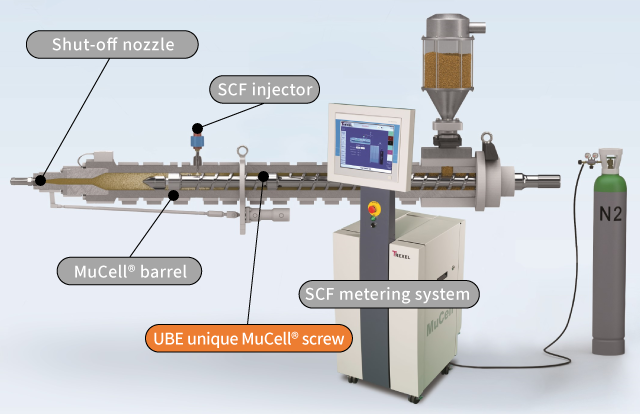

*MuCell® is a registered trademark of TREXEL, Inc.

MuCell® molding enables gas to dissolve into the resin at supercritical pressure, which reduces the viscosity of the resin in proportion to the amount of gas dissolved, and thus reduces the filling pressure during injection, which in turn reduces the required mold clamping force.

| MuCell® | Chemical foaming | ||

|---|---|---|---|

| Foaming Gas | Type | CO2 or N2 | CO2 |

| Dissolved amount (concentration) | Large | Small | |

| Resin viscosity | Large | Small | |

| Filling pressure reduction effect | Large | Small | |

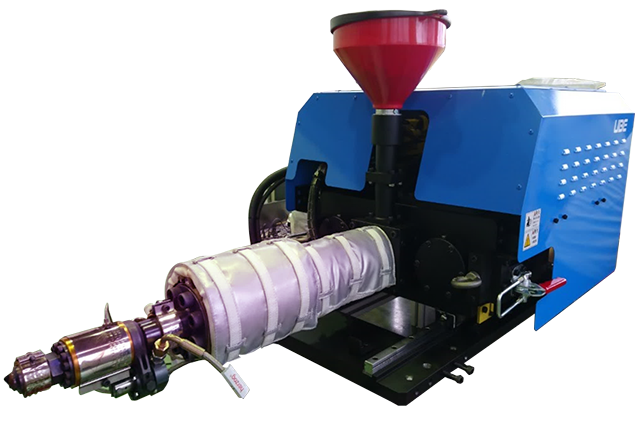

Easy add-on multi-material molding

Ultra-compact injection molding system "Putit Injection" directly attached to the mold

By docking UBE Machinery's "Putit Injection" to your existing injection molding machine, you can easily convert it into a co-injection (two-color molding machine). Not only UBE machines, but also other companies' molding machines can be installed.

- Ultra-compact electric-driven injection unit (injection capacity 50-250cc).

- Directly mounted on the mold for small-quantity, multi-color molding.

- Standard injection molding machine turns into a multi-color molding machine.

- More versatile and space-saving than two-material injection molding machines.